Cosmetic production raw material drying device

A drying device and raw material technology, applied in drying, drying machine, heating device and other directions, can solve the problem that cosmetic raw materials are not easy to be completely dried, and achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

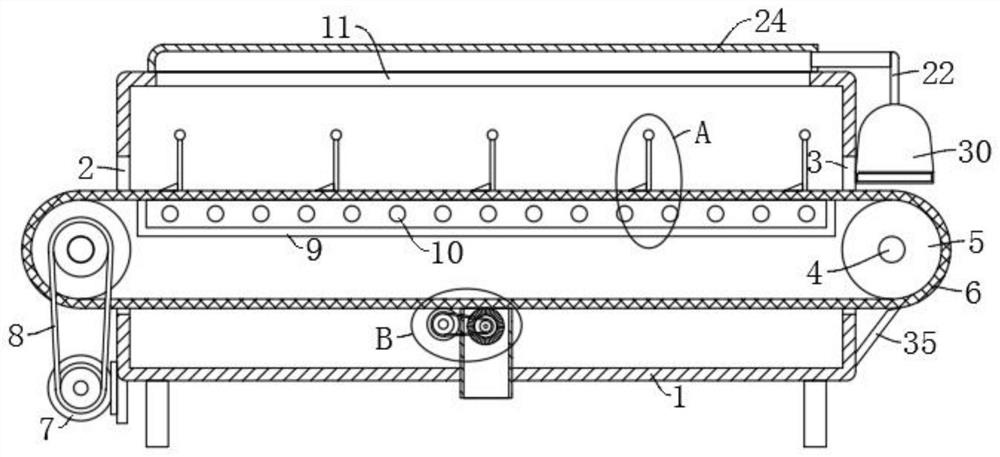

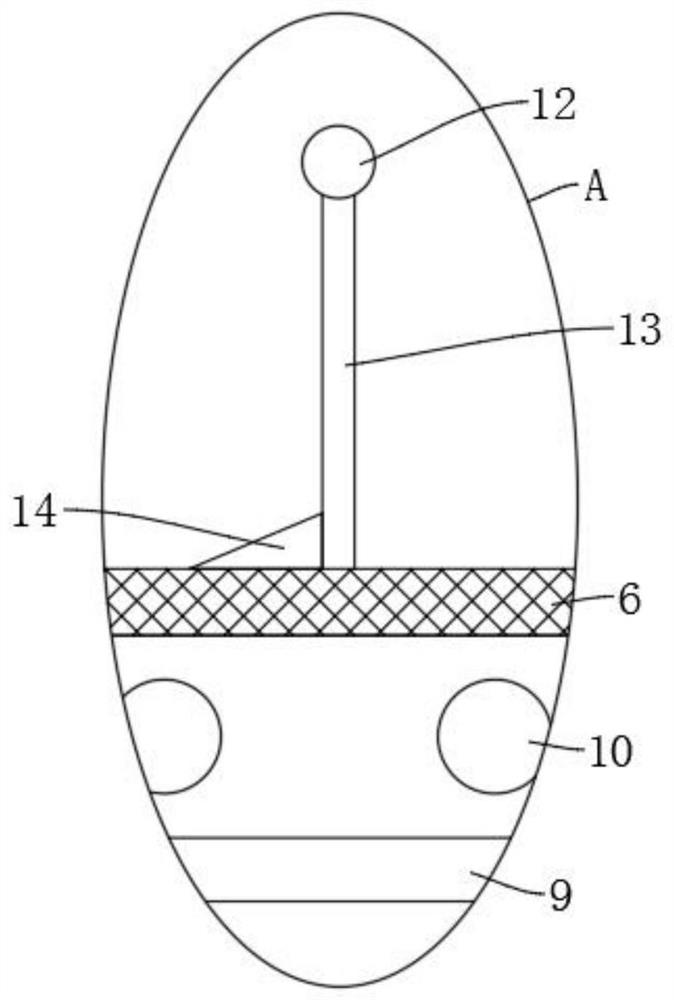

[0030] refer to Figure 1-5 , a raw material drying device for cosmetics production, comprising a drying box 1, an inlet 2 and an outlet 3 are respectively provided on both sides of the drying box 1, and a drum 5 is connected to the inlet 2 and the outlet 3 through a rotating shaft 4. Two The outer wall of the cylinder 5 is covered with a conveying belt 6, and the side wall of the drying box 1 is fixedly equipped with a motor 7, and the output shaft of the motor 7 is connected to one of the cylinders 5 through a first chain 8 transmission connection. The inside is fixedly connected with a heat conduction plate 9 that fits the inner top of the conveyor belt 6, and the inside of the heat conduction plate 9 is fixedly equipped with a heating wire 10, and a plurality of evenly distributed horizontal bars 12 are fixedly connected between the inner walls of the drying box 1. The lower ends of each cross bar 12 are all fixedly connected with the triangular block 14 that fits with the...

