A kind of external wall insulation block and its manufacturing method

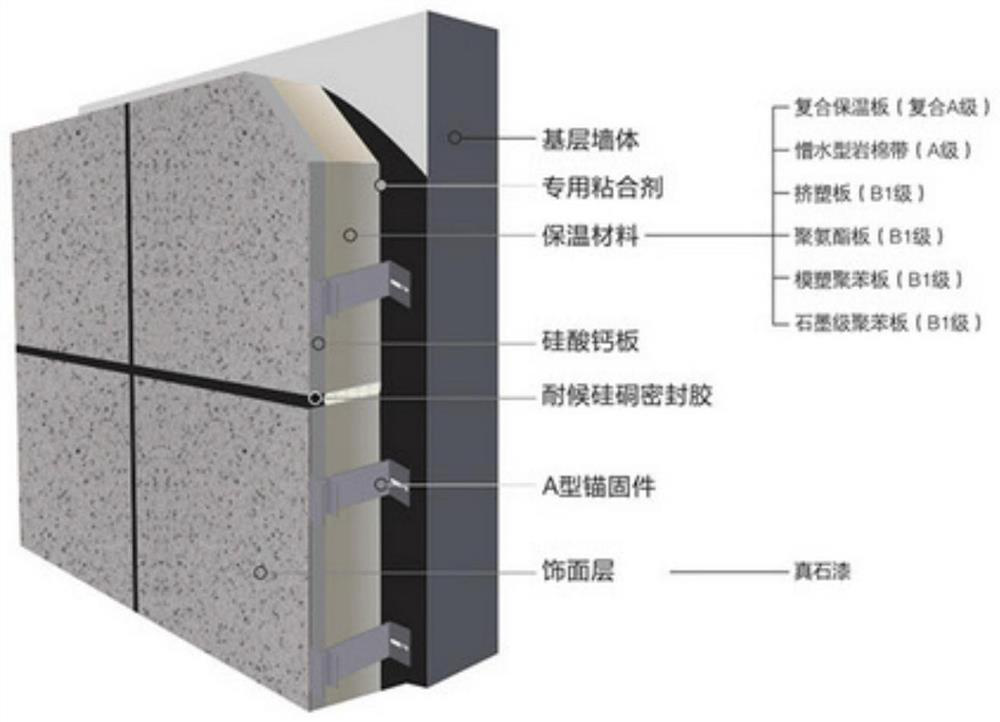

A technology for external wall insulation and thermal insulation blocks, applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problems of slow progress and complicated construction technology, and achieve the effects of improved construction progress, simplified construction technology, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

