Planting-type hydroxyapatite filter particles based on planting method for defluoridation water treatment and preparation method thereof

A hydroxyapatite and water treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, ion-exchanged water/sewage treatment, etc. The problem of high cost, to achieve the effect of simple equipment, improved processing efficiency and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

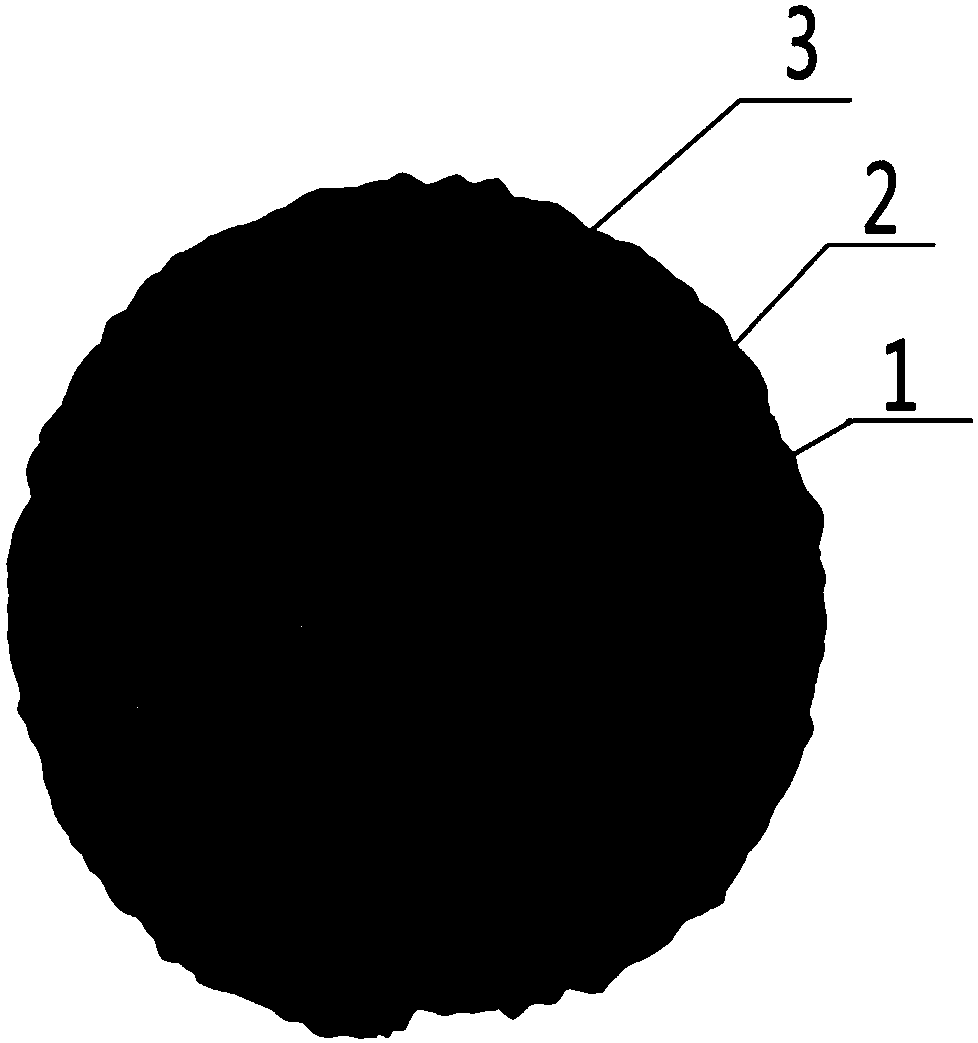

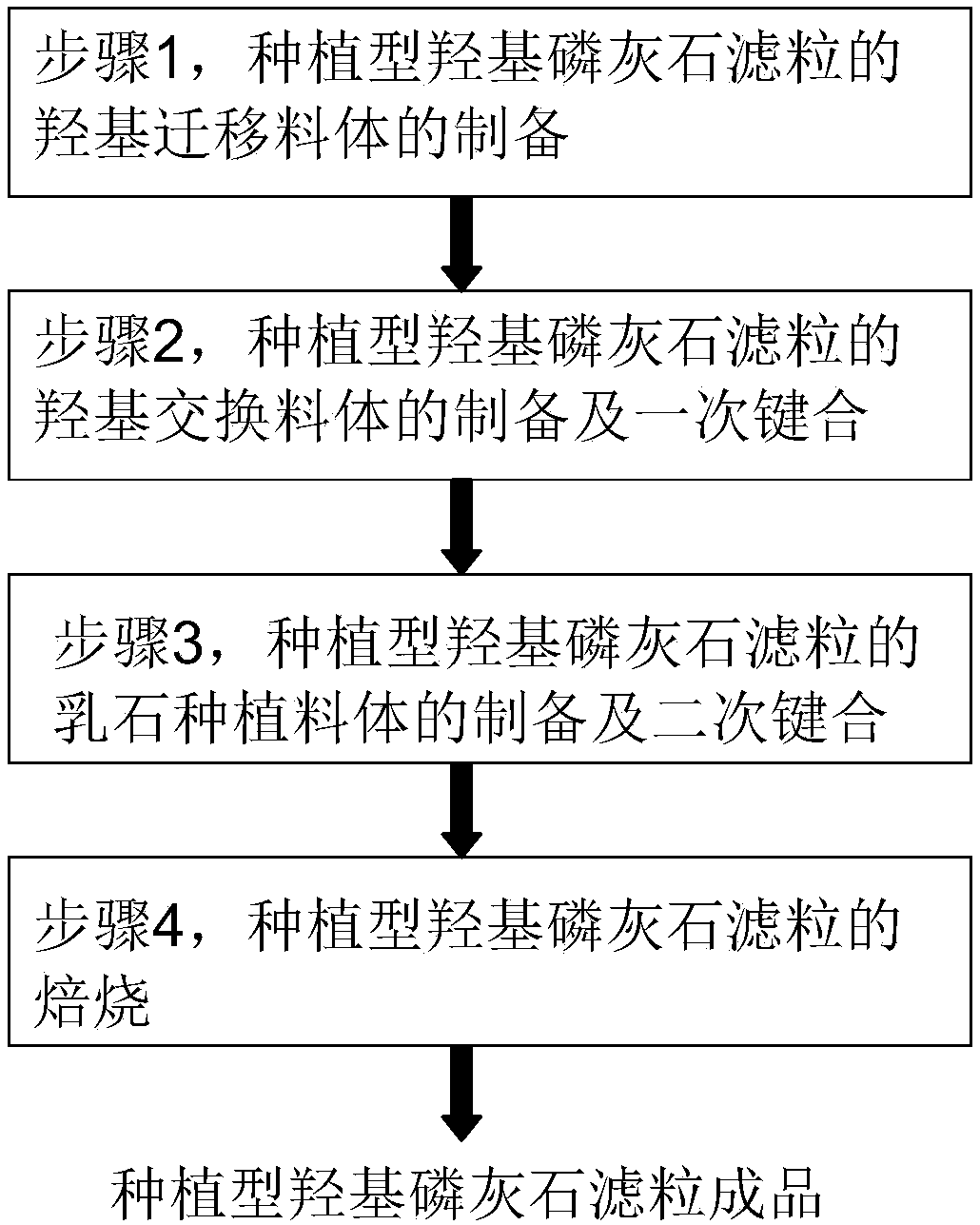

[0032] combine figure 1 , figure 2 and image 3, a method for preparing planted hydroxyapatite filter grains based on the planting method for defluoridation water treatment proposed by the present invention is characterized in that the method is based on the self-filtration in the structure of the planted hydroxyapatite filter grains From the inner core to the outer surface of the grain, it is divided into the inner core planting layer 1, the transitional planting layer 2 and the outer planting layer 3 in order according to the increase of the hydroxyl content, and the chemical bonding between the adjacent two layers; wherein: the inner core planting layer 1 The main body is the hydroxyl migration material body of the planting type hydroxyapatite filter grain; the main body of the transition planting layer 2 is the hydroxyl exchange material body of the planting type hydroxyapatite filter grain; the main body of the outer planting layer 3 is the planting type The milk stone...

Embodiment 1

[0058] (1) The main body of the core planting layer 1 of the planting type hydroxyapatite filter grain is the hydroxyl migration material body, according to the component content of the hydroxyl migration material body in wt %: 35 parts of hydroxyapatite powder, 40 parts of attapulgite powder , 13 parts of bentonite powder, 9 parts of oxalic acid powder and 3 parts of carboxymethyl cellulose; through a 140 mesh sieve, the thickness of the inner core planting layer 1 is controlled to be 0.5mm during the molding process;

