Composite coiled tubing cable horizontal well water outlet section testing system and method

A testing system and coiled tubing technology, which is applied to the cable installation, measurement, drilling pipe and other directions in the ground conduit, which can solve the problems of affecting the sampling effect, long sampling period and high operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

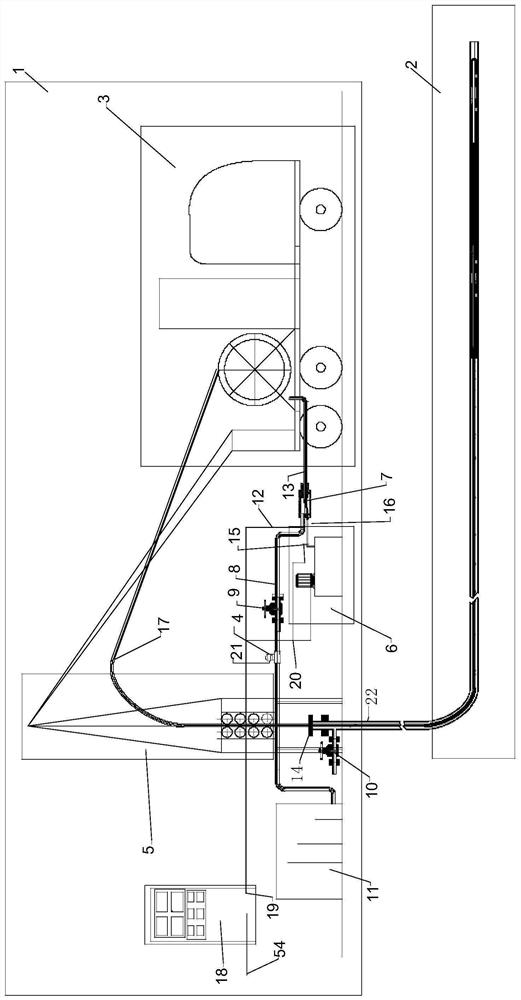

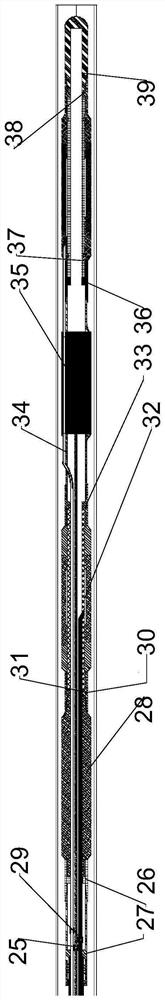

[0079] Such as figure 1 with figure 2 As shown, the composite continuous umbilical cable horizontal well water section test system of the present invention is composed of ground equipment 1 and downhole tool 2;

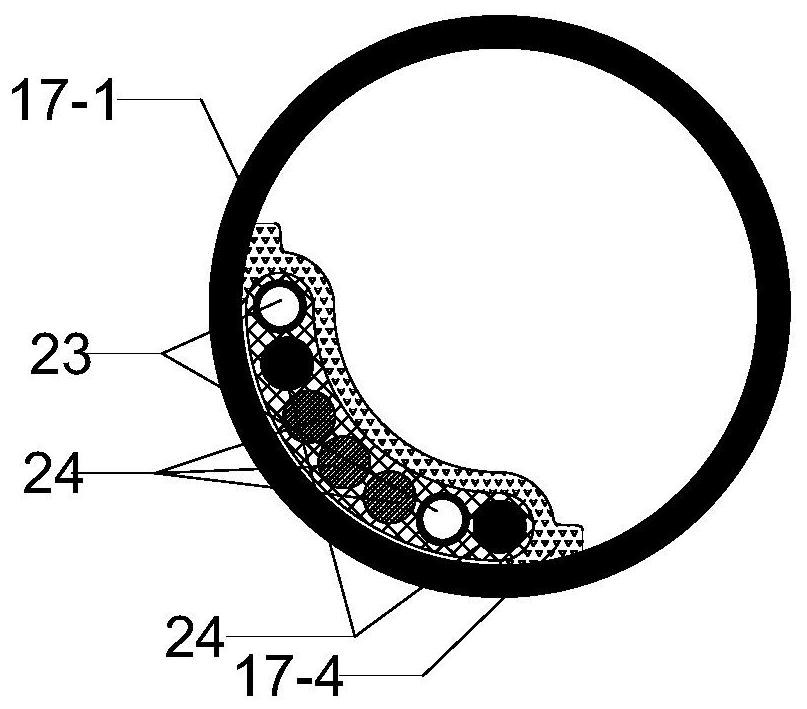

[0080] The ground equipment 1 includes a coiled tubing operation vehicle 3, a production fluid storage test tank 11, a surface hydraulic station 6, a composite umbilical cable ground separator 7, and a ground control and monitoring system 18; the coiled tubing operation vehicle 3 is used to convert the composite coiled tubing The cable 17 is put into the downhole tool 2, and the composite umbilical cable 13 output by the coiled tubing vehicle is connected with the composite umbilical cable ground separator 7; The composite umbilical ground separator 7 is connected to the production fluid storage test tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com