Printing equipment capable of conveniently machining PE bottle caps of different sizes

A technology for printing equipment and bottle caps, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of time-consuming and laborious, inconvenient to change the printing style, and inconvenient to adjust the clamping width, etc., and achieve the effect of avoiding repeated replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

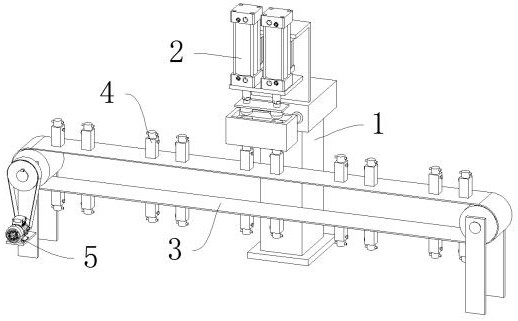

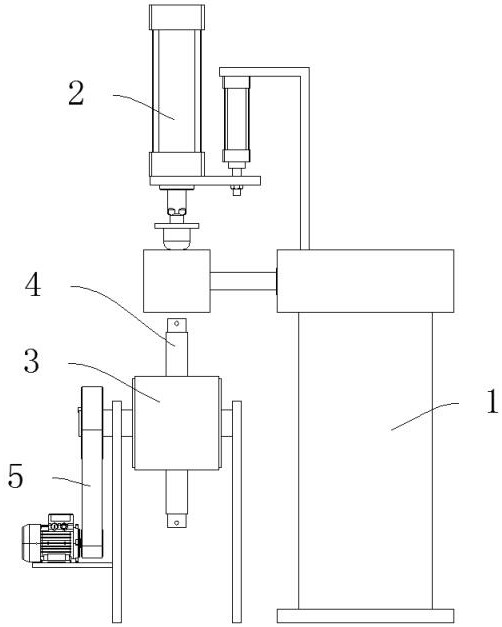

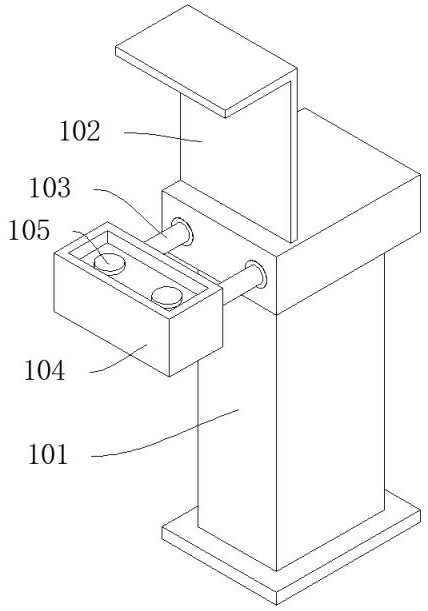

[0044] like Figure 1-Figure 7As shown, a printing equipment for processing PE bottle caps of different sizes, including a table device 1 for supporting printing, a pad printing device 2 for lifting printing is installed in front of the table device 1, and a pad printing device 2 is installed below the pad printing device 2 There is a conveying device 3 for conveying PE bottle caps, a number of positioning devices 4 for fixing PE bottle caps are evenly distributed on the conveying device 3, and a driving device 5 for providing power is installed in front of the conveying device 3; the table device 1 includes A support platform 101, a first support plate 102 is arranged on the support platform 101, two first cylinders 103 are symmetrically installed in the support platform 101, an ink cartridge 104 is installed in front of the first cylinder 103, and a pad printing plate 105 is installed in the ink cartridge 104 The pad printing device 2 includes 2 second cylinders 201 that are...

Embodiment 2

[0047] like Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the driving device 5 includes a motor 501, a pinion 505 is installed behind the motor 501, a bull gear 506 is arranged above the pinion 505, and the pinion 505 and the bull gear 506 are meshed for transmission; The motor 501 is connected with the motor base 302 by bolts, the motor 501 is connected with the pinion 505 by a flat key, and the bull gear 506 is connected with the transmission shaft 303 by a flat key.

[0048] Working principle: By rotating the support column 403 to lift up and down in the support block 401, the inclined cone 402 pushes the sliding rod 405 to stretch out the support column 403 under the support of the spring 406 to adjust the width, suitable for fixing PE bottle caps of different sizes, and the motor 501 drives the small belt The wheel 502 drives the large pulley 504 to rotate through the transmission belt 503, and the large pulley 504 drives the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com