[0059](2) The main body of the transitional planting layer 2 of the planting type hydroxyapatite filter grain is the hydroxyl exchange material body, according to the component content of the hydroxyl exchange material body in wt %: 50 parts of hydroxyapatite powder, 34 parts of attapulgite powder , 12 parts of malonic acid powder and 4 parts of water glass; through a 140 mesh sieve, the thickness of the transitional planting layer 2 is controlled to be 0.3mm d...

Embodiment 2

[0064] (1) The main body of the core planting layer 1 of the planting type hydroxyapatite filter grain is the hydroxyl migration material body, according to the component content of the hydroxyl migration material body in wt %: 50 parts of hydroxyapatite powder, 36 parts of attapulgite powder , 10 parts of bentonite powder, 3 parts of glutaric acid powder and 1 part of water glass; through a 270 mesh sieve, the thickness of the inner core planting layer 1 is controlled to be 1.5mm during the molding process;

[0065] (2) The main body of the transitional planting layer 2 of the planting type hydroxyapatite filter grain is the hydroxyl exchange material body, according to the component content of the hydroxyl group migration material body in wt %: 65 parts of hydroxyapatite powder, 27 parts of attapulgite powder , 6 parts of succinic acid powder and 2 parts of water glass; through a 270 mesh sieve, the thickness of the transitional planting layer 2 is controlled to be 0.5mm duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com