Construction method of cover-excavation top-down permanent steel pipe column

A technology of cover and excavation reverse work and construction method, which is applied in basic structure engineering, basic structure test, sheet pile wall and other directions, can solve the problem that there is no complete, mature and safe construction method and positioning accuracy for the installation and positioning of large diameter steel pipe columns Unable to guarantee and other problems, to achieve the effect of ensuring project quality and safety performance, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

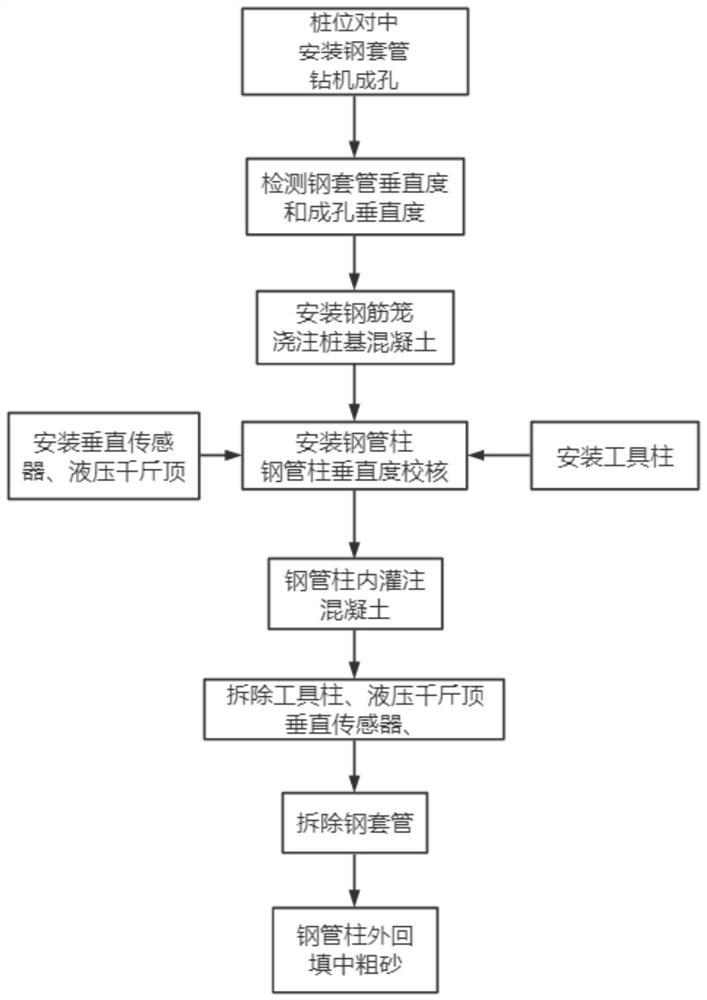

[0025] A construction method for cover-excavation and upside-down permanent steel pipe columns, please refer to figure 1 , including the following steps:

[0026] S1. Pile position is centered, steel casing is installed, and the drilling machine is drilled: use a full casing full-rotary drilling rig to rotate and press the steel casing into the pile location, and perform drilling operations at the same time, so that the steel casing is ahead of the drilling depth and inspected. Verticality of steel casing and hole verticality;

[0027] Before installing the steel casing, the construction site is leveled, and the central line of the pile position and the positioning pile are released by a total station, and then led out to the control pile. In this embodiment, the control pile is made of Φ12 steel bars, and its Drive into the ground at least 30cm below the ground, check the pile position and the pile center repeatedly, and after confirming that it is correct, hoist the base of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com