Sedimentation type cyclic fermentation device

A cyclic fermentation and settling technology, which is applied in the direction of dough fermenter, mixing/kneading with vertical installation tools, baking, etc., can solve the problems of high manufacturing cost, uneven fermentation degree, and difficulty in cleaning, and can reduce equipment Quantity, good mixing effect, easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

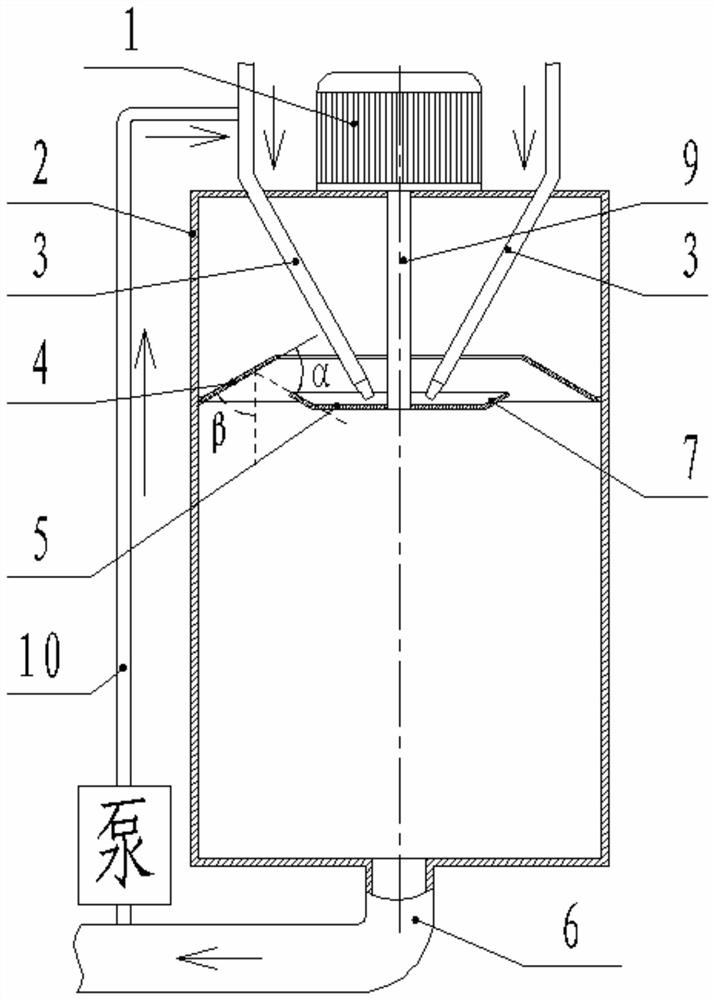

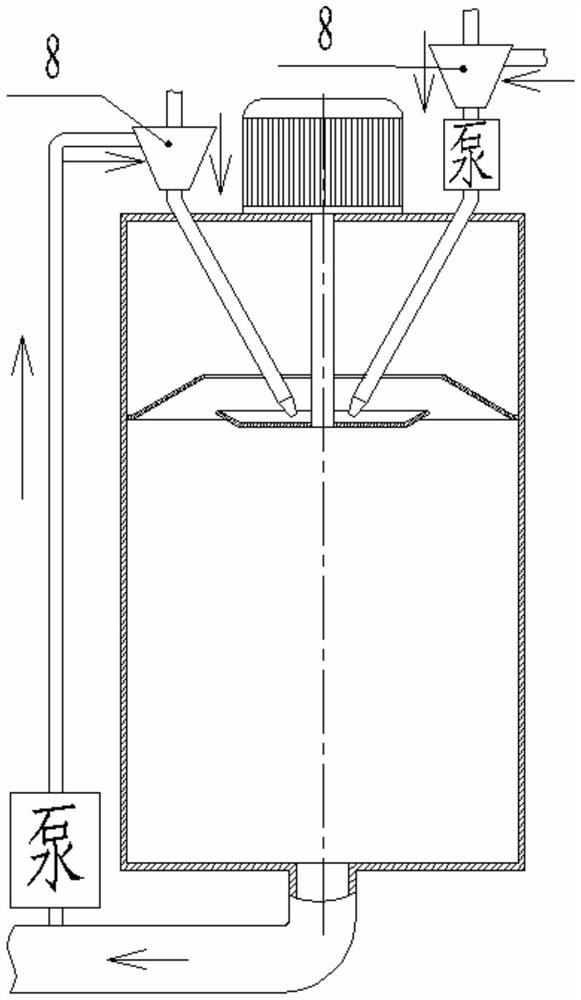

[0020] Such as figure 1 As shown, the present invention comprises motor 1, drive shaft 9, centrifugal disc 5 and fermentation tank 2, and motor 1 is installed in the center of fermentation tank 2 tops, and the upper end of drive shaft 9 is connected with the output shaft of motor 1, and described centrifugal disc 5 Connected to the lower end of the drive shaft 9. In the above structure, the centrifugal disc 5 and the drive shaft 9 rotate under the drive of the motor, and the fermenter 2 provides space for the fermentation of the batter.

[0021] The top of the fermentor 2 is provided with a feed nozzle 3, the inlet end of the feed nozzle 3 is located outside the fermenter 2, and the outlet end of the feed nozzle 3 is inserted into the fermentor 2 and extends to the bottom of the centrifugal disc 5. above. When the material reaches the centrifugal disc 5 through the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com