Air door adjusting mechanism used for gas cooking appliance

A damper adjustment and gas cooker technology, which is applied in the field of household kitchen utensils, can solve the problems of large air ejection resistance, insufficient combustion, nozzle clogging, etc., and achieve the goals of improving combustion efficiency and thermal efficiency, improving insufficient ejection, and reducing smoke emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

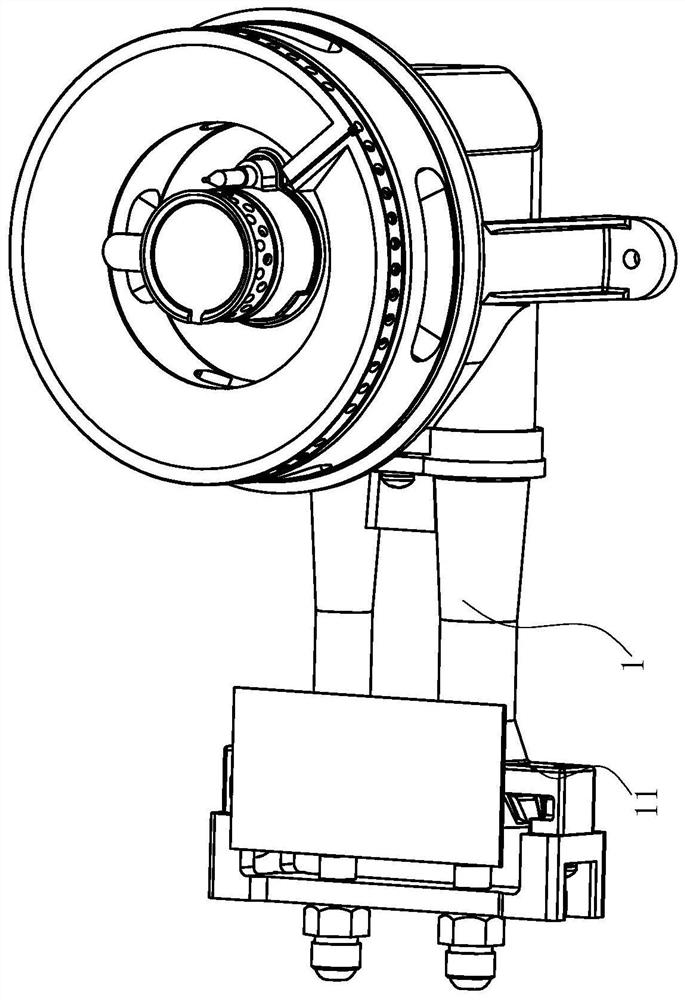

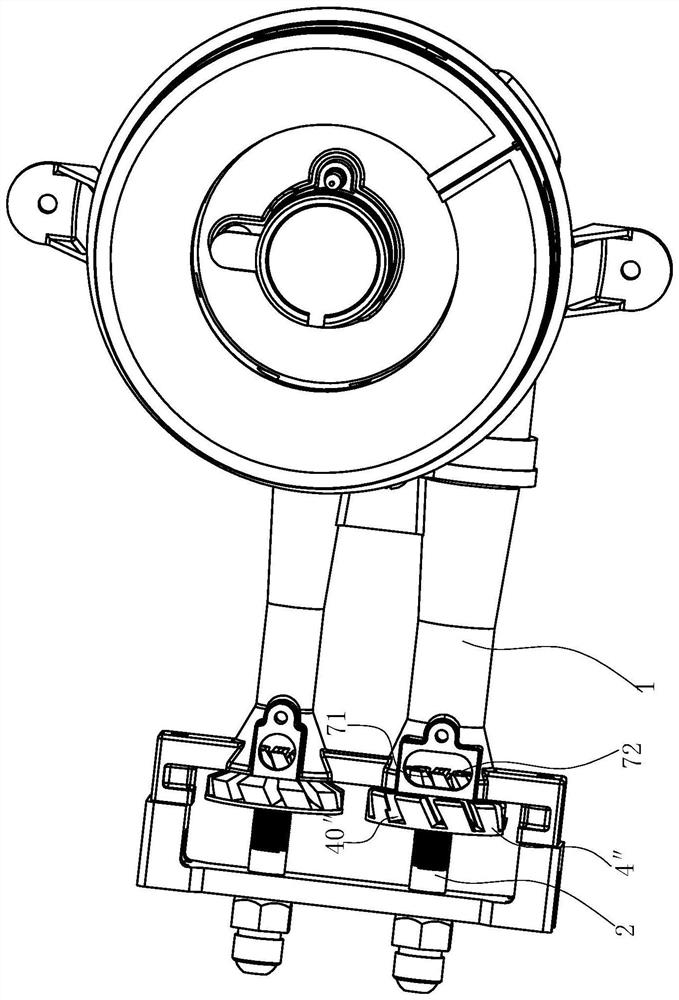

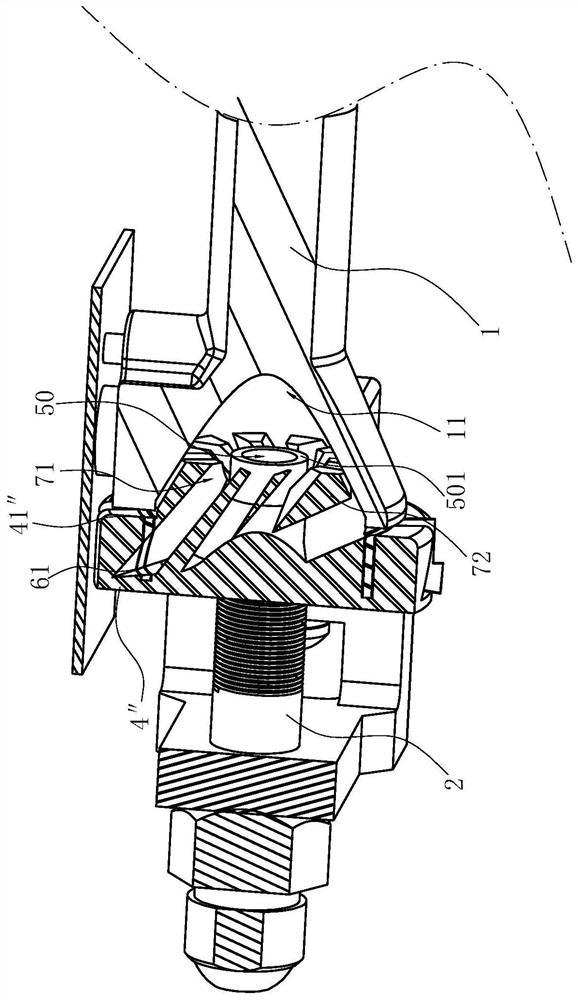

[0046] Such as Figure 1-10 As shown, it is the best embodiment of the present invention. In this embodiment, the damper adjustment mechanism for the gas cooker includes an injection pipe 1, a nozzle seat 2 and a nozzle 3 installed on the nozzle seat 2. The nozzle of the nozzle 3 faces The air inlet end 11 of the ejection pipe 1 also includes an air guide member installed on the nozzle seat 2, the air guide member includes a body, the center of the body has a central hole 50 for the nozzle 3 to extend into, and the body also has at least Two guide parts arranged around the central hole 50, the interval between adjacent guide parts forms a primary air channel 40 "for guiding the primary air. Due to the primary air channel 40", the air guide can be simply The central hole 50 is sleeved outside the nozzle 3 or the nozzle seat 2, for example, the two are screwed together, so that the air guide can be positioned and the position between the air guide and the nozzle 3 can be adjuste...

Embodiment 2

