Production method of craft paper with high smoothness

A production method and a technology for kraft paperboard, applied in the field of papermaking technology, can solve the problem of low surface smoothness of kraft paperboard, and achieve the effects of high smoothness, improved smoothness, and increased bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

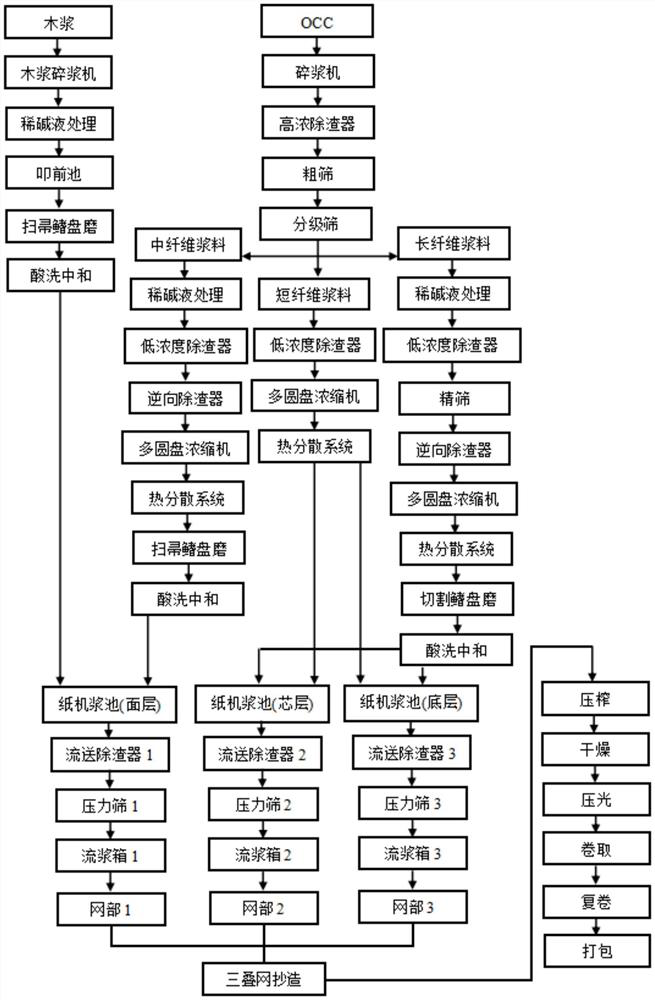

[0034] A method for producing kraft cardboard with high smoothness, comprising the following processes:

[0035] (1) Waste paper treatment process

[0036] a. Pulping: Put the waste paper into the pulper to get waste paper pulp; the waste paper is container board (OCC), which can be Chinese waste paper, American waste paper or European waste paper, so as to reduce wood pulp The use of materials can effectively reduce the manufacturing cost of enterprises, save resources and reduce damage to the environment.

[0037] b. Purification and sieving: the waste paper pulp is passed through a high-concentration slag remover, a coarse screen, and a classifying screen in sequence to obtain long-fiber pulp, medium-fiber pulp and short-fiber pulp. Among them, the high-concentration deslagging machine can effectively remove impurities such as sand, glass, screws, steel needles, staples, and metal flakes in the waste paper slurry, and the coarse sieve can further screen out impurities, imp...

