Graphene coating aluminum foil coating device

A coating equipment, graphene technology, applied in graphene, coating, electrode current collector coating and other directions, can solve problems such as safety hazards and battery discharge too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

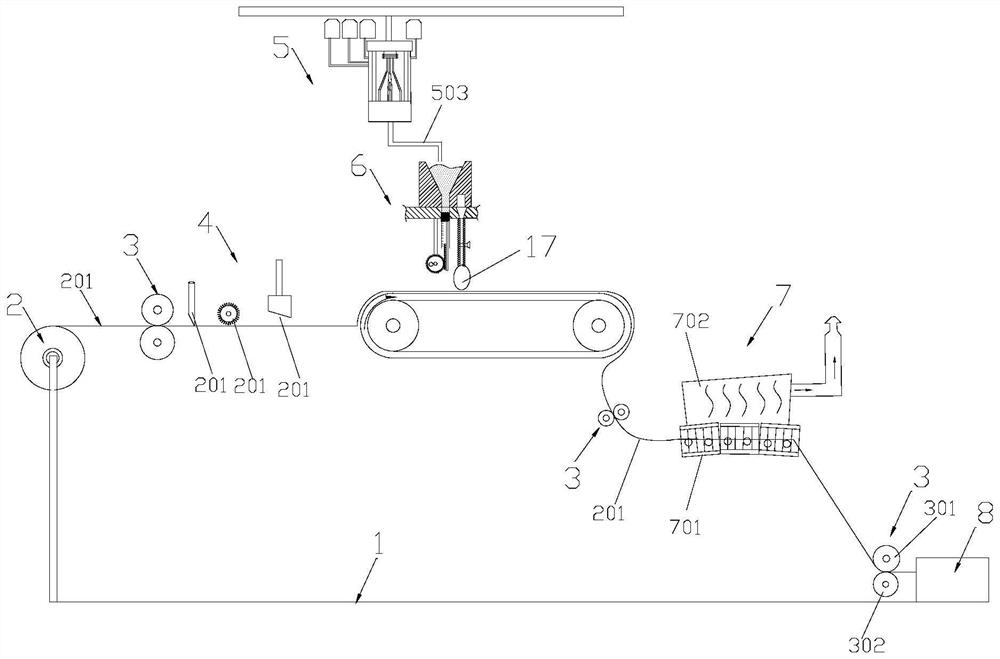

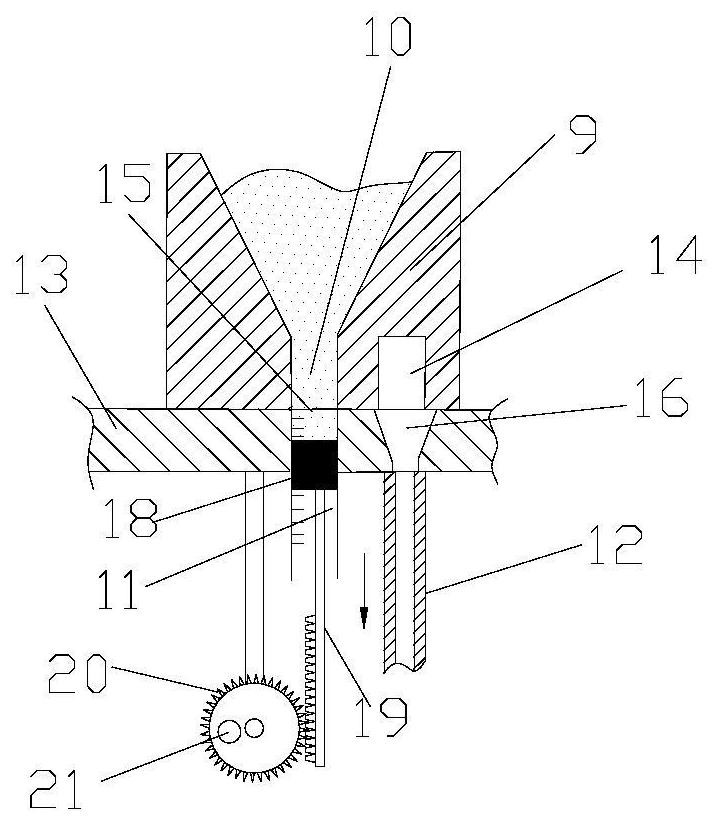

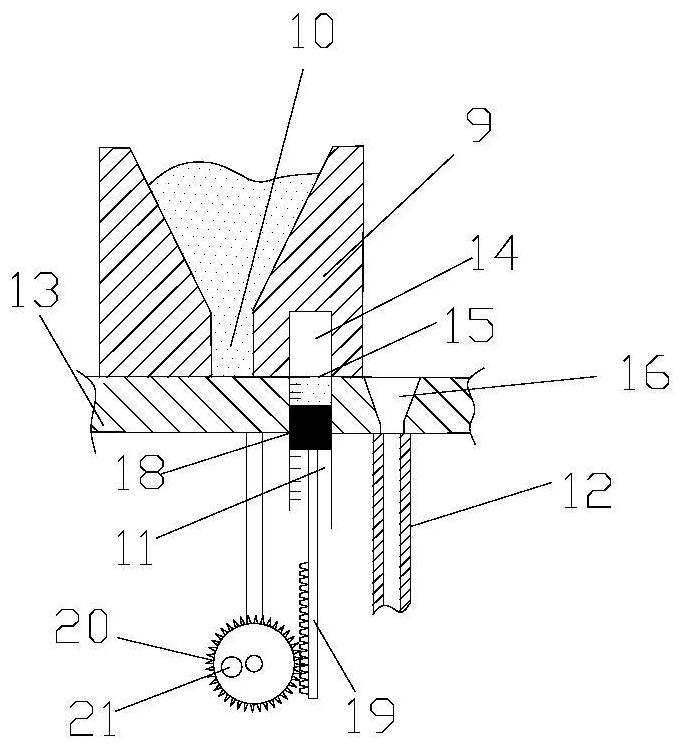

[0040] refer to Figure 1-7 , the present invention provides a technical solution:

[0041] Please refer to figure 1 , a graphene-coated aluminum foil coating equipment, including a base 1, an aluminum foil roll 2 wound on the base 1, several tensioning mechanisms 3, a cleaning mechanism 4, a stirring mechanism 5, and a coating mechanism 6 , a heating mechanism 7 and a storage mechanism 8, the aluminum foil roll 2 includes an aluminum foil substrate 201, and the cleaning mechanism 4, the coating mechanism 6 and the heating mechanism 7 are arranged at intervals in sequence along the walking direction of the free end of the aluminum foil substrate 201 Above the aluminum foil substrate 201, the stirring mechanism 5 is distributed above the coating mechanism 6, the free end of the aluminum foil substrate 201 enters the storage mechanism 8 at a constant speed, and several tensioning mechanisms 3 are distributed in sequence Between the aluminum foil roll 2 and the cleaning mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com