[0051] Different from the structure of Embodiment 1, the structure of the air guide can also be as follows: the air guide includes a plate body 5', the central hole 50 is arranged at the center of the plate body 5', and the guide part is arranged on the plate body 5'. Peripheral locations other than the central hole 50 . Wherein, the guide part is a cantilever-type raised strip 4', and the adjacent cantilever-shaped raised strip 4' forms a primary air passage 40', and the primary air passage 40' includes an air outlet end 401' adjacent to the central hole 50 and an air outlet end far away from the center. The inlet end 402' of the hole 50, the diameter of the inlet end 402' is larger than the diameter of the outlet end 401', so that the primary air in the primary air passage can be accelerated after it enters, and the swing arm type convex strip 4' includes a The outer end 41' of 50 and the inner end 42' adjacent to the central hole 50, the width of the outer end 41' of the ca...

Embodiment 3

[0053] Different from the adjusting part 6 with the plate body 5' in Embodiments 1 and 2, the air guiding part in this embodiment is in the shape of a circular platform 5. In order to enhance the ability of the air guiding part to guide the primary air, the air guiding part is gradually moving toward the air guiding part. The air inlet end 11 of the jet tube 1 is in the shape of a circular platform 5, and the guide part is a rib 4, which is arranged on the side wall of the air guide. The interval between adjacent guide parts forms a primary air for guiding the primary air. The channel 40 , the primary air channel 40 includes an air outlet 401 adjacent to the central hole 50 and an inlet 402 away from the central hole 50 , the diameter of the inlet 402 is larger than that of the outlet 401 . The rib 4 includes an outer end 41 far away from the air inlet end 11 of the ejector tube 1, and an inner end 42 adjacent to the air inlet end 11 of the ejector tube 1. The rib 4 gradually p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com