Embodiment 2

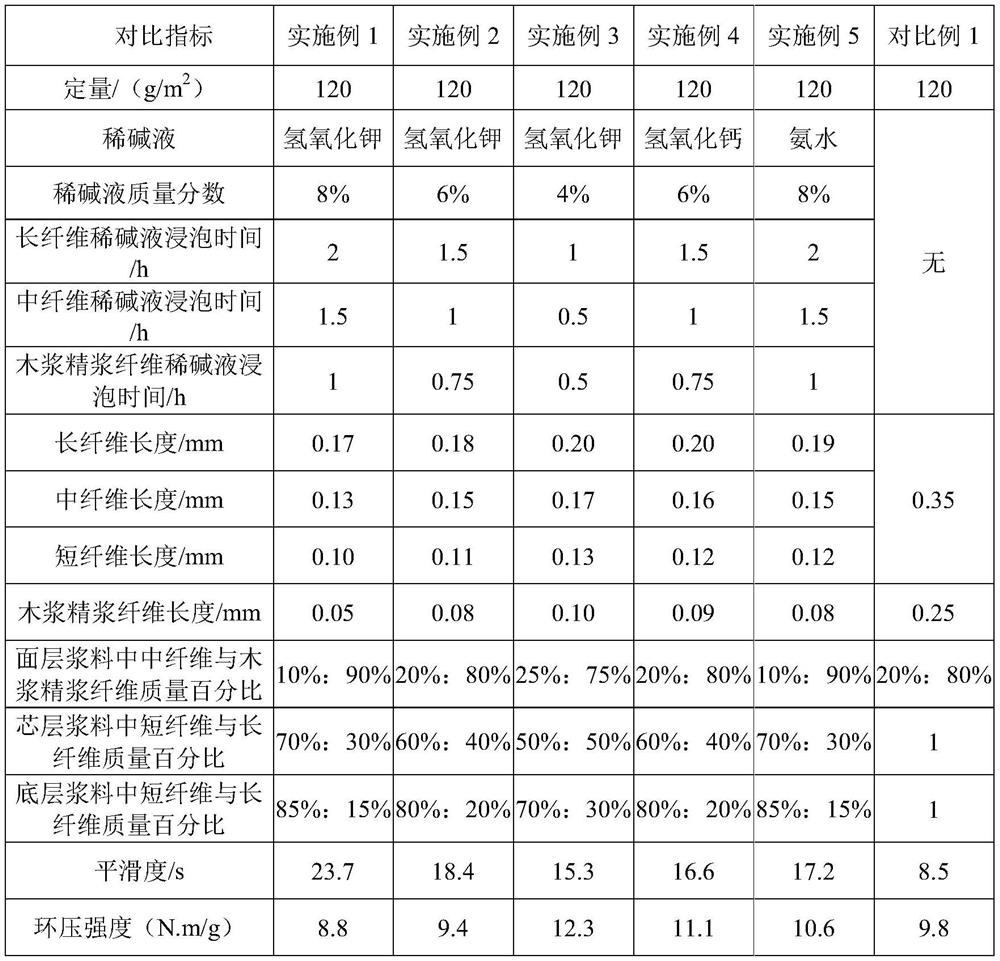

[0048] Except that the following are different from Example 1, others are the same as Example 1:

[0049] The dilute lye used in the above process is potassium hydroxide solution with a mass fraction of 6%; in the long fiber swelling alkaline beating process, the long fiber slurry is soaked in dilute lye for 1.5 hours; the medium fiber swelling alkaline beating During the treatment, the medium fiber slurry was soaked in dilute alkali solution for 1 hour; in the wood pulp fiber swelling alkaline beating treatment, the wood pulp slurry was soaked in dilute alkali solution for 0.75 hours; the long fiber in the long fiber slurry The length is 0.18mm, the length of medium fiber in medium fiber pulp is 0.15mm, the length of short fiber in short fiber pulp is 0.11mm; the length of fiber in fine wood pulp is 0.08mm; (1) The mass percentage of medium fiber refined pulp prepared by process (2) and wood pulp refined pulp prepared by process (2) is 20%: 80%; The mass percentage of pulp a...

Embodiment 3

[0051] Except that the following are different from Example 1, others are the same as Example 1:

[0052] The dilute lye used in the above process is potassium hydroxide solution with a mass fraction of 4%; in the long fiber swelling alkaline beating process, the long fiber slurry is soaked in dilute lye for 1 hour; the medium fiber swelling alkaline beating During the treatment, the medium fiber pulp was soaked in dilute alkali solution for 0.5 hours; in the wood pulp fiber swelling alkaline beating treatment, the wood pulp pulp was soaked in dilute alkali solution for 0.5 hours; the long fiber in the long fiber pulp The length is 0.20mm, the length of medium fiber in medium fiber pulp is 0.17mm, the length of short fiber in short fiber pulp is 0.13mm; the length of fiber in fine wood pulp is 0.10mm; (1) The mass percentage of medium fiber refined pulp prepared by process (2) and wood pulp refined pulp prepared by process (2) is 25%: 75%; The mass percentage of uniform mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com