Reusable universal radio frequency device test fixture

A technology of radio frequency devices and test fixtures, which is applied to parts, instruments, and measuring devices of electrical measuring instruments. It can solve the problems of complex testing process, poor compatibility of test fixtures, and high cost, and achieve a wide range of applications. No effect of mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

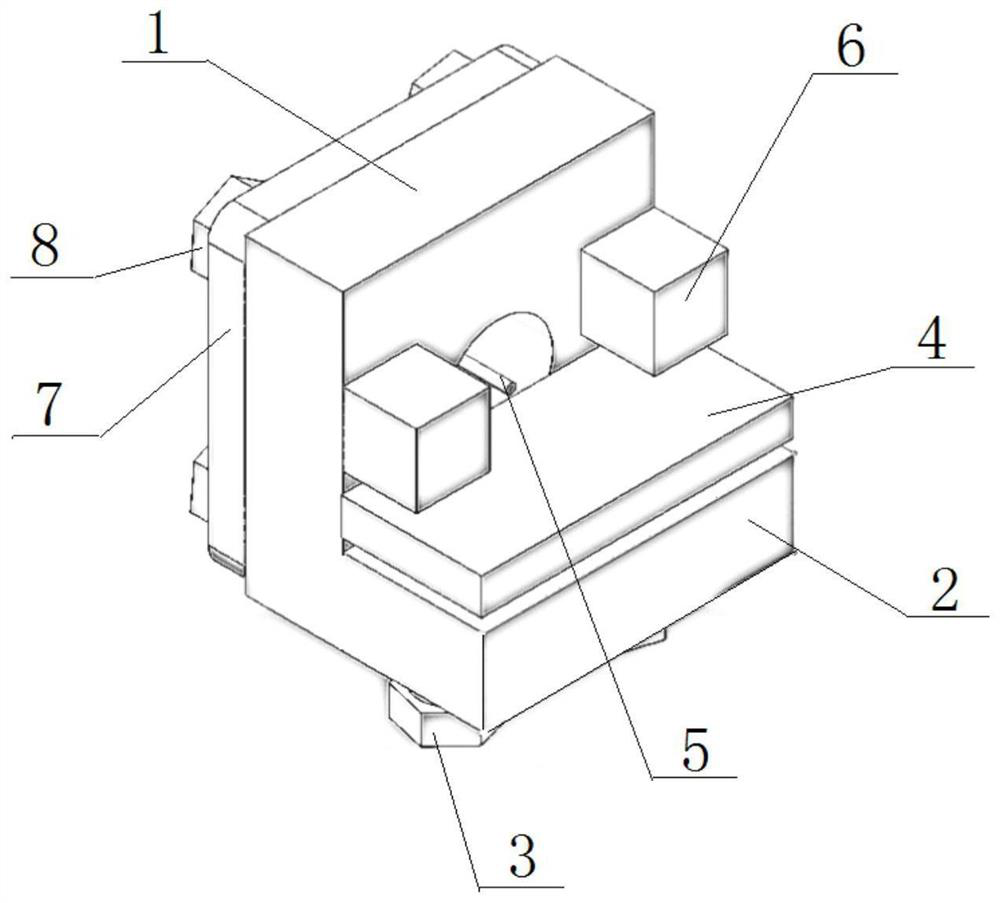

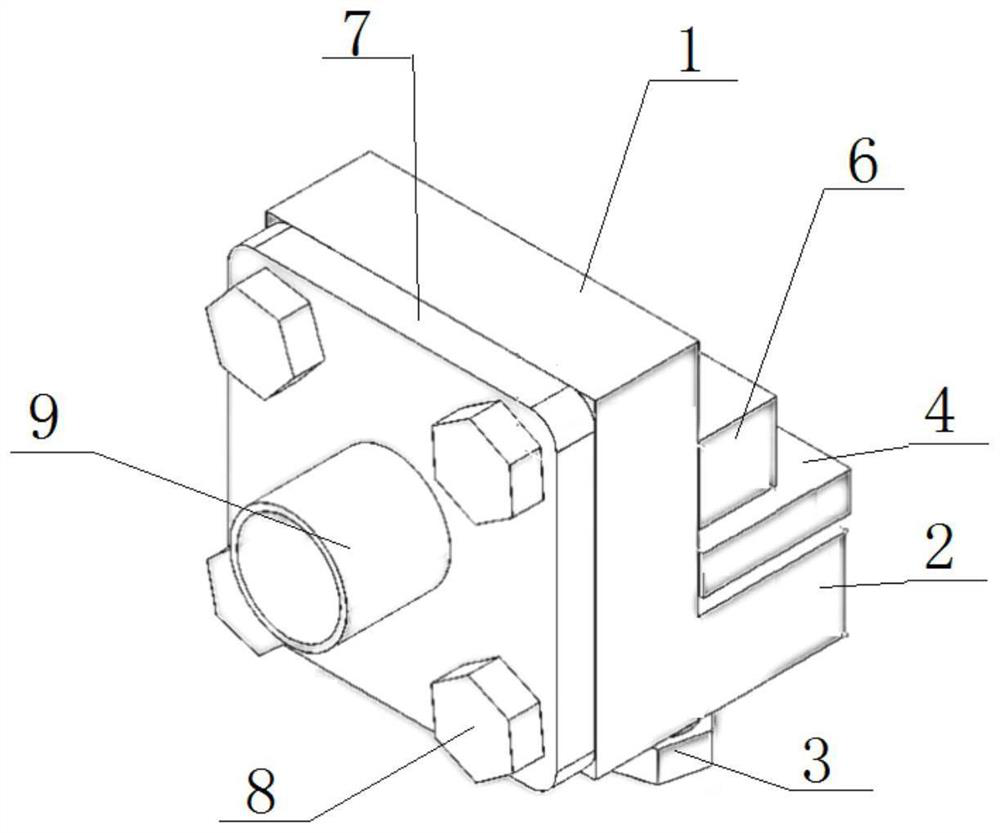

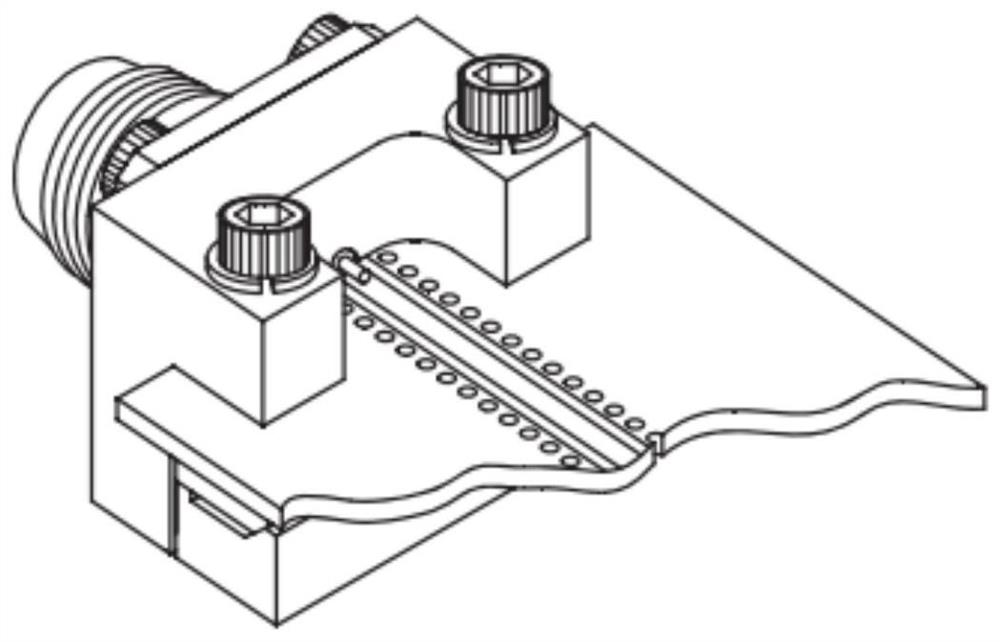

[0028] Such as Figure 1 to Figure 2 As shown, the reusable universal radio frequency device test fixture of the present invention includes a single-ended SMA connector connected to the radio frequency device to be tested, and a base for fixing the single-ended SMA connector, the base includes an integrally processed vertical plate 1, and The base plate 2 installed perpendicular to the bottom of the vertical plate 1; the bottom surface of the base plate 2 is equipped with a number of through-setting adjusting bolts 3, and the top of the adjusting bolts 3 can lift up an adjusting plate 4; the center of the vertical plate 1 is provided with a through hole, along which the The single-ended SMA connector set in the direction of the hole is fixed on the back of the vertical plate 1, and the single-ended SMA connector includes a tubular shell 9, which is fixed on the vertical plate 1 via the positioning plate 7, and the inside of the tubular shell 9 is installed with the radio freque...

Embodiment 2

[0040] As an improvement of the present invention, it is possible to test and replace the single-ended SMA connectors as needed.

[0041] The base plate 2 has two adjusting bolts 3 for screwing into the base plate 2 to control the height of the adjusting plate 4 .

[0042] The material of the regulating plate 4 is a metal material with good electrical conductivity, such as copper, aluminum alloy, stainless steel and other metals.

[0043] After the radio frequency device to be tested is put into the card slot of the base, the metal core 5 in the center of the single-ended SMA connector, the radio frequency device to be tested, the adjustment plate 4, and the adjustment bolt 3 are in sequence from top to bottom.

[0044] There are two adjusting bolts 3 and the number of adjusting bolts 3 .

[0045] The measurement fixture includes a single-ended SMA connector and a coplanar waveguide (CPW) structure base. The base is followed by an adjustment plate 4, a limit block 6, and a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com