A method for efficient separation of straw components using a new type of deep eutectic solvent

A low eutectic solvent, a new type of technology, applied in the use of microorganism/enzyme cellulose treatment, papermaking, textiles and papermaking, etc., can solve the problems of small molecular weight of lignin, narrow utilization window, destruction, etc., to achieve simple synthesis and high efficiency The effect of removing and improving the efficiency of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

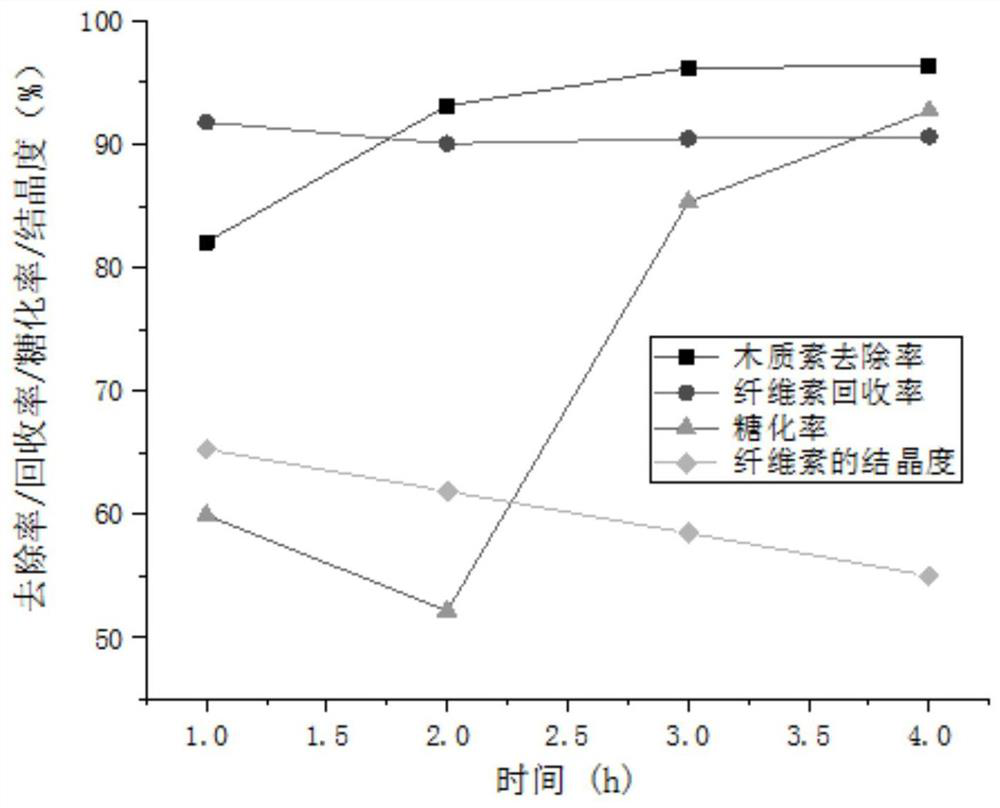

[0040]The method of highly separating straw components using new low-molten solvents, including the following steps:

