Device for preventing water hammer damage after positive displacement diaphragm pump accident and control method

A control method and diaphragm pump technology, applied in pump control, components of pumping devices for elastic fluids, pumps, etc., can solve problems affecting production organization, increasing maintenance costs of main pumps, and large damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

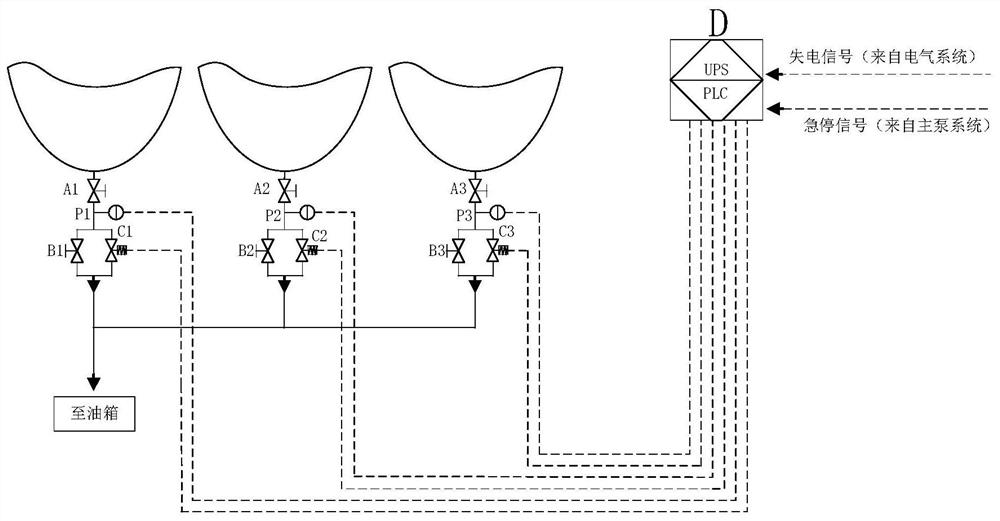

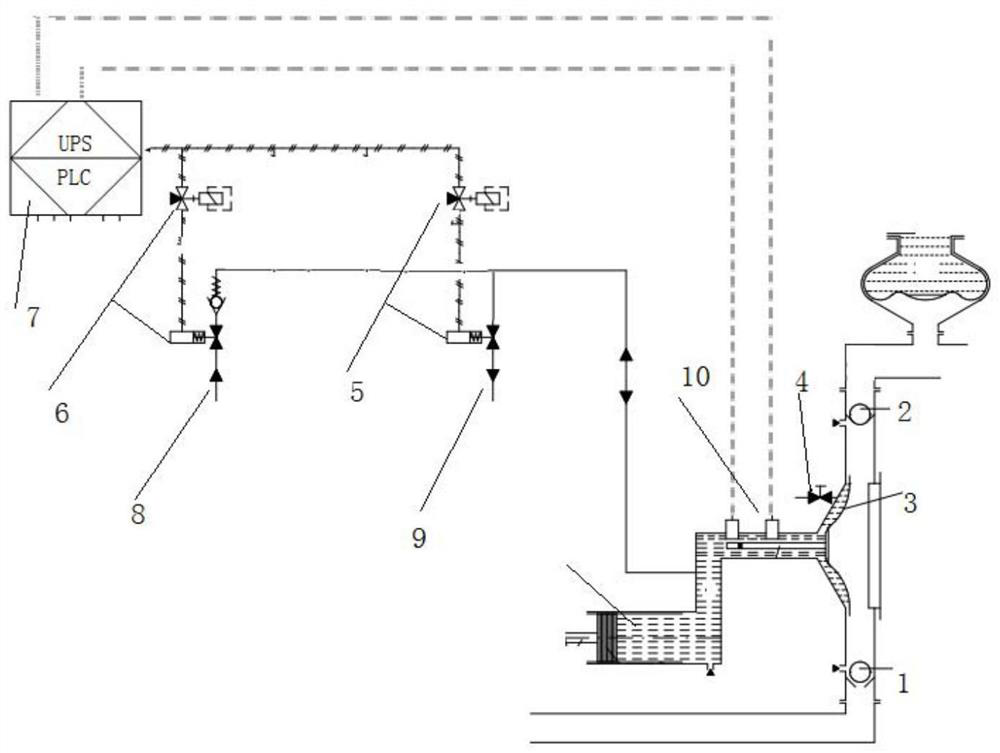

[0023] Such as Figure 1-2 As shown, three diaphragm chambers are selected for the main pump in this embodiment, and the piston chamber with the highest pressure is released in time when the three piston rods of the main pump lose power, so that the corresponding outlet one-way valve is closed in time to ensure that the counterattack zone generated by the pipeline water hammer coming pressure imbalance;

[0024] In this embodiment, a manual discharge valve is provided on the propulsive liquid side of the diaphragm chamber, and a three-way is installed on the manual discharge valve to form a total discharge channel and two branch discharge channels of the diaphragm chamber. It is characterized in that a manual discharge valve is set on the one branch discharge channel , and a high-pressure solenoid valve is set on the other branch discharge channel;

[0025] In this embodiment, a diaphragm chamber manual total discharge valve and a pressure sensor are installed on the total di...

