Stator assembly with high power generation performance

A stator assembly and performance technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of poor stator power generation performance and low winding process efficiency, so as to improve power generation performance, improve slot full rate, and improve power generation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

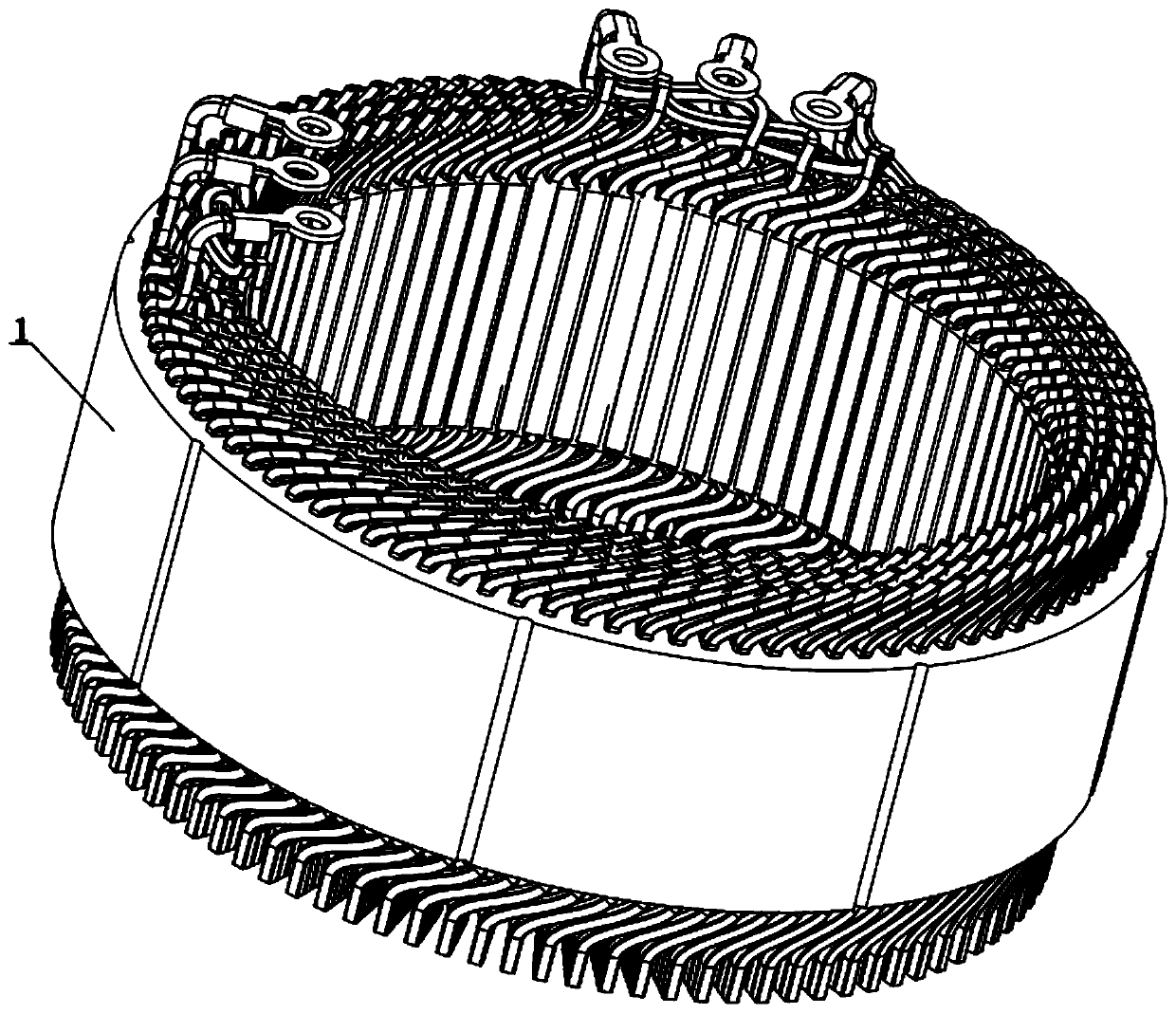

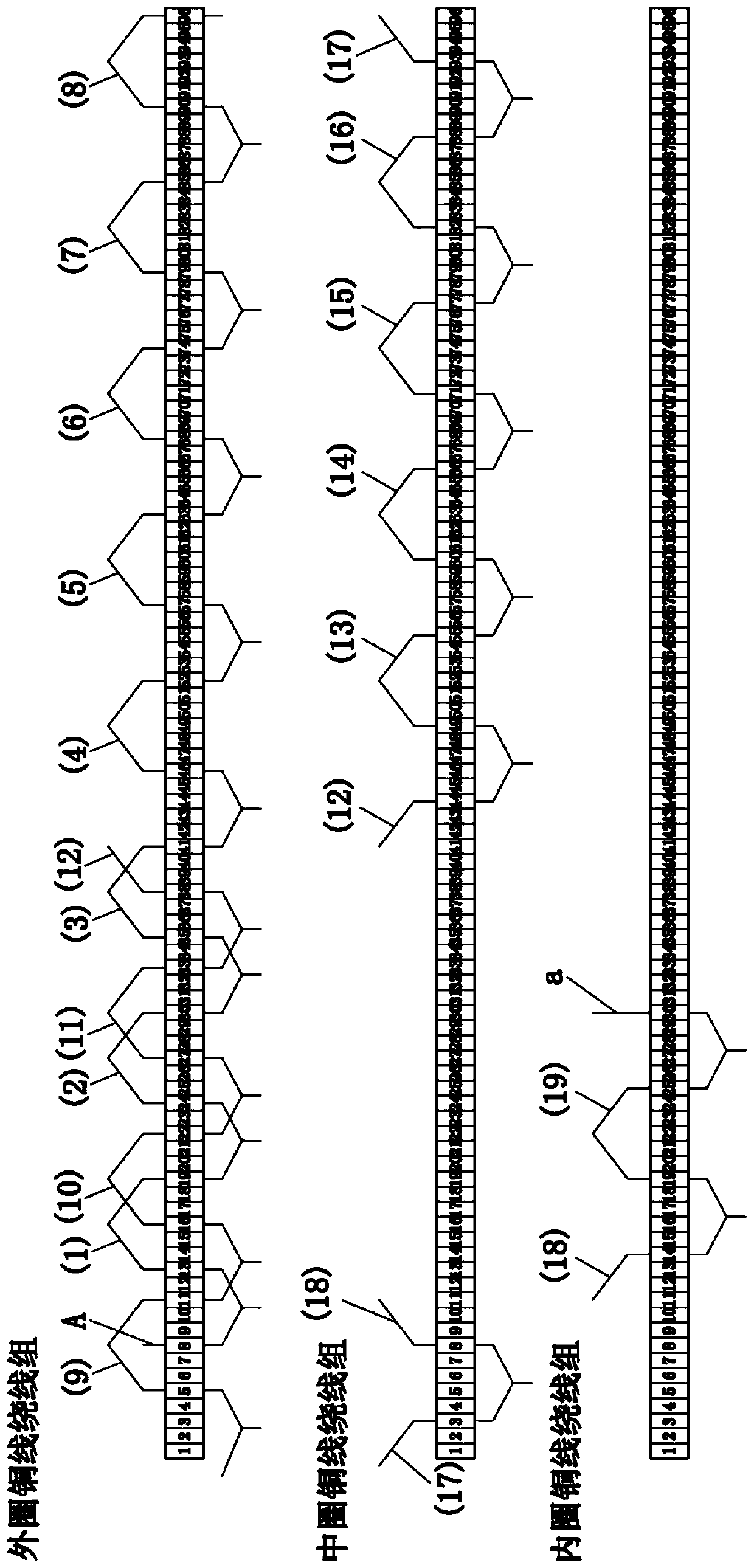

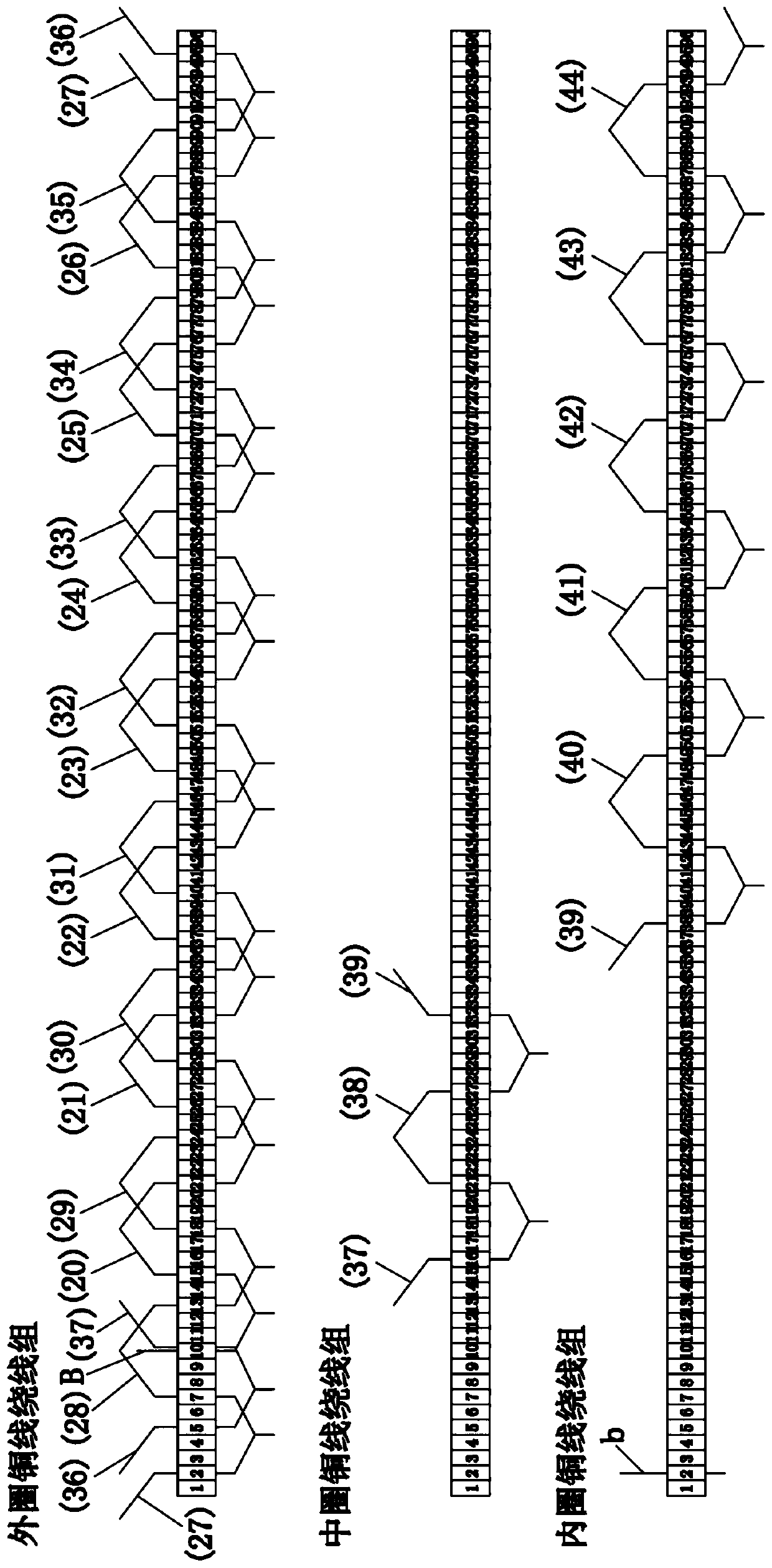

[0026] refer to figure 1 , Figure 15 and Figure 16 . A stator assembly with high power generation performance, including a stator core 1, a ring of the stator core 1 is provided with several wire insertion slots 2, each wire insertion slot 2 has three layers of outer, middle, and inner wire insertion positions, said A three-layer winding group is inserted in several insertion slots, and the three-layer winding group is composed of twelve sets of copper wire winding groups connected from 1 to 12, and each group of copper wire winding groups is wound by an outer ring copper wire. Group I, copper wire winding group II in the middle circle and copper wire winding group III in the inner circle, the copper wire winding group I in the outer circle, copper wire winding group II in the middle circle and copper wire winding group III in the inner circle A number of bent flat copper wires 3 in different quantities are respectively used. The flat copper wires of the outer ring copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com