Graphene composite aerogel film with rivet structure as well as preparation method and application of graphene composite aerogel film

A graphene composite, aerogel technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., to achieve the effects of good mechanical strength, easy operation, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] Another aspect of the embodiments of the present invention also provides a method for preparing a rivet-structured graphene composite airgel film, comprising:

[0080] Using the sol-gel preparation technology assisted by wet-spinning membrane, a rivet-structured graphene composite hydrogel film was prepared;

[0081] Carry out drying treatment (such as supercritical fluid drying and / or freeze-drying treatment) to described rivet structure graphene composite hydrogel film, while keeping the gel network from being destroyed, remove the solvent molecule in the gel, obtain rivet Structural graphene composite airgel films.

[0082] In some embodiments, the preparation method of the rivet structure graphene composite airgel film specifically includes:

[0083] (1) providing a coagulation bath comprising reducing ferrous metal ions;

[0084] (2) Using wet spinning method, the graphene oxide liquid crystal is injected into the coagulation bath, and the reducing ferrous metal ...

Embodiment 1

[0131] (a) The graphene oxide liquid crystal of 5mg / ml is injected into the coagulation bath of 0.01wt% ferrous sulfate solution simultaneously with the injection speed of 0.01ml / min through wet-spun film needle (width is 5mm), obtains continuous graphene Hydrogel film.

