Density-controllable hail preparation method and extrusion device for hail manufacturing

A technology of an extrusion device and a manufacturing method is applied in the field of devices for making artificial hailstones with controllable density, and can solve the problems of not meeting the density requirements of natural hailstones, lack of means for preparing artificial hailstones with controllable density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

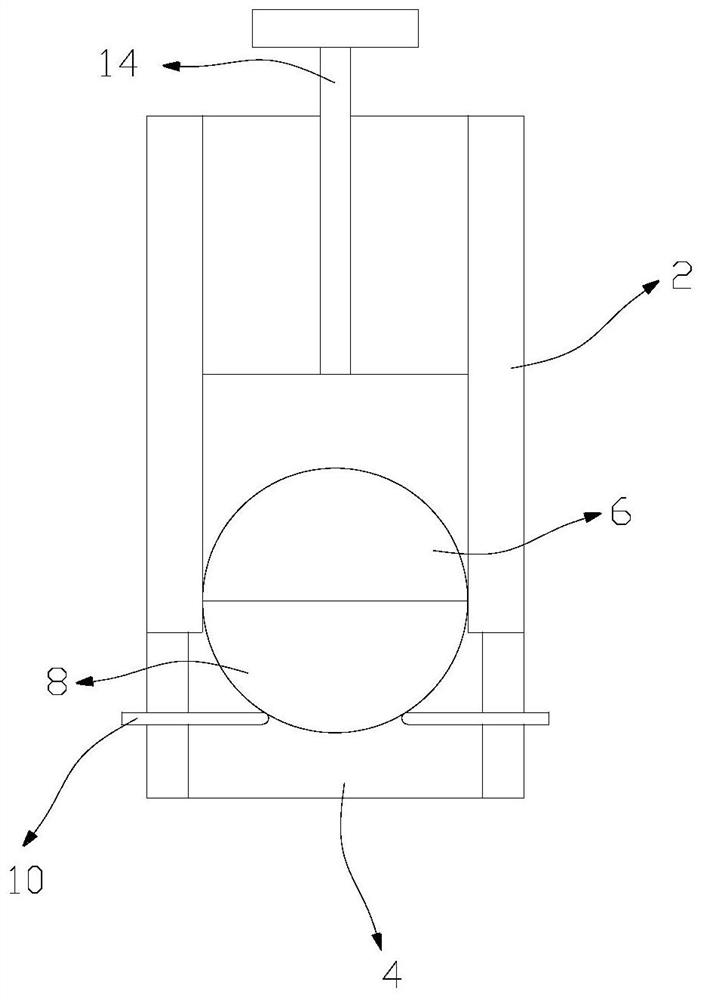

[0031] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

[0032] Such as figure 1 As shown, the method for preparing controllable density hail of the present invention is characterized in that it comprises the following steps:

[0033] S1, ice making;

[0034] S2. Break the ice cubes into crushed ice with an ice crusher;

[0035] S3. Weigh the above-mentioned crushed ice with a mass of M (unit: g) into the squeezing device;

[0036] S4. The crushed ice is squeezed by the squeezing device to compress its volume to L (unit: cm 3 ), where M: L=0.6~0.9 (unit g / cm 3 );

[0037] S5. Take out the crushed ice and spray at least one layer of water mist on the surface;

[0038] S6. Store the crushed ice in a frozen state.

[0039] According to the present invention, crushed ice is extruded to form hail with a density of 0.6-0.9, and the hail produced by this method will not crack or break during high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com