A kind of crmn spring steel bloom and its one-fired preparation method

A technology of bloom and spring steel, applied in the field of CrMn spring steel bloom and its one-fired product preparation, can solve the problem of small compression ratio, unfavorable control of microstructure uniformity and compactness, unfavorable decarburization control of spring steel, low heating temperature, etc. problem, to achieve the effect of good depth control of decarburization layer, good density and sufficient fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

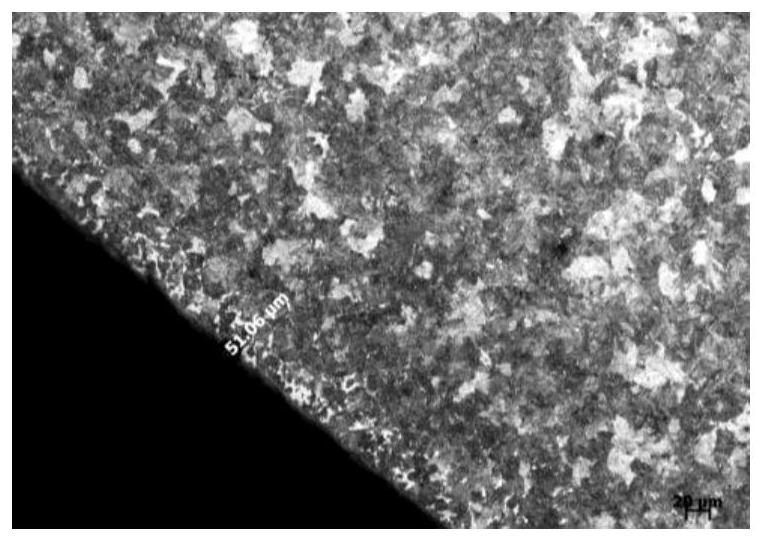

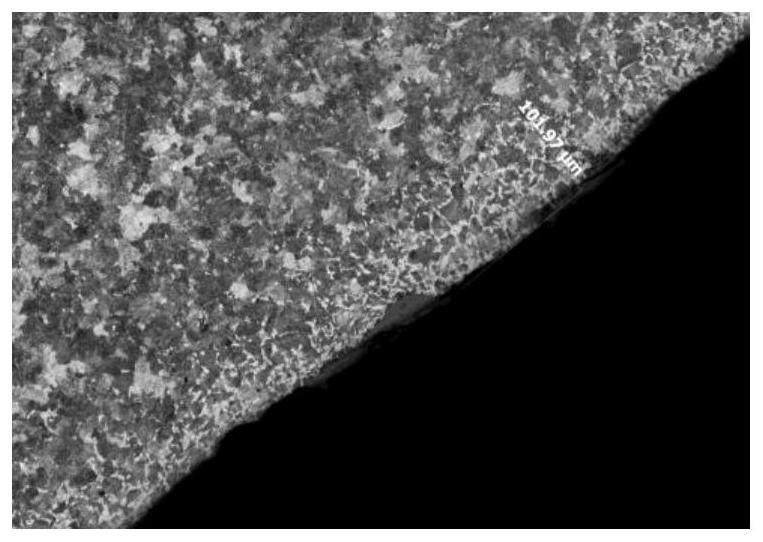

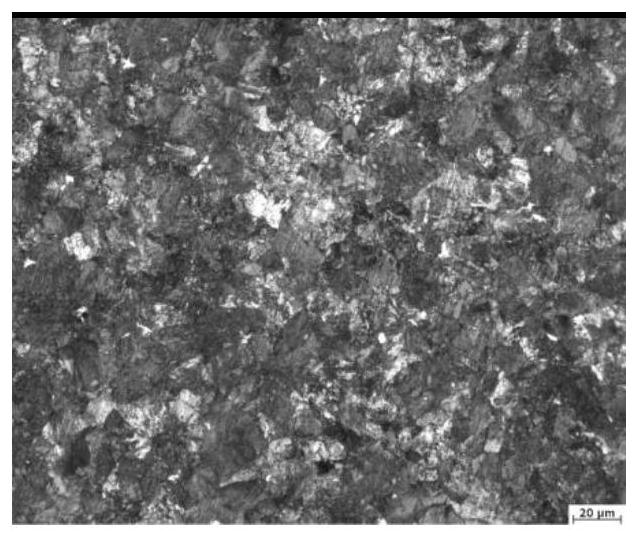

Image

Examples

Embodiment 1

[0025] Using 250mm*300mm spring steel SUP9DZL continuous casting billet, rolled into diameter The standard SUP9D spring round steel process flow is: BOF converter smelting, LF refining furnace, RH treatment, bloom continuous casting, stack cooling, step-by-step continuous heating furnace heating (preheating section temperature: 650-660°C, heating section temperature : 860-890°C, second stage heating temperature: 1010-1020°C, soaking stage one temperature: 1080-1090°C, second soaking stage temperature: 1090-1100°C, final rolling temperature: 800°C total heating time: 187-190min .Gas: blast furnace gas, high-coke mixed gas), 20-pass rolling (10-pass initial rolling + 10-pass intermediate rolling), 4-pass pre-finish rolling, 4-pass KOCKS mill finish rolling, inspection, flaw detection (UT+ET), inspection, packaging, metering, storage.

[0026] The finished material produced by this process has excellent physical and chemical testing performance, good surface condition, and the ...

Embodiment 2

[0038] Using 250mm*300mm spring steel 55Cr3ZL continuous casting billet, rolled into diameter The standard 55Cr3 spring round steel process is: converter smelting, LF refining furnace, RH treatment, bloom continuous casting, stack cooling, step-by-step continuous heating furnace heating (preheating section temperature: 780-800 ℃, heating section temperature: 920-930℃, second heating stage temperature: 1060-1080℃, soaking first stage temperature: 1090-1100℃, soaking second stage temperature: 1110-1120℃, final rolling temperature: 860℃; total heating time: 215-228min .Gas: blast furnace gas, high-coke mixed gas), 20-pass rolling (10-pass initial rolling + 10-pass intermediate rolling), 4-pass pre-finish rolling, 4-pass KOCKS mill finish rolling, inspection, flaw detection (UT+ET), inspection, packaging, metering, storage.

[0039] The finished material produced by this process has excellent physical and chemical testing performance and good surface condition. The compression r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com