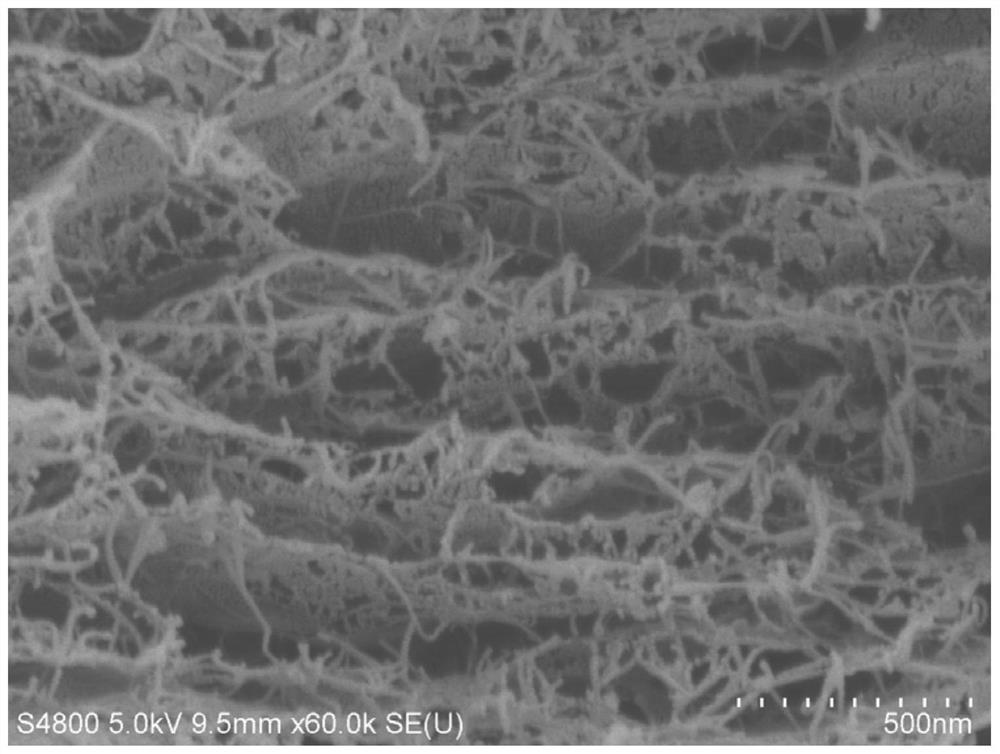

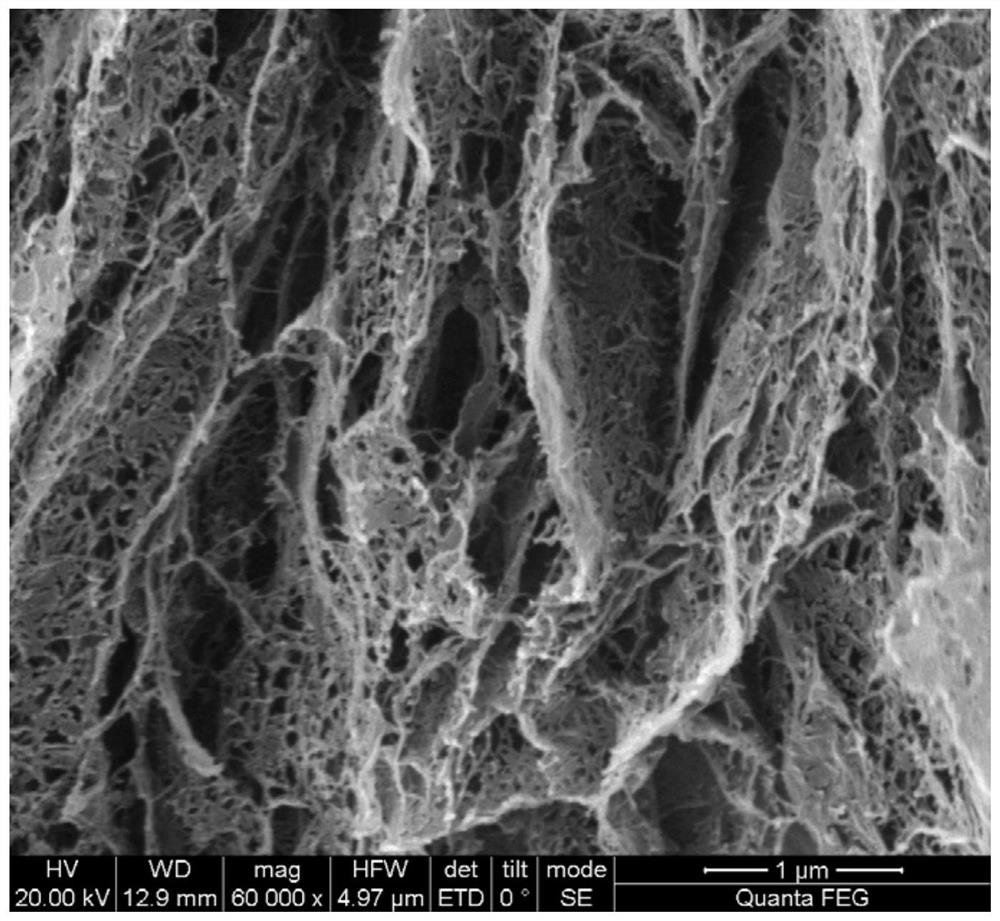

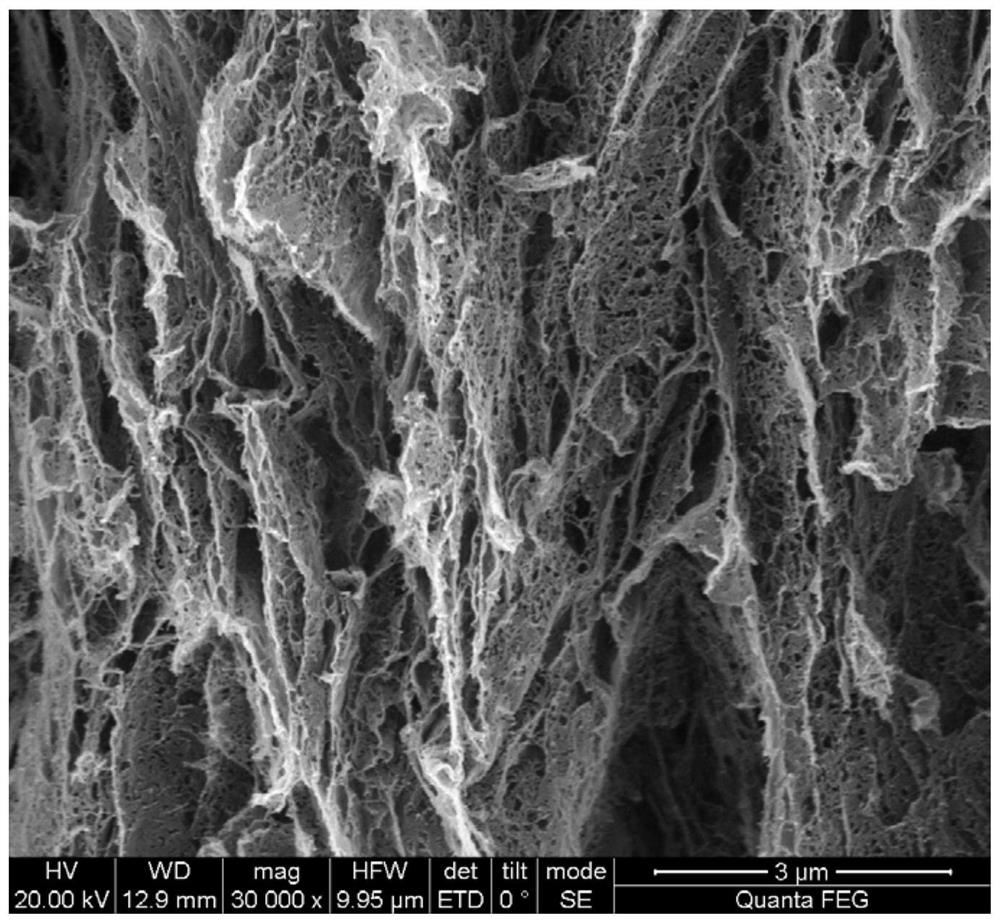

[0132] (b) immerse the graphene hydrogel film in the step (a) in the coagulation bath solution, utilize the ferrous ion in the coagulation bath to reduce the graphene oxide, leave it at 20 DEG C for 6h, generate iron oxyhydroxide nanofibers, and then After waiting for chemical sol-gel aging, the graphene composite hydrogel film with rivet structure was obtained.

[0133] (c) the rivet structure graphene composite hydrogel film in step (b) is replaced ten times through ethanol solvent, the time of each replacement is 3h, and the volume ratio of ethanol and rivet structure graphene composite hydrogel film is 5: 1. Afterwards, at 30°C, supercritically dry for 24 hours to obtain a rivet-structured graphene compo...

Embodiment 2

[0139] (a) The graphene oxide liquid crystal of 10mg / ml is injected into the coagulation bath of 0.1wt% ferrous chloride solution simultaneously with the injection speed of 0.1ml / min through wet-spun film needle (width is 8mm), obtains continuous graphite Alkene hydrogel films.

[0140] (b) immerse the graphene hydrogel film in the step (a) in the coagulation bath solution, utilize the ferrous ion in the coagulation bath to reduce the graphene oxide, leave it at 30 DEG C for 8h, generate iron oxyhydroxide nanofibers, and then After waiting for chemical sol-gel aging, the graphene composite hydrogel film with rivet structure was obtained.

[0141] (c) the rivet structure graphene composite hydrogel film in step (b) is replaced ten times through ethanol solvent, the time of each replacement is 5h, and the volume ratio of ethanol and rivet structure graphene composite hydrogel film is 8: 1. After that, supercritically dry at 44°C for 24 hours to obtain a rivet-structured graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com