Embodiment 2

[0030] Such as Figure 1-2 As shown, when the diaphragm pump in this embodiment is in normal operation, A1, A2, and A3 are in the normally open state; B1, B2, and B3 are in the closed state; C1, C2, and C3 are in the power-off and closed state; P1, P2, and P3 are detected in real time The pressure of three diaphragm chambers; D is with UPS control system, the port is connected with the pressure sensor to control the device in real time;

[0031] In this embodiment, A1, A2, and A3 are the total discharge valves of the three diaphragm chambers, and a manual needle valve is selected. This valve is used as the main valve for maintenance and is always in a normally open state; when the back-end valve (B or C series valve) or When the pipeline fails and needs to be repaired and replaced, close the valve to temporarily cut off the oil circuit; after the inspection is completed, manually open the valve, and the staff will observe the smoothness of the oil circuit and the pressure valu...

Embodiment 3

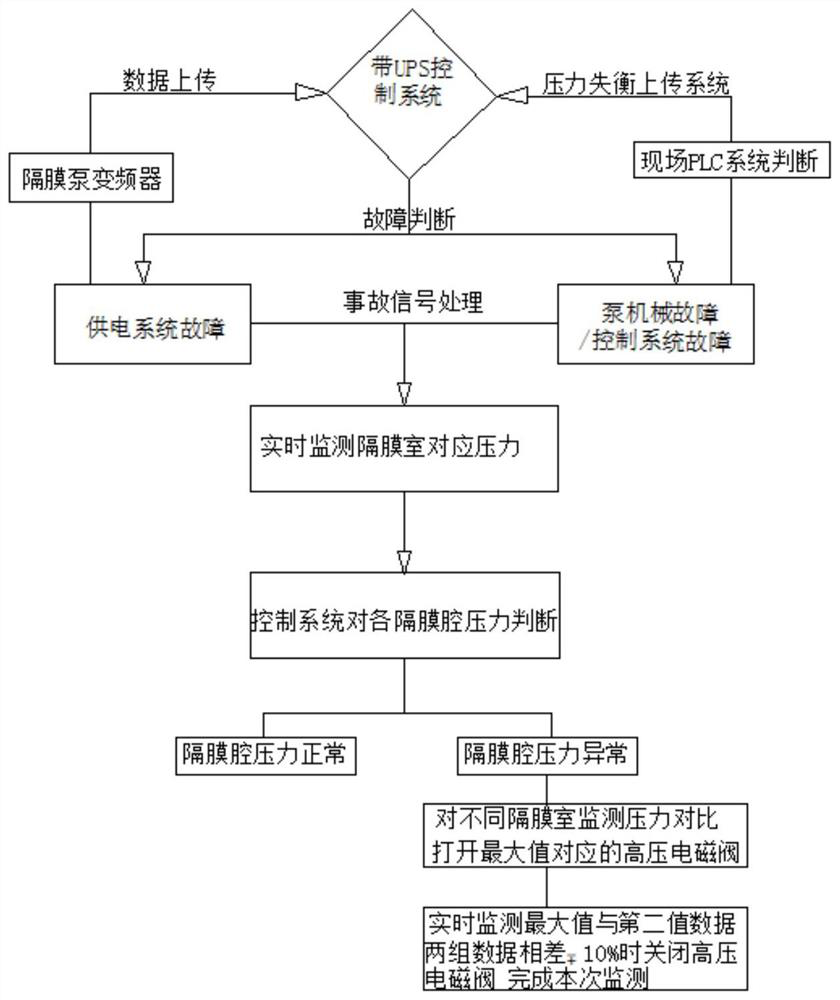

[0035] Such as Figure 1-3 As shown, in this embodiment, the C series high-pressure solenoid valve is monitored in real time by the pressure sensor through the control system with UPS, and is normally closed;

[0036] In this embodiment, after the accident occurs, the UPS control system receives signals to judge the fault. (1) The system judges that the power supply system is faulty, and the main power loss signal is introduced into the UPS control system by the diaphragm pump inverter system; one end of the high-voltage solenoid valve is connected to The UPS connection port with UPS control system, even if the power fails, it can be powered by the UPS power supply alone, and the high-voltage solenoid valve will not be opened normally due to the power failure;

[0037] (2) The system judges that it is a mechanical failure of the pump or a failure of the control system. The emergency shutdown signal of the diaphragm pump is pre-judged by the on-site PLC system. If it is judged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com