Preparation method of parallel array multi-core fiber

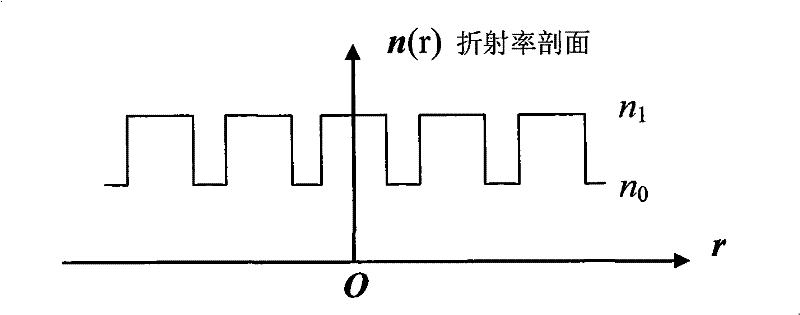

A technology of multi-core optical fiber and array optical fiber, which is applied in the direction of multi-layer core/clad optical fiber, clad optical fiber, glass manufacturing equipment, etc., to achieve the effect of easy control of processing size, same optical performance, and avoid inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in more detail below in conjunction with accompanying drawing example:

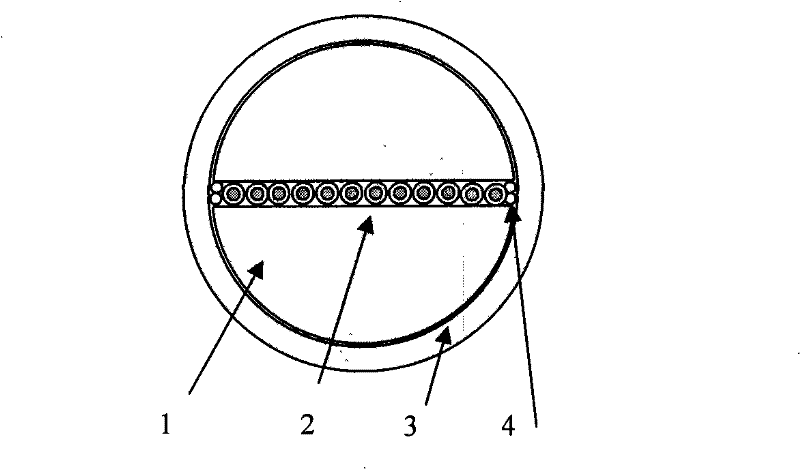

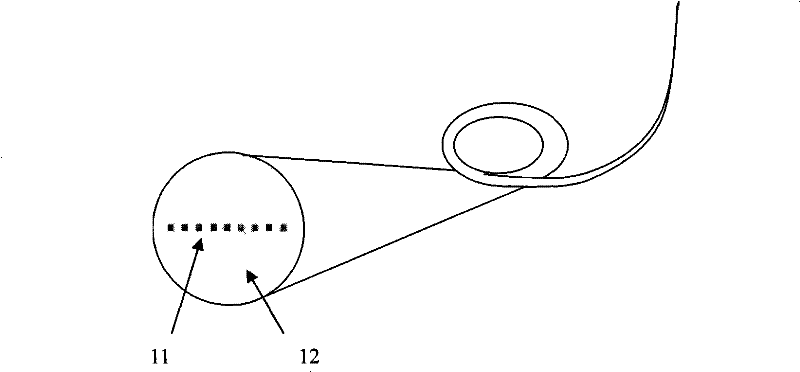

[0029] to combine figure 1 , the preparation process of the parallel array optical fiber preform is as follows: first, the high-purity quartz glass rod is cut in half along the diameter direction with a glass cutting machine to obtain two semi-cylindrical quartz glass rods. The cut surfaces of the two quartz glass rods are then ground to form two D-type glass quartz rods 1 . The ground-off dimensions of the two D-glass rods should be the same, and the sum of the ground-off dimensions of the two D-glass rods should be equal to the diameter of the optical fiber core member to be inserted. Take the specially prepared optical fiber ferrule member, and cut out several sections of the same length of the optical fiber core member in sections. The optical fiber core components 2 are filled between the two D-shaped glass rods, so that the optical fiber core components a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com