A ferritic low-temperature steel forging and its low-temperature cryogenic preparation method

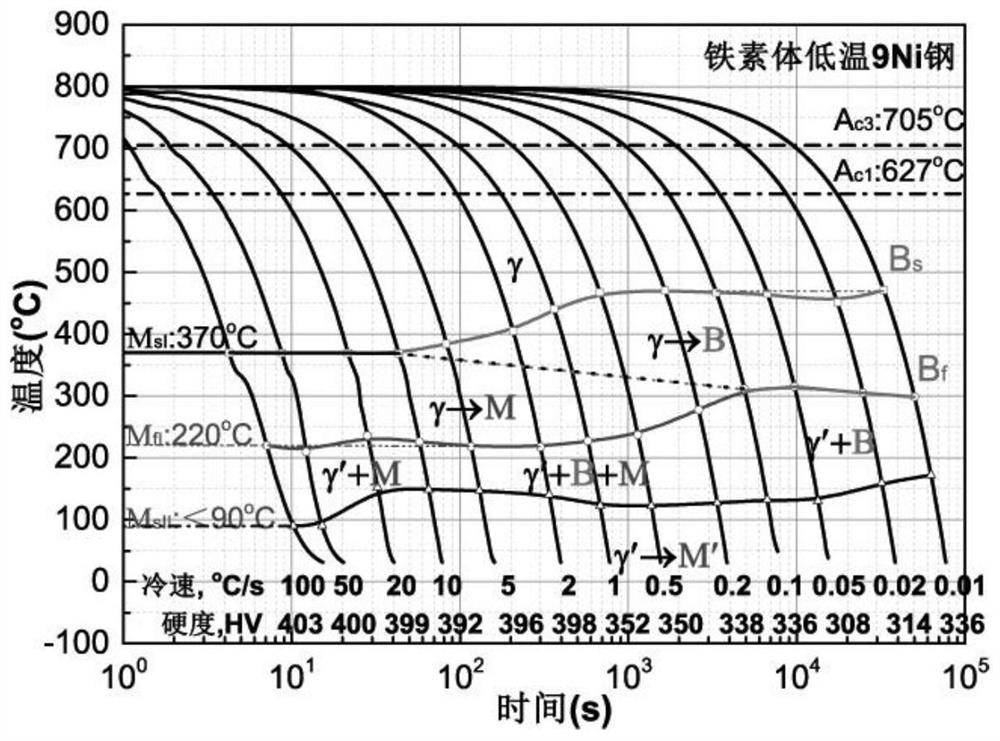

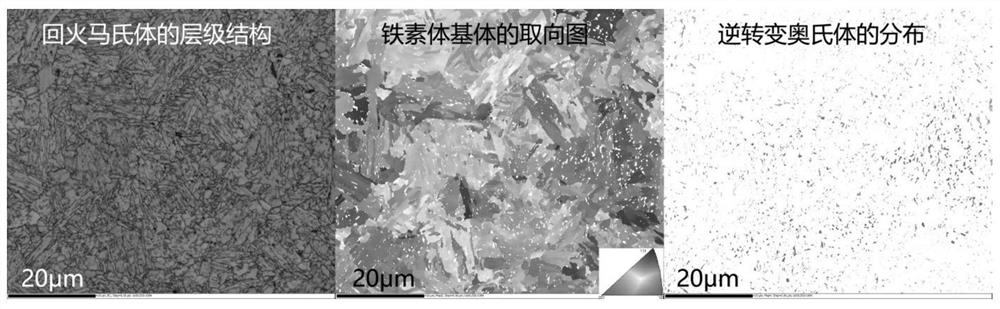

A low-temperature steel and ferrite technology, applied in the field of alloy processing, can solve the problems of high energy consumption in liquid nitrogen cryogenics, uncontrollable continuous cooling, retained austenite or M-A islands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

