Direct-current ore-smelting electric furnace with variable loop

A submerged heat electric furnace and circuit technology, which is applied in the direction of electric furnace heating, furnace, furnace components, etc., can solve the problems of severe anode heating at the end, fast consumption of anode electrodes, and large heat generation, so as to prevent accumulation and agglomeration and speed up Thermal fusion, the effect of increasing the degree of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

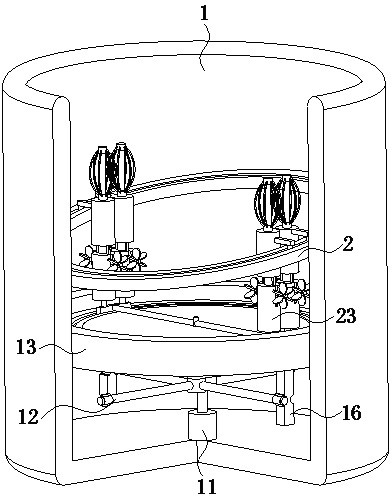

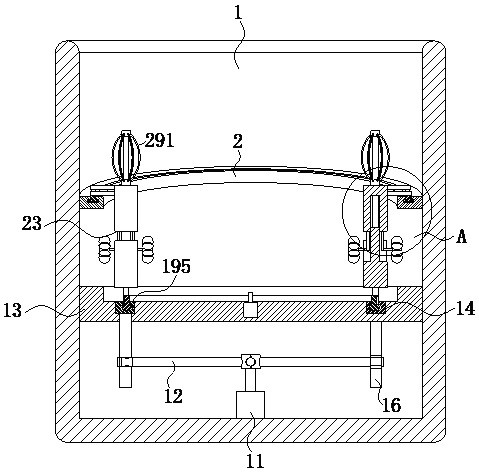

[0029] use Figure 1-Figure 5 A DC submerged arc furnace with a variable circuit according to an embodiment of the present invention is described as follows.

[0030] Such as Figure 1-Figure 5 As shown, a DC submerged arc furnace with a variable circuit according to the present invention includes a furnace body 1; the inner surface of the furnace body 1 is fixedly connected with a servo motor 11 at the bottom of the furnace body 1, and the servo motor 11 is connected to the furnace body through a wire. The controller is electrically connected; the drive shaft of the servo motor 11 is fixedly connected with conductive columns 12 arranged uniformly, and the number of conductive columns 12 is four; the electrodes of the left and right conductive columns 12 are negative poles and positive poles respectively; the front and rear conductive columns The electrodes of 12 are negative pole and positive pole respectively; The said conducting column 12 of each positive pole is all elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com