Perspiration antibacterial cool fabric and preparation method thereof

A cool-feeling fabric and cool-feeling technology, applied in the processing of textile materials, liquid/gas/vapor textile material processing, yarn, etc., can solve problems such as affecting heat and moisture exchange, affecting human health, breeding bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

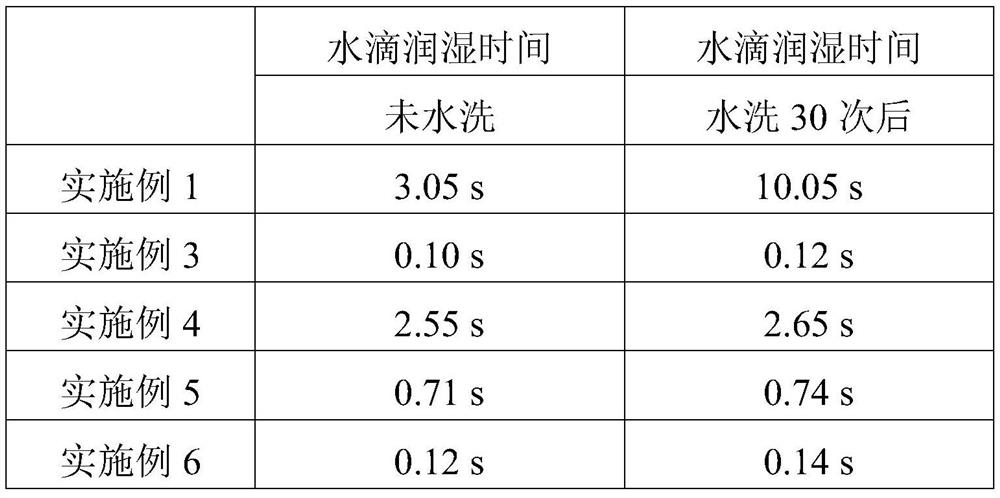

Examples

Embodiment 1

[0058] A preparation method for perspiration antibacterial cool feeling fabric, comprising the following steps:

[0059] (1) After mixing Coolmax fiber and LYOCELL fiber at a mass ratio of 40:45, weave blended yarn on a small rotor spinning machine (model YHF1618A, Jinzhong Tianyu Textile Machinery Parts Co., Ltd.) by conventional technology to control the yarn line The density is 36tex, and the functional yarn-the main yarn of the fabric is obtained; the bamboo dyer fiber is woven into a yarn on a small rotor spinning machine (model YHF1618A, Jinzhong Tianyu Textile Machinery Parts Co., Ltd.) through a conventional process, and the yarn line is controlled. Density is 15tex, antibacterial yarn-fabric auxiliary yarn;

[0060] (2) The functional yarn and the antibacterial yarn in the step (1) are weaved with a weft knitting single-sided large circular machine (model TF-S3F2 / 4, Fujian Taifan Industrial Co., Ltd.) for plain stitching, In the flat needle plating structure, the ant...

Embodiment 2

[0064] A preparation method for perspiration antibacterial cool feeling fabric, comprising the following steps:

[0065] (1) After mixing Coolplus fiber and cupro ammonia fiber according to the mass ratio of 35:60, it is spun into a blended yarn on a small rotor spinning machine (model YHF1618A, Jinzhong Tianyu Textile Machinery Parts Co., Ltd.) through a conventional process, and the yarn is controlled The linear density is 36tex, and the functional yarn-fabric main yarn is obtained; the X-STATIC nylon fiber is woven into a yarn on a small rotor spinning machine (model YHF1618A, Jinzhong Tianyu Textile Machinery Parts Co., Ltd.) through a conventional process, and the yarn is controlled The linear density is 15tex, and the antibacterial yarn-fabric auxiliary yarn is obtained;

[0066] (2) Use the functional yarn and antibacterial yarn in step (1) to weave the mesh jacquard structure on a weft knitting single-sided circular machine (model TF-S3F2 / 4, Fujian Taifan Industrial Co...

Embodiment 3

[0071] A preparation method for perspiration antibacterial cool feeling fabric, comprising the following steps:

[0072] (1) After mixing Coolmax fiber and LYOCELL fiber at a mass ratio of 40:45, weave blended yarn on a small rotor spinning machine (model YHF1618A, Jinzhong Tianyu Textile Machinery Parts Co., Ltd.) by conventional technology to control the yarn line The density is 36tex, and the functional yarn-the main yarn of the fabric is obtained; the bamboo dyer fiber is woven into a yarn on a small rotor spinning machine (model YHF1618A, Jinzhong Tianyu Textile Machinery Parts Co., Ltd.) through a conventional process, and the yarn line is controlled. Density is 15tex, antibacterial yarn-fabric auxiliary yarn;

[0073] (2) The functional yarn and the antibacterial yarn in the step (1) are weaved with a weft knitting single-sided large circular machine (model TF-S3F2 / 4, Fujian Taifan Industrial Co., Ltd.) for plain stitching, In the flat needle plating structure, the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com