Method for manufacturing fastener and fastener

A technology for fasteners and substrates, applied in the field of fastener manufacturing, can solve the problems of falling off the structure and reducing the yield of the final product, and achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following will refer to Figures 1 to 6 A method for manufacturing a fastener according to the present invention is described.

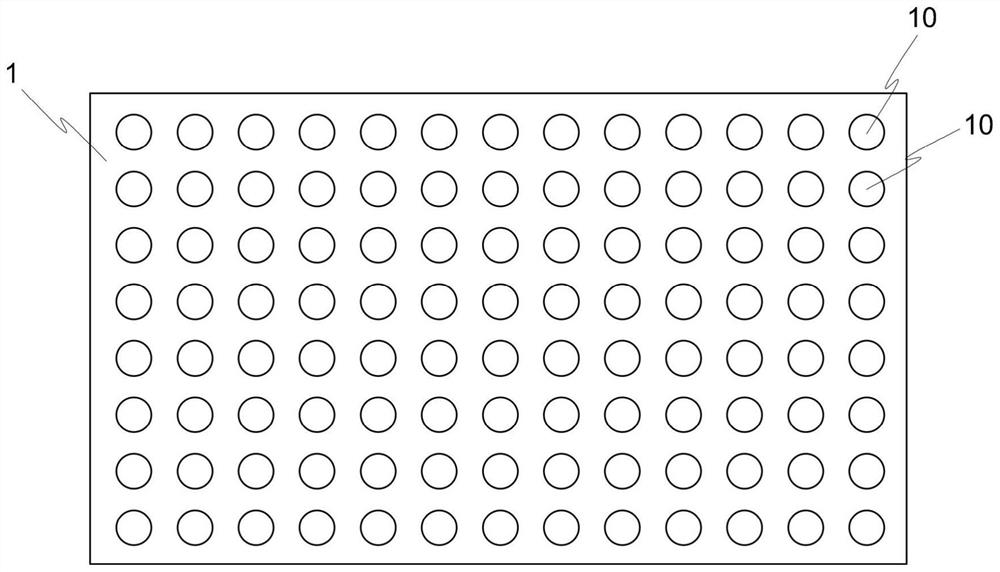

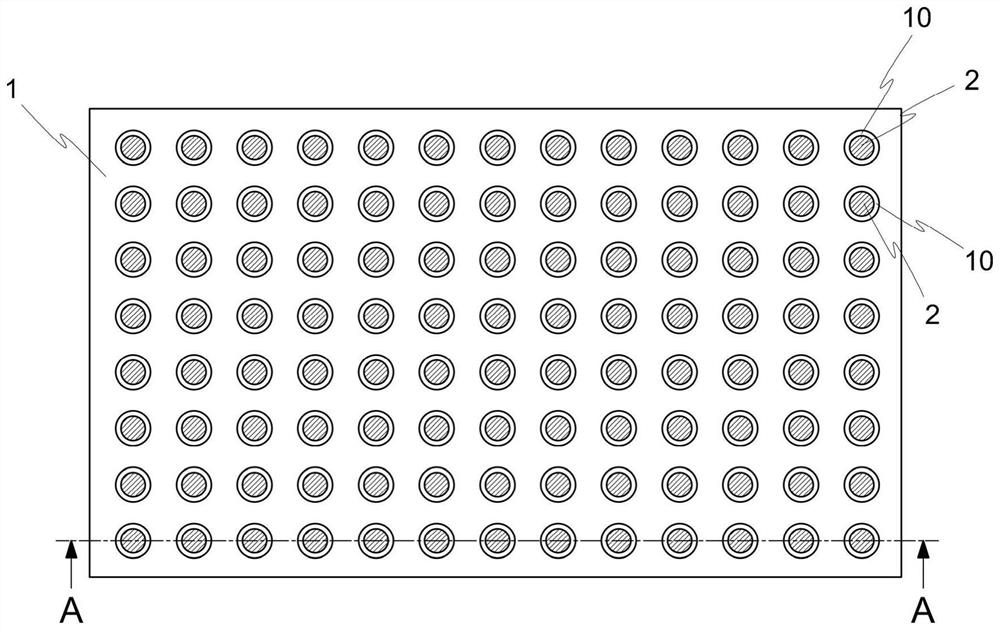

[0045] First, if figure 1 As shown, a substrate 1 is provided, and a plurality of through holes 10 are formed on the substrate 1 . Preferably, the through holes 10 are punched holes formed by punching process, and their arrangement can be designed according to the type of fastener to be formed. In this embodiment, the through holes 10 are arranged in an array pattern, but not limited thereto. For example, the through-holes 10 may be configured to be arranged in other patterns according to the design requirements of the final fastener (details will be described later).

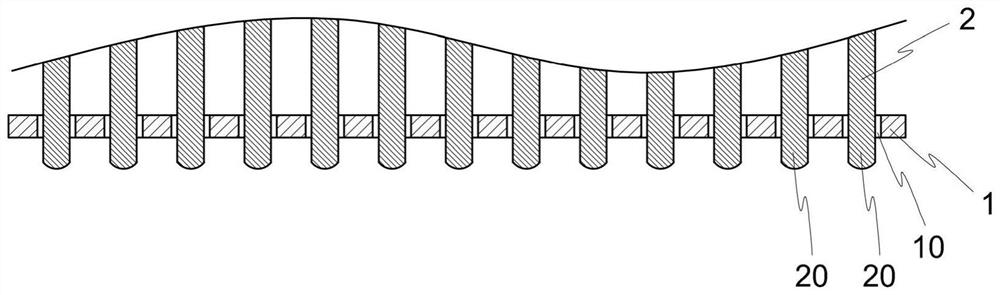

[0046] Next, if figure 2 and 3 As shown, a plurality of wire bodies 2 are correspondingly passed through a plurality of through holes 10 of the substrate 1 , so that ends 20 of the plurality of wire bodies 2 protrude from the substrate 1 . In this case, the end 20 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com