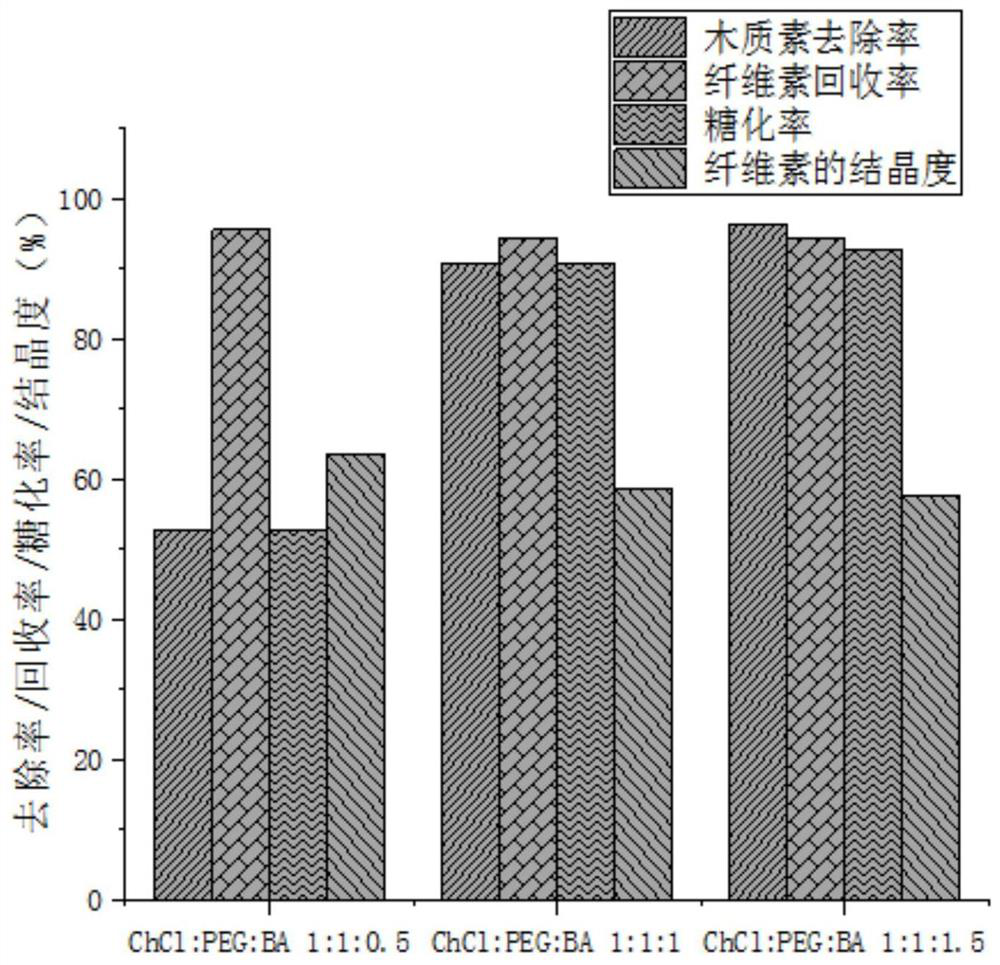

[0041] (1) Synthesis of new low-molten solvent: Choline, polyethylene glycol-200 and boric acid are synthesized according to Table 2, which is directly used without purification;