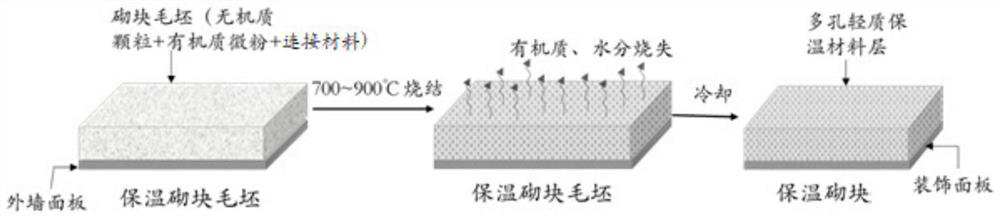

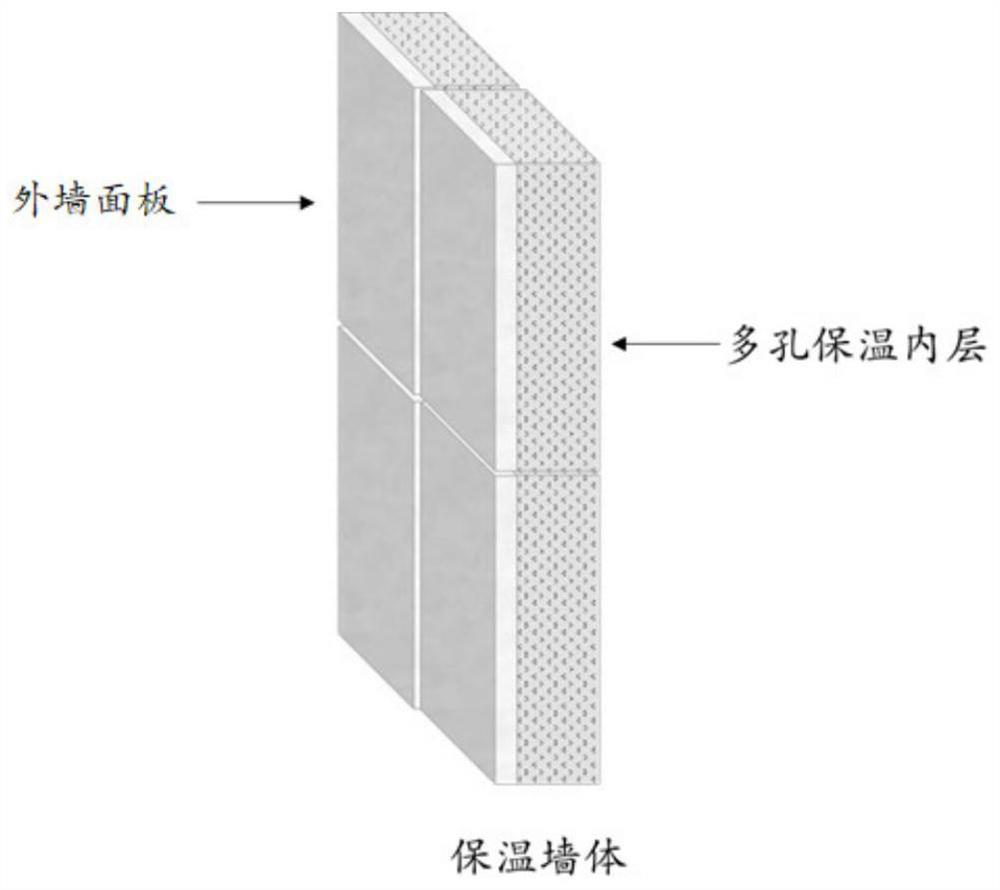

[0065] refer to figure 1 , place the decorative panel granite slab under the upper mold, the upper mold is a pressing plate, and the lower mold is a frame structure surrounded by side splints, and the ceramic grinding sludge microparticles (wherein the content of silicon dioxide is 70%, and the average particle size is 30μm ), straw powder (average particle size 10μm) and connecting material (mixture powder of kaolin, quartz, feldspar and a small amount of potassium oxide, average particle size 5μm) according to the dosage of 1500kg, 400kg, 95kg per cubic meter (of which kaolin 40kg, quartz 30kg, Feldspar 20kg and Potassium Oxide 5kg) are mixed in an amount to obtain mixed powder, and the mixed powder is loaded in the cavity surrounded by the bottom support plate of the granite panel and the frame structure of the lower mold, and the upper mold pressing plate vibrates the mixed powder. The powder is compacted and formed, the vibration frequency is 45 Hz, and the downward press...

Embodiment 2

[0068] Lay the decorative panel porcelain panel under the upper mold; mix the glass grinding sludge microparticles (the content of silicon dioxide is 90%, the average particle size is 20 μm), straw powder (average particle size is 10 μm) and mix them into the connecting material (average particle size 1 μm), mixed powder is obtained after mixing, wherein each cubic meter contains 1600kg of glass grinding sludge particles, 800kg of straw powder, 200kg of connecting materials (containing 100kg of kaolin, 80kg of quartz, 18kg of feldspar and 2kg of potassium oxide) , load the mixed powder in the cavity surrounded by the support plate at the bottom of the tile panel and the frame structure of the lower mold, and the upper mold press plate vibrates to compact the mixed powder, with a vibration frequency of 45 Hz, and apply it to the mixed powder The upward and downward pressure is 60 kN, so that the tile panel and the block body are combined to obtain a molding blank.

[0069] The ab...

Embodiment 3

[0071] Lay the decorative panel granite slab under the upper mold, the upper mold is a pressing plate, and the lower mold is a frame structure surrounded by side splints, ceramic grinding tailings powder (the content of silicon dioxide is 80%, the average particle size is 100μm), Straw powder (average particle size 10μm) and connecting material (mixture powder of kaolin, quartz, feldspar and a small amount of potassium oxide, average particle size 5μm) are respectively 2000kg, 900kg, 120kg per cubic meter (of which kaolin 60kg, quartz 30kg, feldspar 25kg and a small amount of potassium oxide (5kg) are mixed to obtain mixed powder, which is loaded in the cavity surrounded by the bottom support plate of the granite panel and the frame structure of the lower mold, and the upper mold pressing plate vibrates the mixed powder The material is compacted and formed, the vibration frequency is 60 Hz, and the downward pressure applied to the mixed powder is 90 kN, so that the granite pane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com