Method for removing phenylurea herbicide chlortoluron in water by using ultraviolet/persulfate combined process

A persulfate and combined process technology, applied in water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problem that it is difficult to meet the discharge requirements, the degradation effect of chloromylon is small, and the green myelon cannot be effectively removed. Mellon and other problems, to achieve the effect of easy control of reaction parameters, lower concentration, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for removing the phenylurea herbicide chlorotoluron in water by an ultraviolet / persulfate combined process, comprising the following steps:

[0048] Use ultrapure water to configure the initial concentration of chlorotoluron as 8 μM, add phosphate buffer solution, and use NaOH and H under the combined process of UV / persulfate 2 SO 4 Adjust the initial pH of the chlorotoluron solution to 7, add persulfate solution to the chlorotoluron solution, so that the dosage of persulfate is 160 μM, and carry out ultraviolet irradiation at the same time, and control the ultraviolet irradiation intensity to 2.43mW / cm 2 , the reaction temperature was controlled at 25°C.

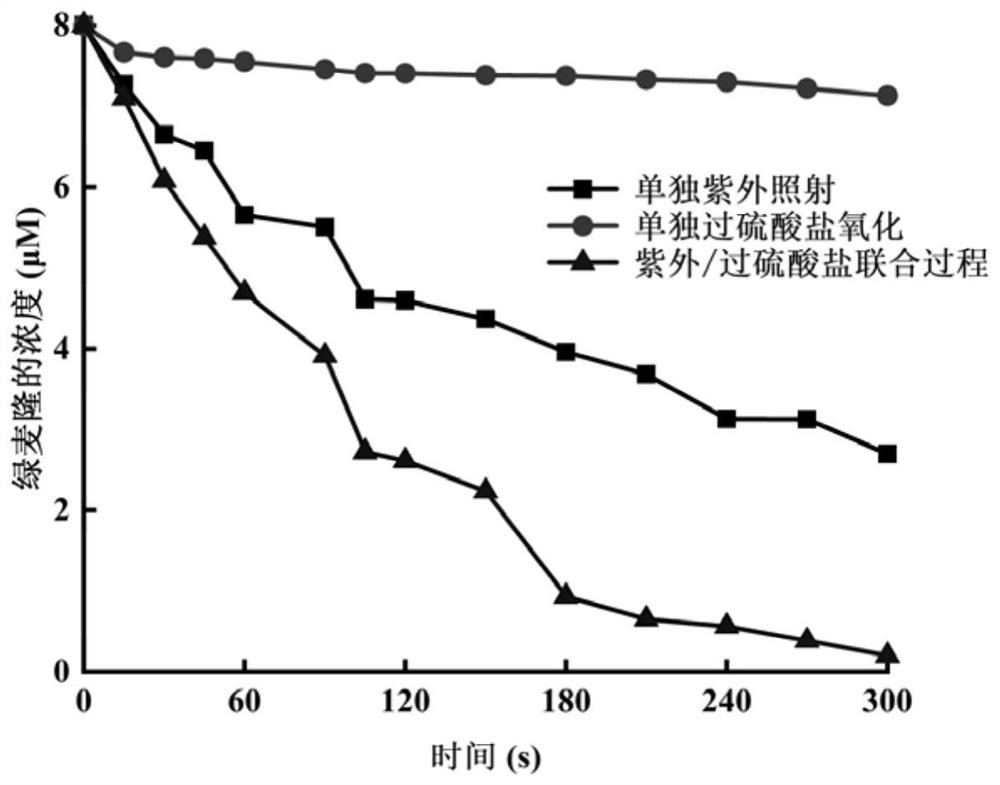

[0049] The curves of the chlorotoluron concentration over time under the three processes of independent ultraviolet irradiation (comparative example 2), independent persulfate oxidation (comparative example 1) and ultraviolet / persulfate combined process (embodiment 1) are as follows figure 1 shown.

[005...

Embodiment 2

[0052] A method for removing the phenylurea herbicide chlorotoluron in water by an ultraviolet / persulfate combined process, comprising the following steps:

