Elevator Safety Devices and Elevators

A technology of elevator safety device and wedge, which is used in transportation and packaging, lifting equipment in mines, elevators, etc., can solve problems such as heavy elevator design, accidental injury, and difficulty in safety device design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

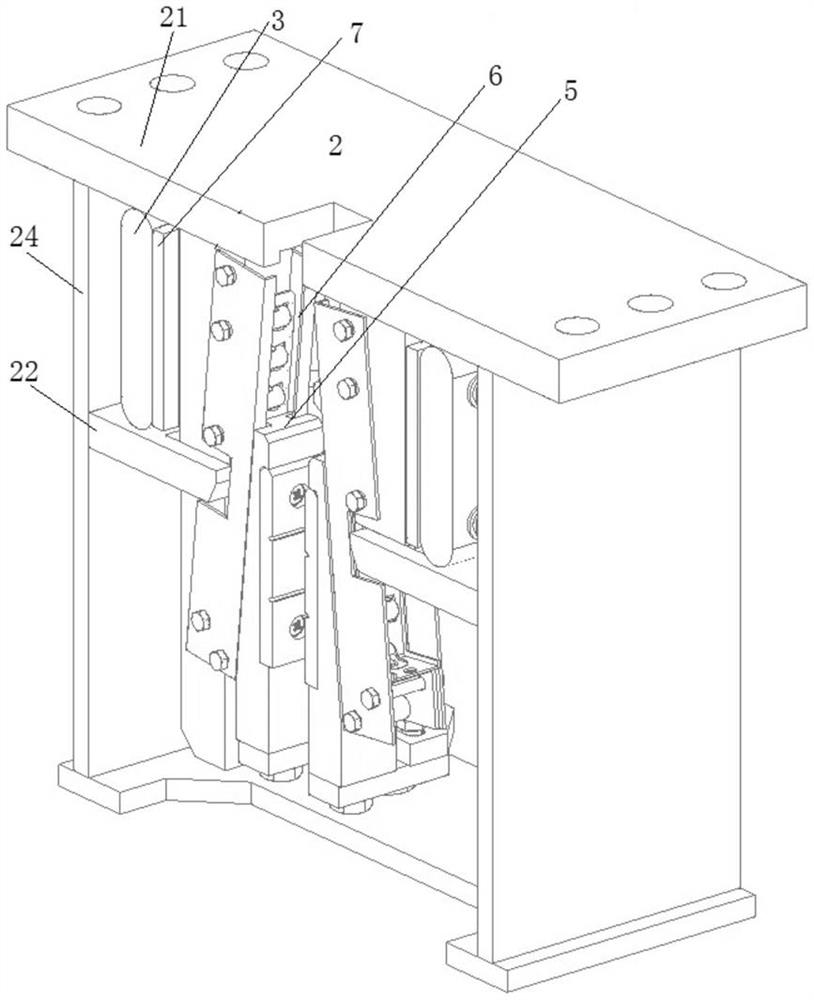

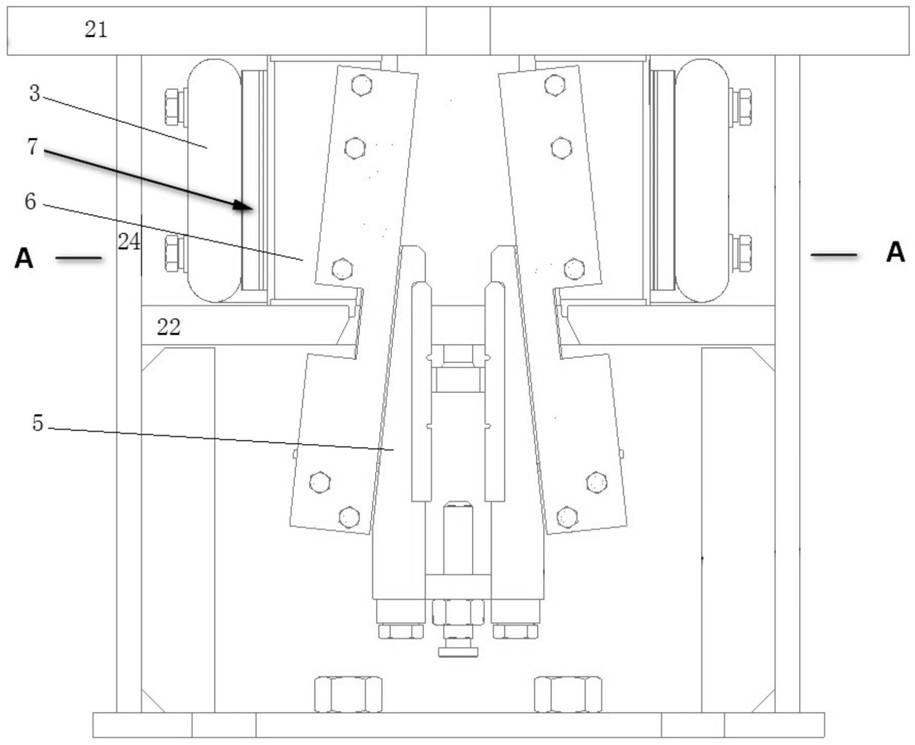

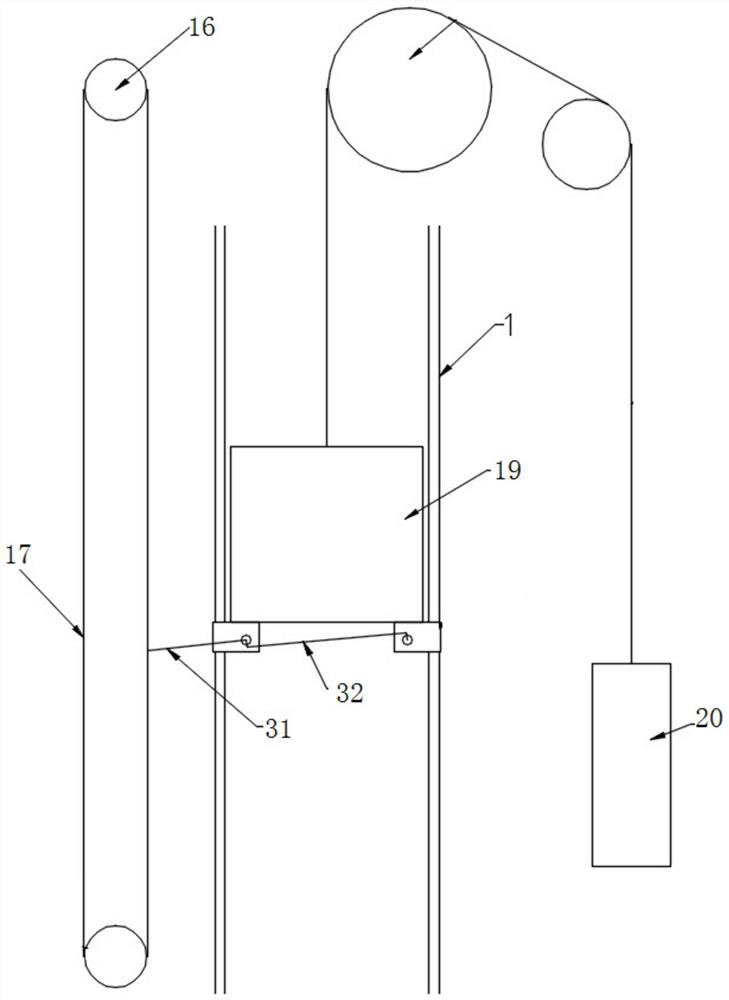

[0064] Such as Figure 1 to Figure 7 As shown, the elevator safety device includes a frame 2, a brake body 5, a guide wedge 6, a first elastic body 3, an adjustment body 7, an adjustment wedge 11, a rear guide 4, a connecting body 14, and an adjustment bolt 13 ;

[0065] The frame 2 is used to be installed on the lifting body guided by the guide rail 1 arranged in the lifting passage, and the guide rail 1 is located on the front side of the frame 2;

[0066] The frame 2 includes an upper plate 21, a middle plate 22, a side plate 24 and a fixing seat 25;

[0067] The upper end of the side plate 24 is fixedly connected to the upper plate 21;

[0068] The end of the middle plate 22 is fixedly connected to the side plate 24;

[0069] The lower side of the front part of the upper plate 21 and the upper side of the front part of the middle plate 22 are correspondingly provided with grooves 26 in the left and right directions;

[0070] The fixing seat 25 is vertically fixed betwe...

Embodiment 2