Embodiment 2

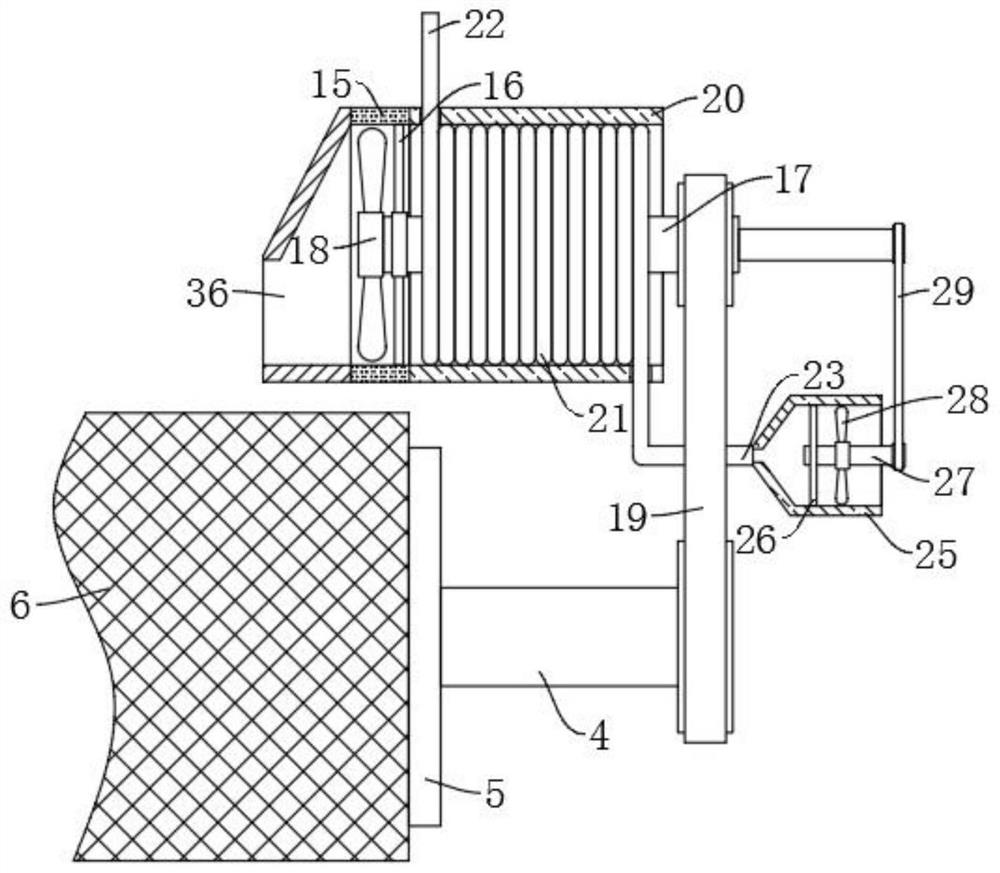

[0034] refer to figure 1 and figure 2, is basically the same as Embodiment 1, furthermore: the blowing device includes a first cylinder 15 fixedly connected to the side wall of the drying box 1, and the first cylinder 15 is rotatably connected with a first rotating rod through a first bracket 16 17. One end of the first rotating rod 17 is fixedly connected with a blowing fan blade 18, the wind direction of the blowing fan blade 18 is set parallel to the drum 5 in the outlet 3, and the other end of the first rotating rod 17 and the rotating shaft 4 pass through the second chain 19 transmission connection, a recovery heating device is provided between the exhaust groove 11 and the fan blade 18, when the cosmetic raw material is transported to the outlet 3, the rotating shaft 4 drives the first rotating rod 17 to rotate through the second chain 19, and the first rotating rod 17 It will drive the blowing fan blade 18 to blow the raw material at the outlet 3, thereby blowing away...

Embodiment 3

[0037] refer to figure 1 and figure 2 , is basically the same as Embodiment 1, furthermore: the recovery heating device includes a gas collecting hood 24 fixedly connected to the upper end of the exhaust groove 11, and the rear side wall of the first cylinder 15 is fixedly connected with a second cylinder communicating with it 20. The inner wall of the second cylinder 20 is fixedly connected with a spiral delivery pipe 21, the input pipe 22 of the delivery pipe 21 is fixedly connected with the air outlet of the gas collecting hood 24, and the side wall of the drying box 1 is fixedly connected with a suction hood 25. The suction hood 25 is fixedly connected to the output pipe 23 of the delivery pipe 21. The inside of the suction hood 25 is rotatably connected to the second rotating rod 27 through the second bracket 26, and the end of the second rotating rod 27 is fixedly connected to the suction fan. The blade 28, the second rotating rod 27 and the first rotating rod 17 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com