Cleaning method for preventing surface gloss of rolled mirror surface aluminum from being reduced

A mirror aluminum, gloss technology, applied in the direction of metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of surface gloss attenuation, can not meet the special requirements of surface gloss, etc., to maintain surface gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

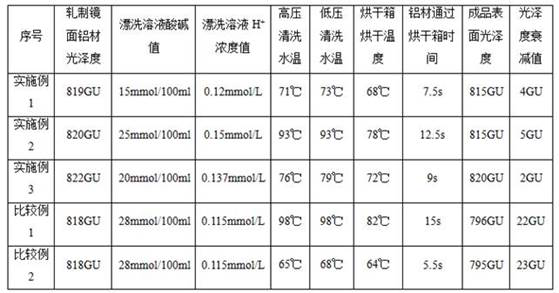

Embodiment 1

[0023] Example 1: Select a rolled 1070 aluminum alloy mirror surface aluminum material with a surface gloss of 819GU for cleaning. The specific steps and process parameters are as follows:

[0024] (1) Use a mixed acid solution with hydrofluoric acid and sulfuric acid as the main components, and mix it with demineralized water. The acid value during mixing is controlled according to 15mmol / 100ml, and the concentration of hydrogen ions in the solution is controlled according to 0.12mmol / 100ml. Control, prepare a weakly acidic rinsing solution, use the prepared rinsing solution to rinse the rolled 1070 aluminum alloy mirror surface aluminum to remove residual oil and aluminum powder on the surface of the aluminum, and perform the first squeeze after rinsing;

[0025] (2) Use high-pressure water with a pressure value of 3Mpa to perform high-pressure cleaning on the rolled 1070 aluminum alloy mirror surface aluminum material after the previous step, and the temperature of the high-...

Embodiment 2

[0031] Example 2: Select the rolled 1070 aluminum alloy mirror surface aluminum material with a surface gloss of 820GU for cleaning. The specific steps are roughly the same as in Example 1. The difference is the control of the process parameters. Only the different process parameters are listed below. .

[0032] (1) When preparing the rinse solution, the acid value is controlled at 25mol / L, and the hydrogen ion concentration in the solution is controlled at 0.15mmol / L;

[0033] (2) The water temperature during high-pressure cleaning is 93°C, and the water temperature during low-pressure cleaning is 93°C;

[0034] (3) During drying, the drying temperature in the drying box is 78°C, and the time for the aluminum material to pass through the drying box is 12.5s.

[0035] After the cleaning is completed according to the above method, the glossiness of the cleaned aluminum is tested. The measured result is 815GU, and the attenuation is 5GU. Gloss requirements.

Embodiment 3

[0036] Example 3: Select the rolled 1070 aluminum alloy mirror surface aluminum material with a surface gloss of 822GU for cleaning. The specific steps are roughly the same as in Example 1. The difference is the control of the process parameters. The following only lists the different process parameters. .

[0037] (1) When preparing the rinse solution, the acid value is controlled at 20mmol / 100ml, and the hydrogen ion concentration in the solution is controlled at 0.137mmol / 100ml;

[0038] (2) The water temperature during high-pressure cleaning is 76°C, and the water temperature during low-pressure cleaning is 79°C;

[0039] (3) When drying, the drying temperature in the drying box is 72°C, and the time for the aluminum material to pass through the drying box is 9s.

[0040]After the cleaning is completed according to the above method, the glossiness of the cleaned aluminum is tested. The test result is 820GU, and the attenuation is 2GU. Gloss requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com