[0097] Based on the elevator safety device of Embodiment 1, such as Image 6As shown, when the brake body 5 rises to a predetermined position, the contact point between the guide wedge 6 and the adjustment body 7 is located at the junction of the vertical high section 72 and the vertical transition section 73, and the first elastic body 3 is The distance of the deformation to the far side of the guide rail is D, the front and rear compression distance of the second elastic body 9 relative to the initial state is B, and a gap with a front and rear width of B is formed between the front side of the rear guide 4 and the fixed seat 25.

Embodiment 3

[0099] Based on the elevator safety device of the second embodiment, the height difference A between the vertical high section 72 and the vertical low section 74 of the adjustment body 7 is smaller than D.

[0100] Preferably, the vertical transition section 73 has a certain inclination angle, and the included angle with the vertical high section 72 and the vertical low section 74 is between 10° and 80°.

[0101] In the elevator safety device of Embodiment 3, the braking body 5 continues to rise to drive the connecting body 14 and the adjusting bolt 13 to rise together, push the support rod 15 to rise, and push the rear guide 4 and the first elastic body 3 backward through the action of the slope move, so that the adjustment body 7 moves together, the contact point between the guide wedge 6 and the adjustment body 7 changes from the vertical high section 72 to the vertical transition section 73, and the vertical transition section 73 has a certain inclination angle, due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com