A kind of polysilane tire release agent

A polysilane and release agent technology, which is applied in the field of polysilane tire release agents, can solve the problems of insufficient compatibility between silicone and substrate, poor isolation effect, and low frequency of continuous demoulding, so as to improve the overall surface activity, Enhance adhesion, improve the effect of low surface energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The polysilane-based tire release agent of the present embodiment includes the mass percentage of the following components:

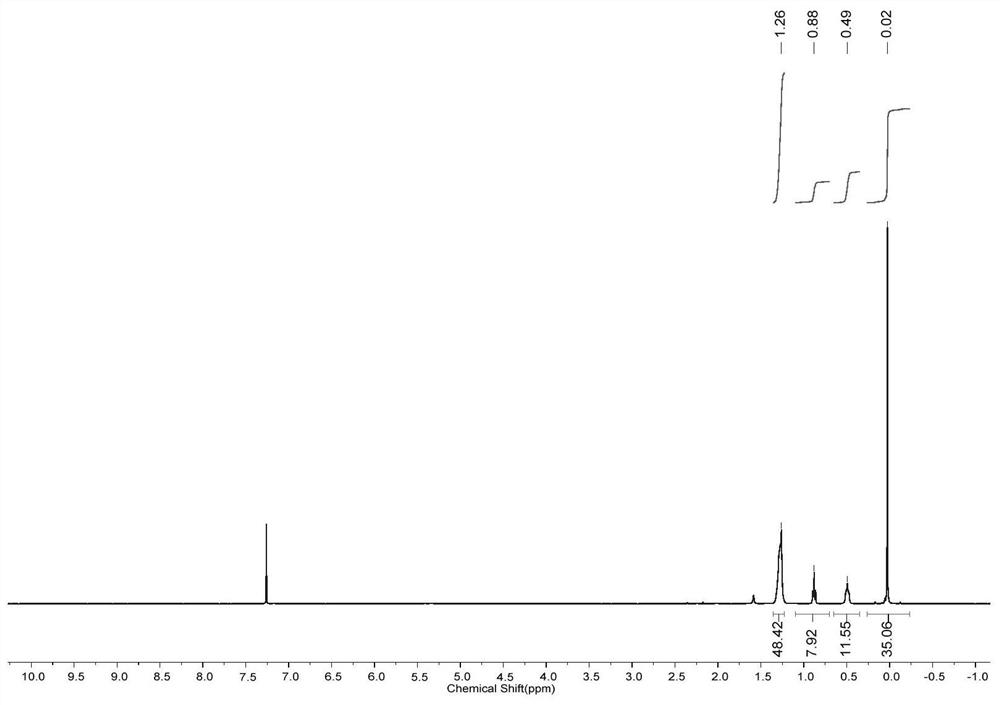

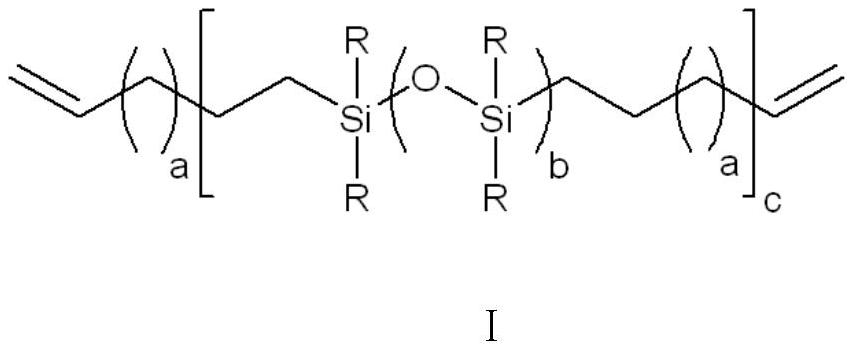

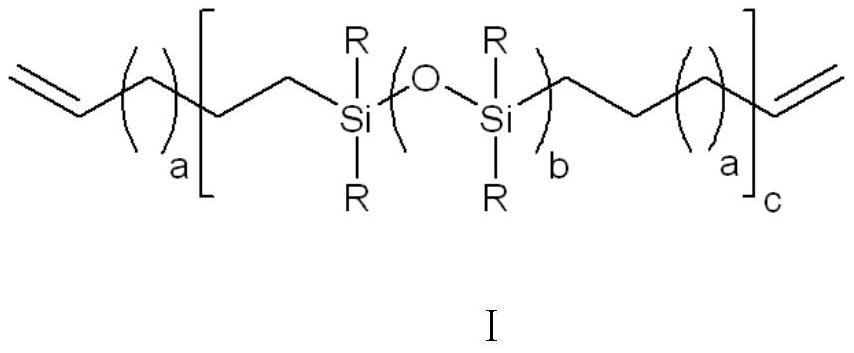

[0048] Long-chain alkyl-grafted polysilane: 12%; cross-linking agent: 1.0%; emulsifier: 2.0%; stabilizer: 0.7%, and the rest is deionized water; the structural formula of long-chain alkyl-grafted polysilane is as follows: formula I Compound:

[0049]

[0050] In formula I, when R is selected from butyl group, a is selected from an integer of 2-14, b is selected from an integer of 1-4, and c is an integer of 1-5; wherein the cross-linking agent is 1,4-xylylene Thiol, glycerol monostearate as emulsifier, zinc calcium stabilizer as stabilizer, and ingredients of the above-mentioned release agent are prepared according to a total mass percentage of 100%.

[0051] For the preparation method of the above-mentioned release agent, it can be obtained by the following method: the corresponding mass percentage of long-chain alkyl graft polysilane is slo...

Embodiment 2

[0055] The polysilane-based tire release agent of the present embodiment includes the mass percentage of the following components:

[0056] Long-chain alkyl-grafted polysilane: 16%; cross-linking agent: 1.0%; emulsifier: 1.5%; stabilizer: 0.6%, and the rest is deionized water; the structural formula of long-chain alkyl-grafted polysilane is as follows: formula I Compound:

[0057]

[0058] In formula I, R is selected from C 1 -C 4 The straight-chain alkyl group, a is selected from the integers of 2-14, b is selected from the integers of 1-4, c is the integer of the average number of 1-5; the cross-linking agent is 4,4-dimercaptostilbene , the emulsifier adopts fatty alcohol polyoxyethylene ether, the stabilizer adopts polyethylene glycol, and the components of the above-mentioned release agent are prepared according to a total mass percentage of 100%. The specific preparation method of the above-mentioned long-chain alkyl-grafted polysilane can be the same as the corresp...

Embodiment 3

[0061] The polysilane-based tire release agent of the present embodiment includes the mass percentage of the following components:

[0062] Long-chain alkyl-grafted polysilane: 14%; cross-linking agent: 0.8%; emulsifier: 1.0%; stabilizer: 0.4%, and the rest is deionized water; the structural formula of long-chain alkyl-grafted polysilane is as follows: formula I Compound:

[0063]

[0064] In formula I, R is selected from methyl, a is 4, b is 1, and c is 3; the cross-linking agent is 2,2'-thiobis(ethanethiol), the emulsifier is Tween 60, and the stable The agent adopts sodium polyacrylate, and the components of the above-mentioned release agent are prepared according to a total mass percentage of 100%. The specific preparation method of the above-mentioned long-chain alkyl-grafted polysilane can be the same as the corresponding method in Example 1, and will not be repeated here.

[0065] The preparation method of the above-mentioned release agent in this embodiment is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com