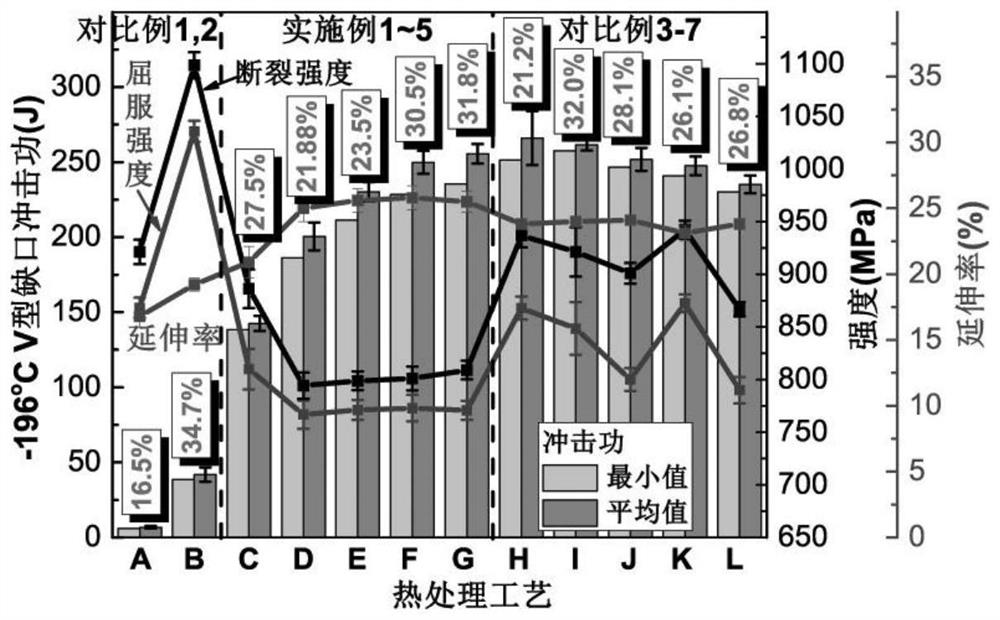

Examples

preparation example Construction

[0024] The invention provides a ferritic low-temperature steel forging and a low-temperature cryogenic preparation method thereof, comprising the following steps:

[0025] (1) performing homogenization annealing after forging the billet to obtain an annealed forging;

[0026] (2) performing quenching and tempering treatment for the first time on the annealed forging obtained in the step (1) successively to obtain a tempered forging;

[0027] (3) subjecting the tempered forgings obtained in the step (2) to sequentially sub-stage cryogenic treatment at -70 to -85°C, -95 to -105°C and -115 to -130°C to obtain cryogenic forgings;

[0028] (4) The cryogenic forging obtained in step (3) is subjected to a second tempering treatment to obtain a ferritic low-temperature steel forging.

[0029] The invention performs homogenization annealing after forging and molding the billet to obtain an annealed forging.

[0030] In the present invention, the starting temperature of the forging is...

Embodiment 1

[0054] In terms of weight percentage, the composition of ferritic low-temperature steel forgings is: 0.03% C, 0.71% Mn, 0.11% Si, 9.35% Ni, 0.80% Cu and the balance iron.

[0055] The preparation method of the ferritic low-temperature steel forging is as follows:

[0056] (1) After soaking the billet at 1110°C, it is forged and formed. The final forging temperature is 750°C, the cumulative compression ratio is 6, air-cooled to room temperature, then heated to 1110°C and kept for 24 hours, homogenized annealed, and air-cooled to room temperature to obtain Annealed forgings;

[0057] (2) Process the annealed forging obtained in step (1), then raise the temperature to 830°C for heat preservation, and then perform quenching to control the cooling rate of the core of the largest section of the forging to >0.05°C / s (or simulated by furnace cooling) , cooled to room temperature;

[0058] (3) The tempered forging obtained in the step (2) is subjected to cryogenic treatment at -80°C,...

Embodiment 2

[0063] In terms of weight percentage, the composition of ferritic low-temperature steel forgings is: 0.03% C, 0.71% Mn, 0.11% Si, 9.35% Ni, 0.80% Cu and the balance iron.

[0064] The preparation method of the ferritic low-temperature steel forging is as follows:

[0065] (1) After soaking the billet at 1110°C, it is forged and formed. The final forging temperature is 750°C, the cumulative compression ratio is 6, air-cooled to room temperature, then heated to 1110°C and kept for 24 hours, homogenized annealed, and air-cooled to room temperature to obtain Annealed forgings;

[0066] (2) Process the annealed forging obtained in step (1), then raise the temperature to 830°C for heat preservation, and then perform quenching to control the cooling rate of the core of the largest section of the forging to >0.05°C / s (or simulated by furnace cooling) , cooled to room temperature, then heated to 625°C for 4 hours for the first tempering, water cooled to room temperature;

[0067](3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com