Selection method for determining test stress corresponding to test load during spring prestressing treatment

A technology for testing stress and load. It is used in special data processing applications, electrical digital data processing, instruments, etc., and can solve problems such as high stress, small winding ratio, and large deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

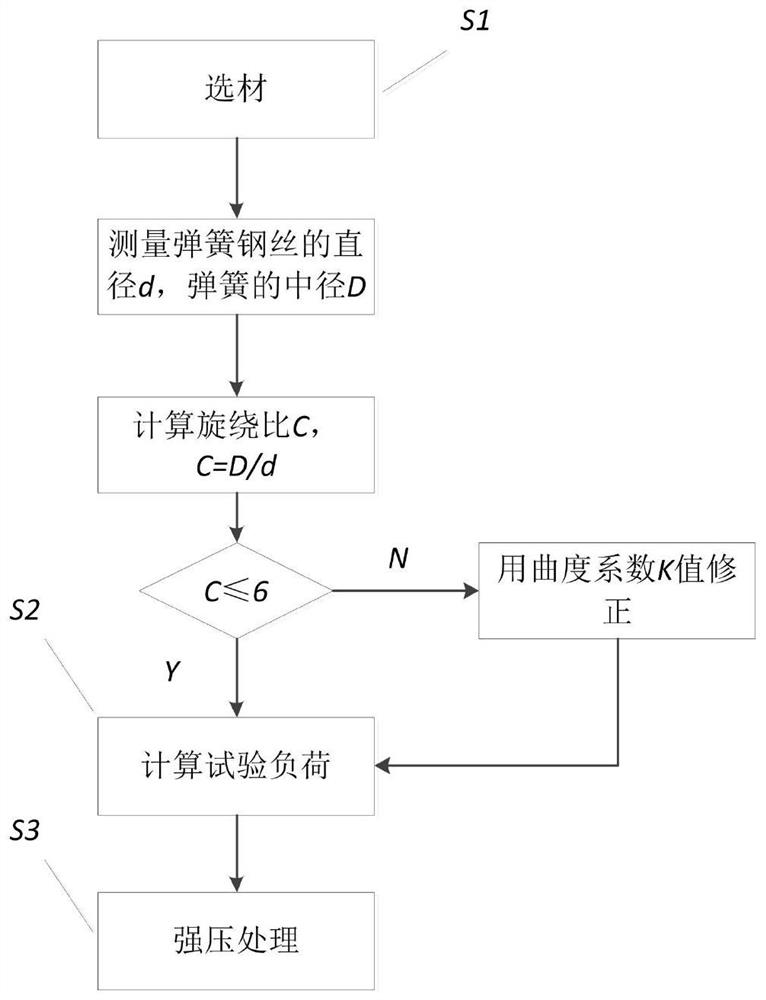

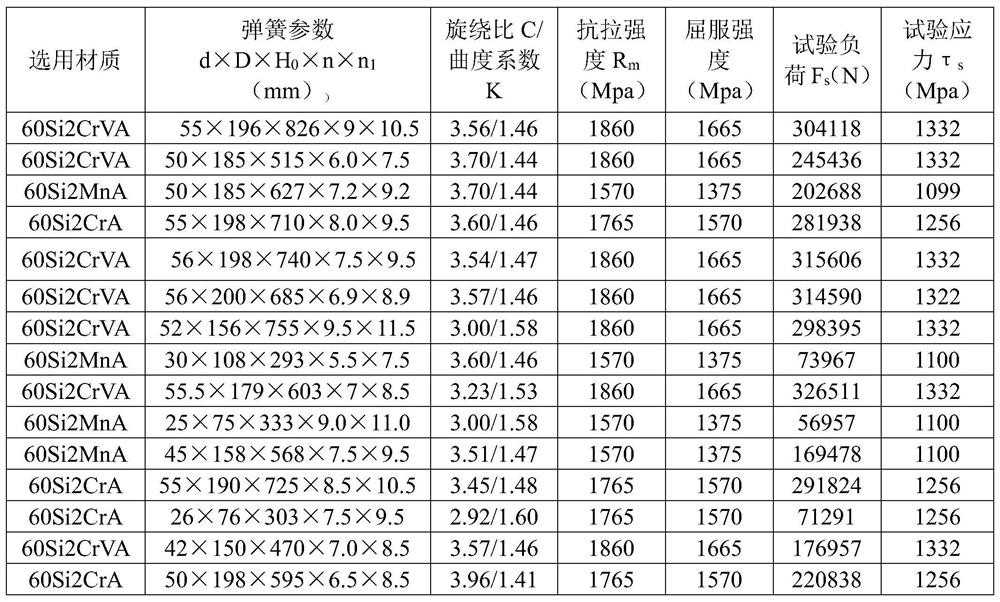

[0047] A method for determining the test stress corresponding to the test load during the spring pressure treatment, including the following steps:

[0048] Step S1: Material selection; spring steel made of 60Si2MnA material is selected; spring steel wire made of 60Si2MnA material is measured to be 50mm, the middle diameter of the spring is 185mm, and the winding ratio

[0049] Step S2: Calculate the test load; set the test load as F s , The test stress of spring steel of different materials is τ s , Τ s According to calculation formula (1) or calculation formula (2); according to design requirements, the tensile strength of spring steel made of 60Si2MnA is 1570Mpa, and the yield strength of spring steel made of 60Si2MnA is 1375Mpa.

[0050] Calculation formula (1)τ s Tensile strength R according to design requirements m 70% of the lower limit is calculated and determined:

[0051] τ s =0.7σ b =0.7×1570=1099Mpa (1);

[0052] Or, the calculation formula (2)τ s 80% of the yield strength ...

Embodiment 2

[0062] A method for determining the test stress corresponding to the test load during the spring pressure treatment, including the following steps:

[0063] Step S1: Material selection; spring steel made of 60Si2CrA is selected; spring steel wire made of 60Si2CrA is measured to be 55mm, the middle diameter of the spring is 198mm, and the winding ratio

[0064] Step S2: Calculate the test load; set the test load as F s , The test stress of spring steel of different materials is τ s , Τ s According to calculation formula (1) or calculation formula (2); according to design requirements, the tensile strength of spring steel made of 60Si2CrA is 1765Mpa, and the yield strength of spring steel made of 60Si2CrA is 1570Mpa.

[0065] Calculation formula (1)τ s Tensile strength R according to design requirements m 70% of the lower limit is calculated and determined:

[0066] τ s =0.7σ b =0.7×1765=1235.5Mpa (1);

[0067] Or, the calculation formula (2)τ s 80% of the yield strength required by spri...

Embodiment 3

[0077] A method for determining the test stress corresponding to the test load during the spring pressure treatment, including the following steps:

[0078] Step S1: Material selection; use spring steel made of 60Si2CrVA material; measure the spring steel wire made of 60Si2CrVA material to be 55mm, the middle diameter of the spring is 196mm, and the winding ratio

[0079] Step S2: Calculate the test load; set the test load as F s , The test stress of spring steel of different materials is τ s , Τ s According to calculation formula (1) or calculation formula (2); according to design requirements, the tensile strength of spring steel made of 60Si2CrVA is 1860Mpa, and the yield strength of spring steel made of 60Si2CrVA is 1665Mpa.

[0080] Calculation formula (1)τ s Tensile strength R according to design requirements m 70% of the lower limit is calculated and determined:

[0081] τ s =0.7σ b =0.7×1860=1302Mpa (1);

[0082] Or, the calculation formula (2)τ s 80% of the yield strength requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Middle diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com