Mechanically-sealed metal corrugated pipe compensation assembly

A technology of metal bellows and mechanical seals, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of destroying the mutual parallel fit relationship, poor seal end face fit stability, and increased leakage. The weight does not increase, the force is uniform and reasonable, and the effect of reducing the radial thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

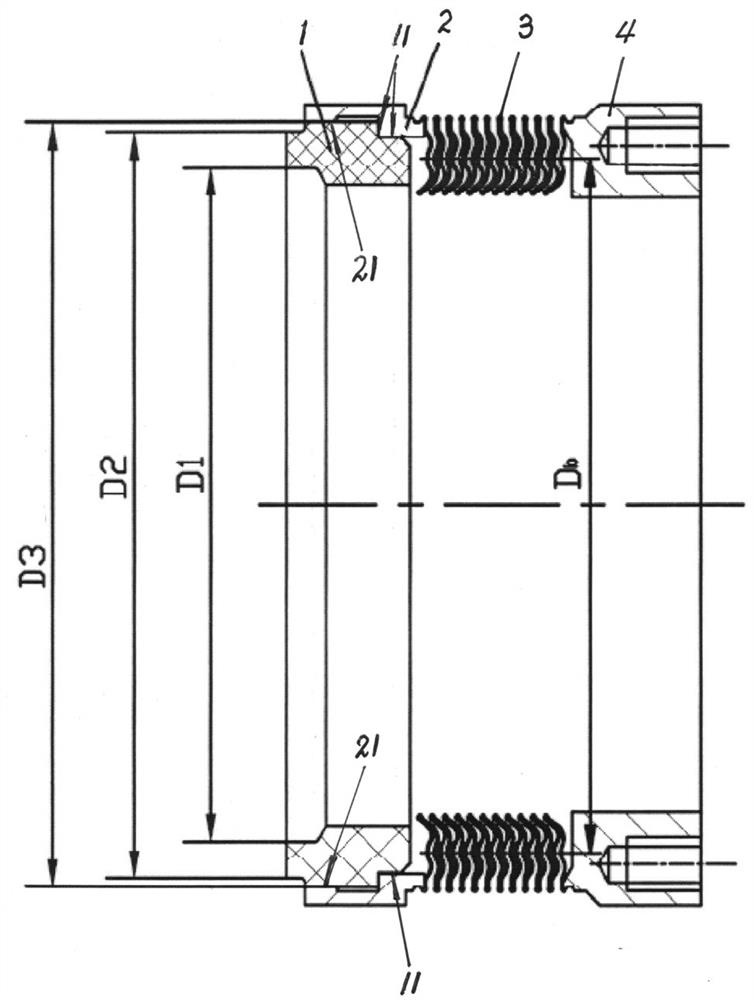

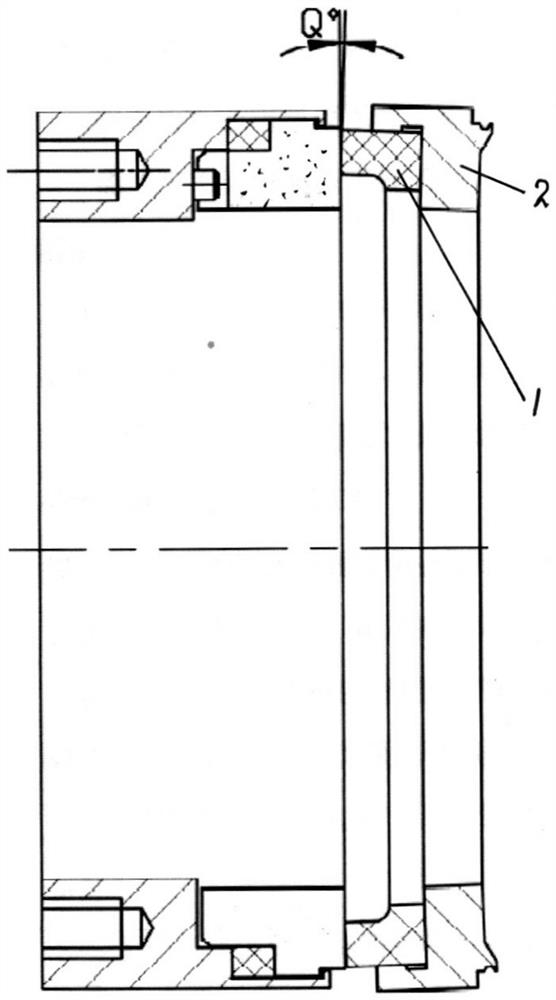

[0013] The metal bellows compensating assembly of the mechanical seal of the present invention is composed of a friction ring 1, a friction ring seat 2, a metal bellows 3, and a tailstock 4; the left and right ends of the metal bellows 3 are respectively welded to the friction ring seat 2 and the tailstock 4 The connection is characterized in that: an inner spigot 21 is provided at the left end of the friction ring seat 2, and an outer spigot 11 is provided at the right end of the friction ring 1, and the friction ring 1 and the friction ring seat 2 are matched through the above spigot, The inner spigot 21 of the friction ring seat 2 is fixedly connected with the outer circular surface of the friction ring 1 by interference fit.

[0014] The present invention is suitable for application conditions:

[0015] Pressure P≤4.0Mpa, temperature 176

[0016]

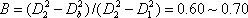

[0017] B-balance factor

[0018] D2- the outer diameter of the sealing end face (mm)

[0019] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com