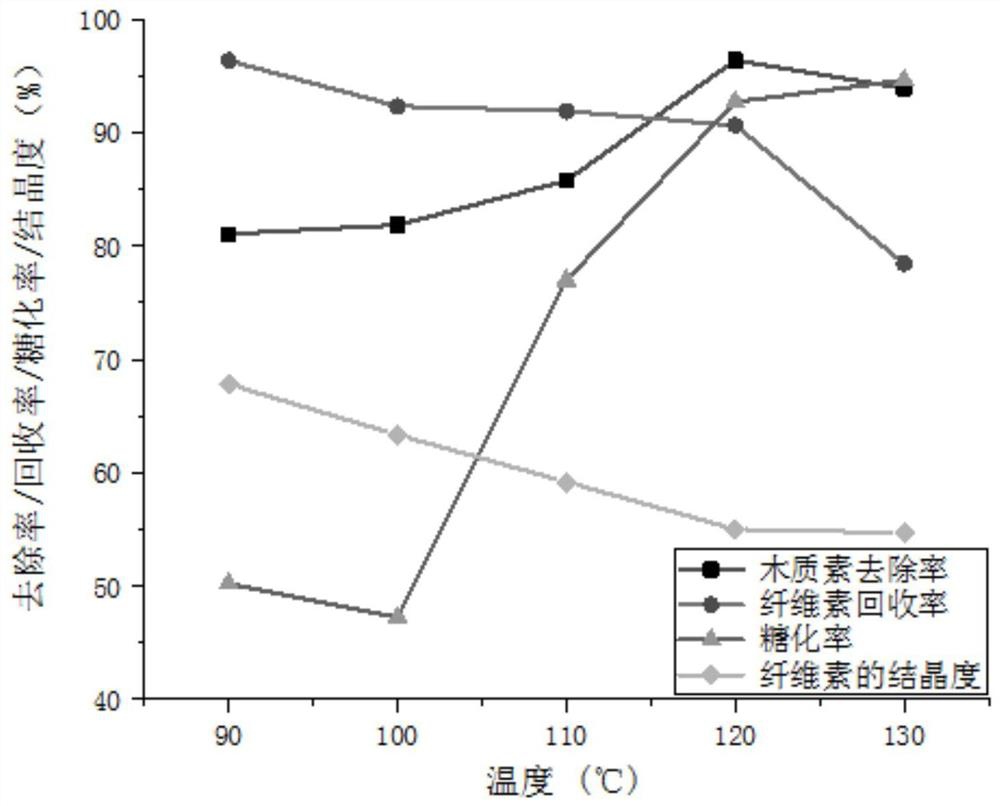

[0042] (2) Straw primary treatment: First, the straw and deionized water are mixed according to the solid-liquid ratio of 1:15, and the reaction is 0.5 h at 120 ° C; then the solid-liquid separation is obtained to obtain the filtrate I and the filter residue I, and the filter residue I is used Ion water was washed 2 ~ 3 times, and the straw residue treated by one level was obtained;

[0043] (3) Extraction of hemicellulose: ethanol is added to the filtrate I obtained from step (2), wherein the volume ratio of ethanol and the filtrate I is 5: 1; after standing precipitation, the desirated solid is washed with ethanol, centrifuged. That is, half cellulose; filtered the obtained ethanol fi...

Embodiment 2

[0054] The method of highly separating straw components using new low-molten solvents, including the following steps:

[0055] (1) Synthesis of a new type of low-molten solvent: mixing choline, polyethylene glycol-200 and boric acid in accordance with molar ratio 1: 1: 1.5, reacting at 80 ° C for 1 h, i.e., a new low-molten solvent No need to purify directly;

[0056] (2) Straw primary treatment: First, the straw and deionized water are mixed according to the solid-liquid ratio of 1:15, and the reaction is 0.5 h at 120 ° C; then the solid-liquid separation is obtained to obtain the filtrate I and the filter residue I, and the filter residue I is used Ion water was washed 2 ~ 3 times, and the straw residue treated by one level was obtained;

[0057] (3) Extraction of hemicellulose: ethanol is added to the filtrate I obtained from step (2), wherein the volume ratio of ethanol and the filtrate I is 5: 1; after standing precipitation, the desirated solid is washed with ethanol, centri...

Embodiment 3

[0065] The method of highly separating straw components using new low-molten solvents, including the following steps:

[0066] (1) Synthesis of a new type of low-molten solvent: mixing choline, polyethylene glycol-200 and boric acid in accordance with molar ratio 1: 1: 1.5, reacting at 80 ° C for 1 h, i.e., a new low-molten solvent No need to purify directly;

[0067] (2) Straw primary treatment: First, the straw and deionized water are mixed according to the solid-liquid ratio of 1:15, and the reaction is 0.5 h at 120 ° C; then the solid-liquid separation is obtained to obtain the filtrate I and the filter residue I, and the filter residue I is used Ion water was washed 2 ~ 3 times, and the straw residue treated by one level was obtained;

[0068] (3) Extraction of hemicellulose: ethanol is added to the filtrate I obtained from step (2), wherein the volume ratio of ethanol and the filtrate I is 5: 1; after standing precipitation, the desirated solid is washed with ethanol, centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com