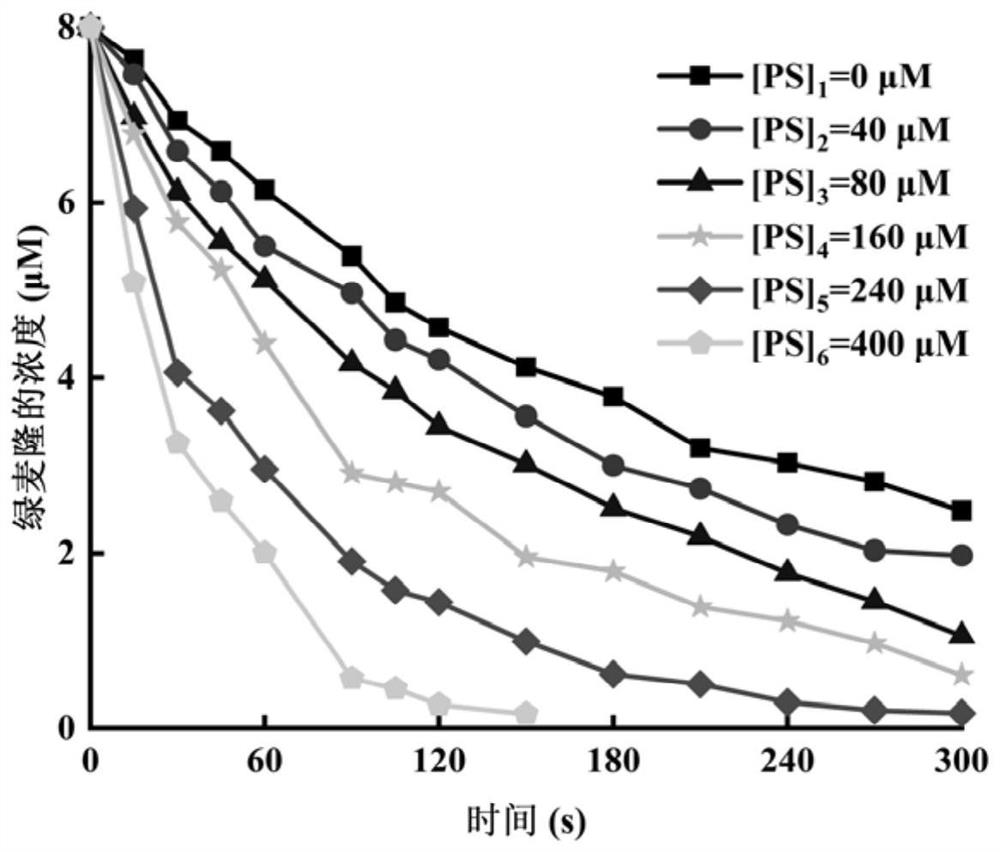

[0053] Use ultrapure water to prepare the initial concentration of chlorotoluron as 8 μM, and use NaOH and H 2 SO 4 Adjust the initial pH of the chlorotoluron solution to 7, add persulfate solution to the chlorotoluron solution, control the initial addition of persulfuric acid to make the concentrations respectively 0, 40, 80, 160, 240 and 400 μM, and carry out ultraviolet irradiation at the same time, Control the UV intensity to 2.43mW / cm 2 , after 5 minutes of reaction, the removal rate of chlorotoluron is detailed in figure 2 .

[0054] From figure 2 It can be seen that with the increase of persulfate dosage, the removal rate of chlorotoluron is significantly accelerated. Under the condition that the ultraviolet intensity remains constant, with the increase of the dosage of persulfate in the system, the SO produ...

Embodiment 3

[0056] A method for removing the phenylurea herbicide chlorotoluron in water by an ultraviolet / persulfate combined process, comprising the following steps:

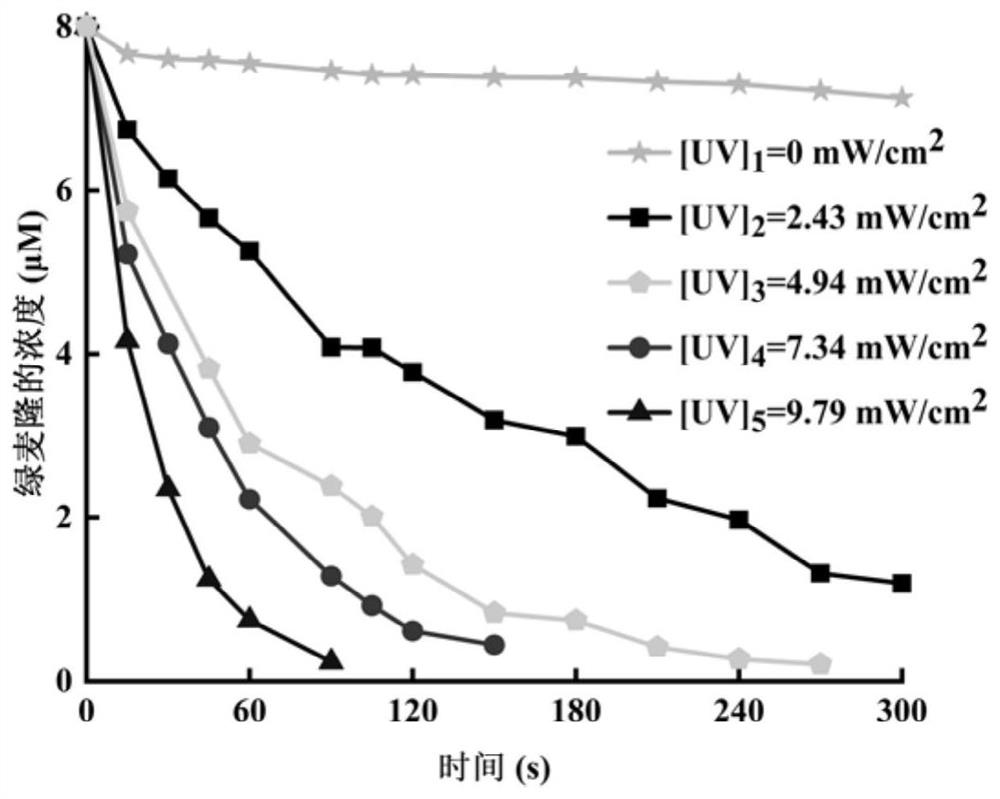

[0057] Use ultrapure water to configure the initial concentration of chlorotoluron to 8 μM, and use NaOH and H 2 SO 4 Adjust the initial pH of the chlorotoluron solution to 7, add persulfate solution to the chlorotoluron solution to make the concentration 160μM, and carry out ultraviolet irradiation at the same time, and control the ultraviolet intensity to be 2.43, 4.94, 7.34 and 9.79mW / cm respectively 2 , at a temperature of 25°C, the basic degradation times of chlorotoluron are 90s, 150s, 270s, and 300s, respectively.

[0058] From image 3 It can be seen that with the gradual increase of the intensity of ultraviolet light, the degradation rate of chlorotoluron gradually increased. When the intensity of ultraviolet light increases, the photon energy in the solution increases, and the SO produced by persulfate irradi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com