Treatment method of leachate wastewater of electrolytic aluminum slag field

A treatment method and leachate technology, which is applied in the direction of contaminated groundwater/leachate treatment, water/sewage treatment, special compound water treatment, etc., can solve the problems of inability to deal with pollution indicators, large consumption of inorganic acid, and environmental risks , to achieve the effect of improving denitrification effect, short reaction time and changeable operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

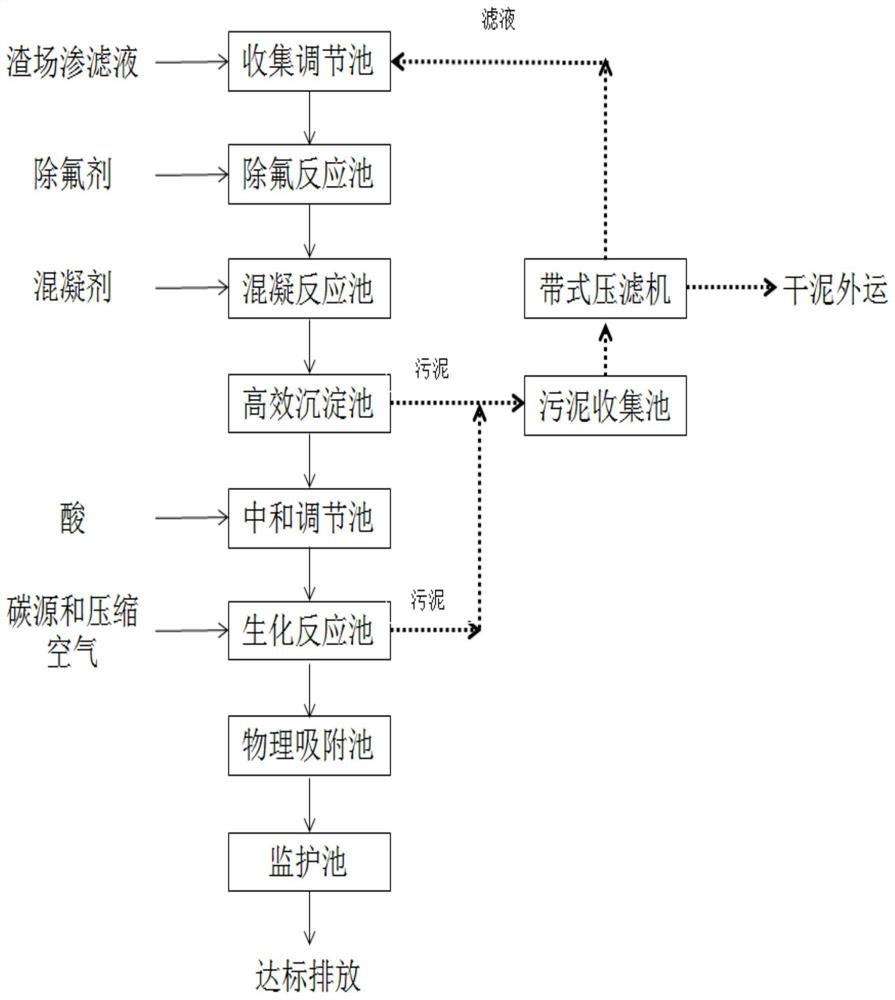

[0033] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0034] like figure 1 As shown, a treatment system for leachate wastewater from an electrolytic aluminum slag field, including a collection and adjustment tank, a defluorination reaction tank, a coagulation reaction tank, a high-efficiency sedimentation tank, a neutralization adjustment tank, a biochemical reaction tank, a physical adsorption tank, and a monitoring tank , sludge collection tank and belt filter press. According to the processing method of a kind of electrolytic aluminum slag field leachate wastewater of the present invention, the concrete steps are as follows:

[0035] (1) The leachate from the electrolytic aluminum slag field enters the collection and adjustment pool through the pump to stabilize the water volume and quality and prevent rapid changes in the load of the treatment system;

[0036] (2) The leachat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com