Application of sponge to clothes and clothes made of full sponge

A sponge and clothing technology, which is applied in the field of clothing made of all-sponge, can solve the problems of rising labor costs, non-degradable properties, and rising overall clothing costs, so as to reduce the process and cost of each link, and is safe, non-toxic and harmless , Conducive to the effect of intelligent production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0033] Preparation of short sleeves of pure sponge

[0034] Cut the sponge sheet into front piece, back piece, sleeve piece and collar piece, hot-melt glue the front piece and back piece, place the adhesive edge on the side, roll the sleeve piece into a sleeve tube, and hot-melt glue the butt edge The adhesive edge is placed on the lower side, the collar piece connects the corresponding positions of the front piece and the back piece, and the adhesive piece is placed at a position where the collar piece can be folded and covered (that is, the outside of the collar piece).

[0035] Preparation of multilayer sponge structures

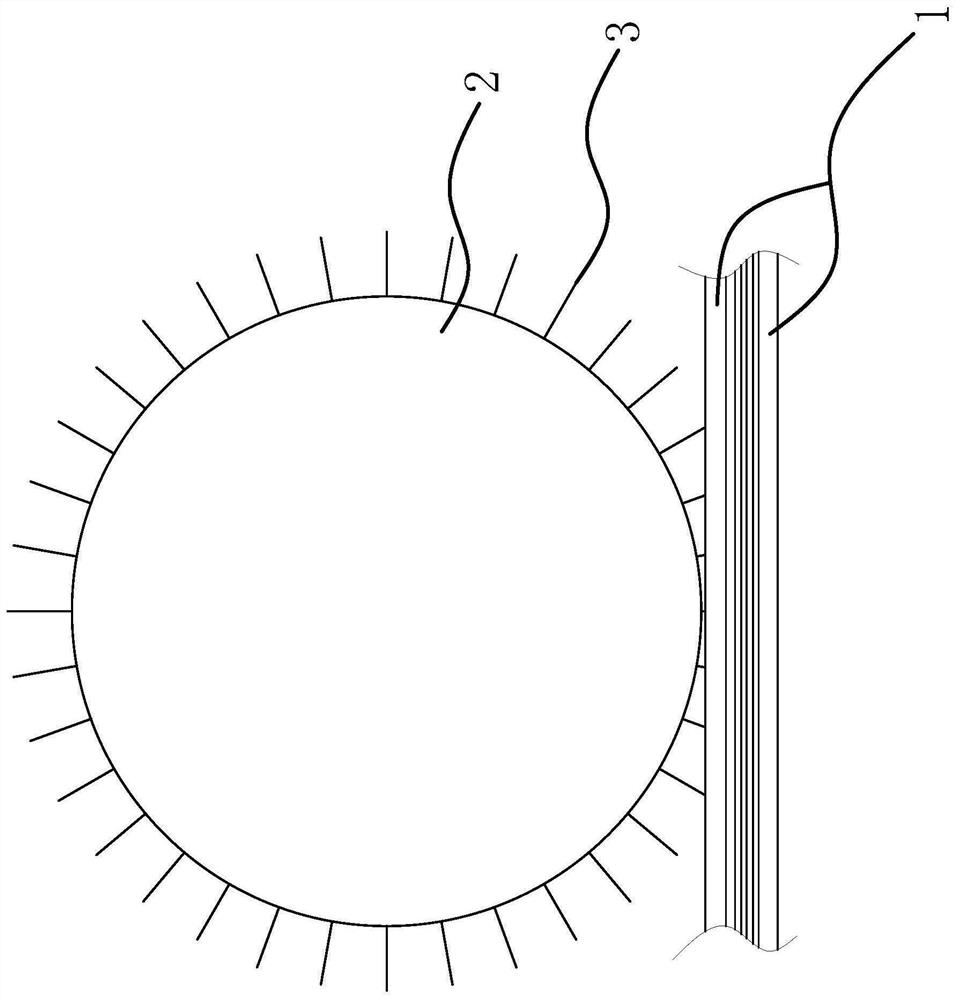

[0036] The cut sponge sheet is clamped by the clamp, so that the roller 2 rolls over one of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com