Traction device for multi-wire-diameter array cables

A traction device and array cable technology, which is applied in the field of multi-diameter array cable traction devices, can solve the problems of loss of traction force, insufficient redundancy, and non-metallic materials that are prone to aging and brittle fracture, so as to slow down the aging speed and improve traction work efficiency , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

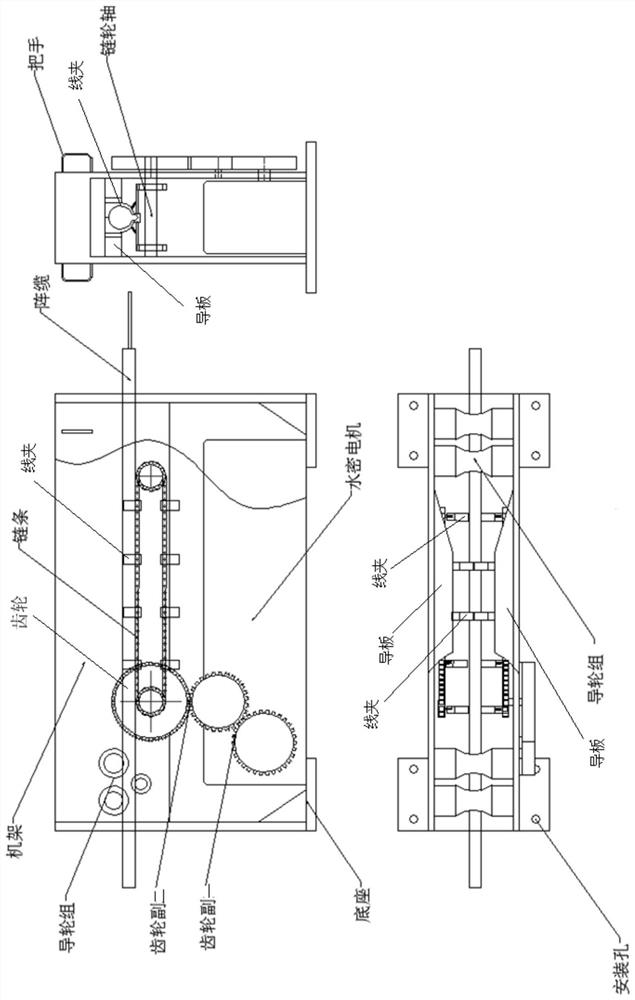

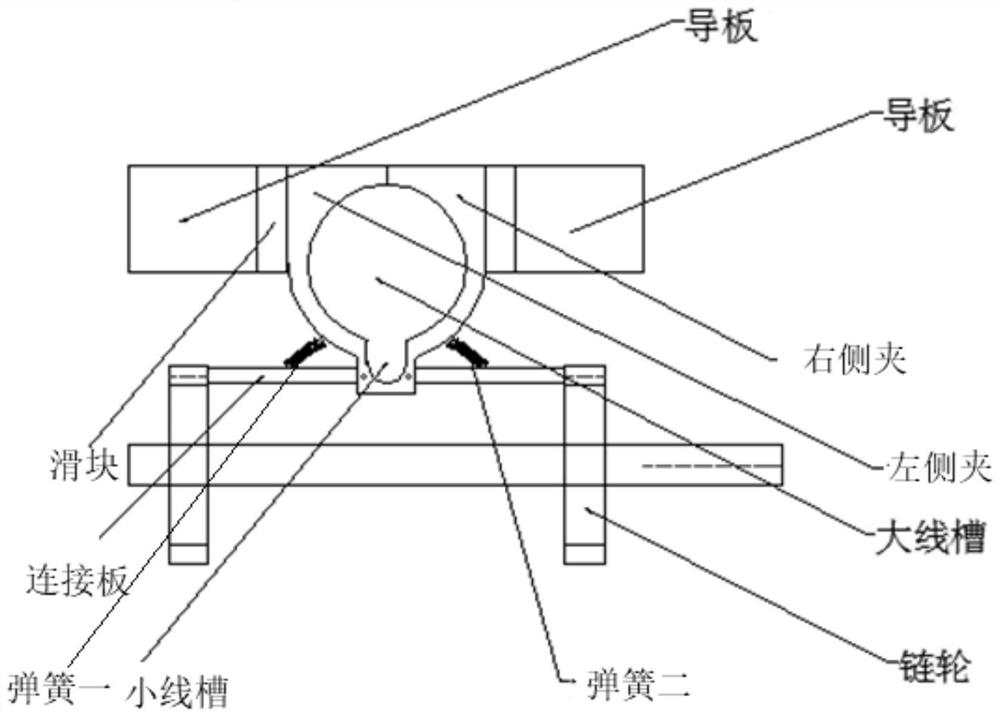

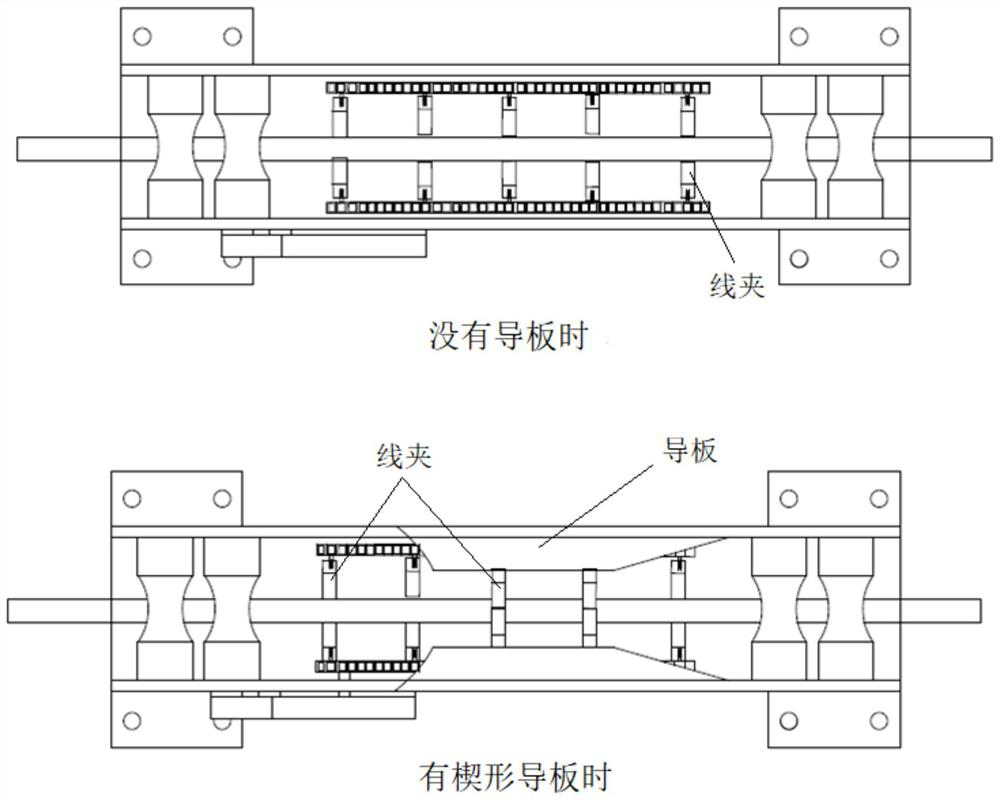

[0031] An embodiment of the present invention is a figure 1 The shown double-diameter array cable pulling device includes a base, a frame, a driving device, a transmission device, a wire clamp, and a guide plate. The driving device includes a watertight motor assembly including a reducer, gear pairs 1 and 2 gear pairs that are meshed in sequence. 2. Gears. The transmission device includes two sets of sprockets and chains. Each set of sprockets includes two parallel and opposite sprockets. The chain is located between the two parallel and opposite sprockets and is driven by the sprockets. The wheel and the gear are connected through the sprocket shaft, which is the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com