Controllable chiral structure based on GST phase change material temperature control and control method

A technology of chiral structure and temperature control, applied in nonlinear optics, instruments, optics, etc., can solve problems such as inability to reconfigure, reduce practical performance, etc., achieve powerful functions, good circular dichroism, and large working wavelength range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

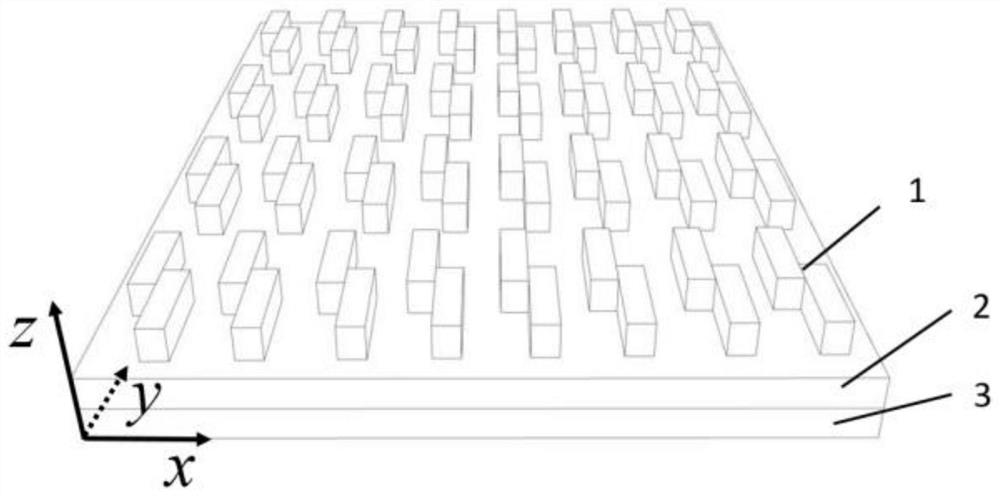

[0033] Such as figure 1 As shown, a controllable chiral structure based on the temperature control of GST phase change materials, including a gold substrate 3, a silicon dioxide film 2 on the surface of the gold substrate 3, and chiral GST prepared on the surface of the silicon dioxide film 2 array1. Wherein, the unit of the chiral GST array 1 is composed of two cuboid GSTs, and the two cuboids GST overlap in the longitudinal direction, that is, the unit is a mirror-image asymmetric GST structure.

[0034] The thickness of the rectangular parallelepiped GST is 140 nanometers, the length is between 565 nanometers and 915 nanometers, and the width is 160 nanometers. The longitudinal overlapping length of two rectangular parallelepiped GSTs is 50 nanometers. The unit lateral period of the chiral GST array 1 is 400 nanometers, and the vertical period is between 1.1 μm and 1.8 μm. The silicon dioxide thin film 2 has a thickness of 120 nanometers, and the gold substrate 3 has a th...

Embodiment 2

[0041] Such as Figure 4 As shown, a controllable chiral structure based on the temperature control of GST phase change materials, including a gold substrate 3, a silicon dioxide film 2 located on the surface of the gold substrate 3, and a mirror image chirality is prepared on the surface of the silicon dioxide film 2 GST array4. Such as Figure 4 As shown in the middle dotted line box, the unit of the mirror-image chiral GST array 4 is composed of a pair of mirror-image GST chiral structures, each GST chiral structure is composed of two cuboid GSTs, and the two cuboid GSTs overlap in the longitudinal direction.

[0042] The thickness of the rectangular parallelepiped GST is 140 nanometers, the length is between 565 nanometers and 915 nanometers, and the width is 160 nanometers. The longitudinal overlapping length of two rectangular parallelepiped GSTs is 50 nanometers. The unit lateral period of the mirror-image chiral GST array 4 is 400 nanometers, and the vertical period ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com