Production process of solvent-free composite aluminum-plated bag

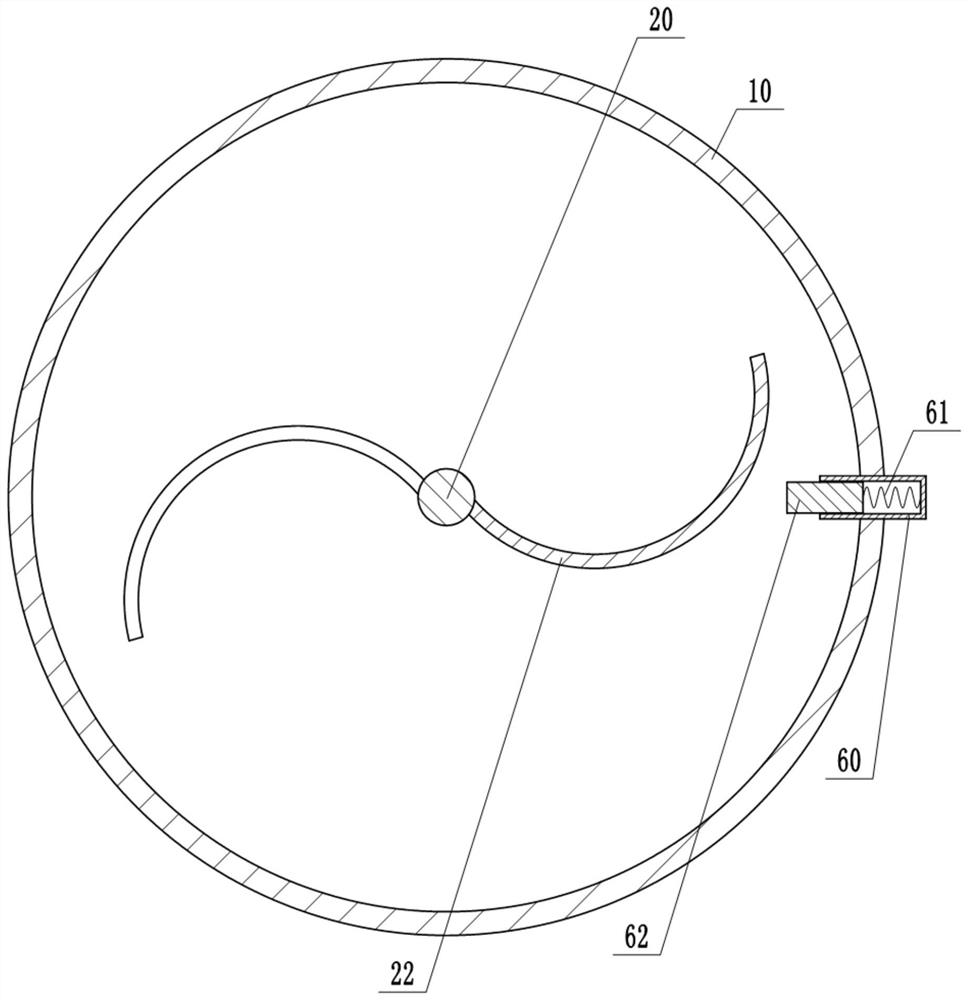

A solvent-free laminating machine and production process technology, which can be used in layered products, devices for coating liquid on surfaces, lamination devices, etc., and can solve problems such as sealing and high temperature resistance that cannot well meet the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A production process of a solvent-free composite aluminized bag, comprising the following processing steps:

[0034] (1) Install the printing film and aluminized film to be compounded on a solvent-free compounding machine.

[0035] (2) Deploy solvent-free two-component polyurethane adhesive: first preheat the solvent-free two-component polyurethane adhesive at 35°C; heat component A of the polyurethane adhesive at a temperature of 42°C, and heat the polyurethane Heat the component B of the adhesive at 40°C to soften the polyurethane adhesive; fully mix the component A of the polyurethane adhesive with the component B of the polyurethane adhesive in a ratio of 100:60 to obtain a mixed solution, and use the mixed solution within 20 minutes . The component A of the polyurethane adhesive used in this program is the brand WD8262A produced by Shanghai Kangda Chemical New Material Co., Ltd., and the component B of the polyurethane adhesive used is the brand WD8262B produced b...

Embodiment 2

[0052] A production process of a solvent-free composite aluminized bag, comprising the following processing steps:

[0053] (1) Install the printed film and aluminized film to be compounded on a solvent-free compound machine;

[0054] (2) Deploying solvent-free two-component polyurethane adhesive: first preheat the solvent-free two-component polyurethane adhesive at 34°C; heat component A of the polyurethane adhesive at a temperature of 43°C, and place the polyurethane Heat component B of the adhesive at 40°C to soften the polyurethane adhesive; fully mix component A of the polyurethane adhesive with component B of the polyurethane adhesive at a ratio of 100:58 to obtain a mixed solution, and use the mixed solution within 20 minutes ;

[0055] (3) Debugging: first debug the solvent-free composite machine at a machine speed of 15 m / min, and increase the machine speed to 180 m / min if the solvent-free composite machine works normally; unwind the printed film, and control the ten...

Embodiment 3

[0061] A production process of a solvent-free composite aluminized bag, comprising the following processing steps:

[0062] (1) Install the printed film and aluminized film to be compounded on a solvent-free compound machine;

[0063] (2) Deploying solvent-free two-component polyurethane adhesive: first preheat the solvent-free two-component polyurethane adhesive at a temperature of 36°C; heat component A of the polyurethane adhesive at 44°C, and heat the polyurethane Component B of the adhesive is heated at 41°C to soften the polyurethane adhesive; fully mix component A of the polyurethane adhesive with component B of the polyurethane adhesive at a ratio of 100:62 to obtain a mixed solution, and use the mixed solution within 20 minutes ;

[0064] (3) Debugging: first debug the solvent-free compound machine at a machine speed of 25 m / min, and increase the machine speed to 185 m / min if the solvent-free compound machine works normally; unwind the printed film, and control the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com