Heat shield device for single crystal production furnace, control method and single crystal production furnace

A single crystal, single crystal silicon technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of uneven temperature gradient, achieve radial temperature gradient optimization, high heat reflection efficiency, longitudinal temperature gradient Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

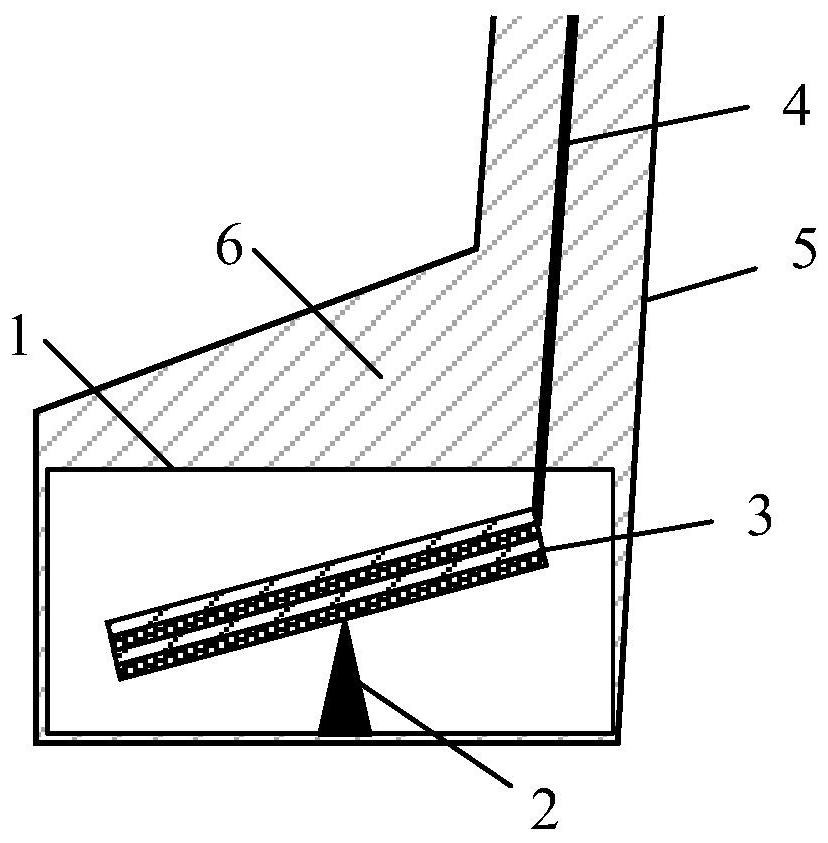

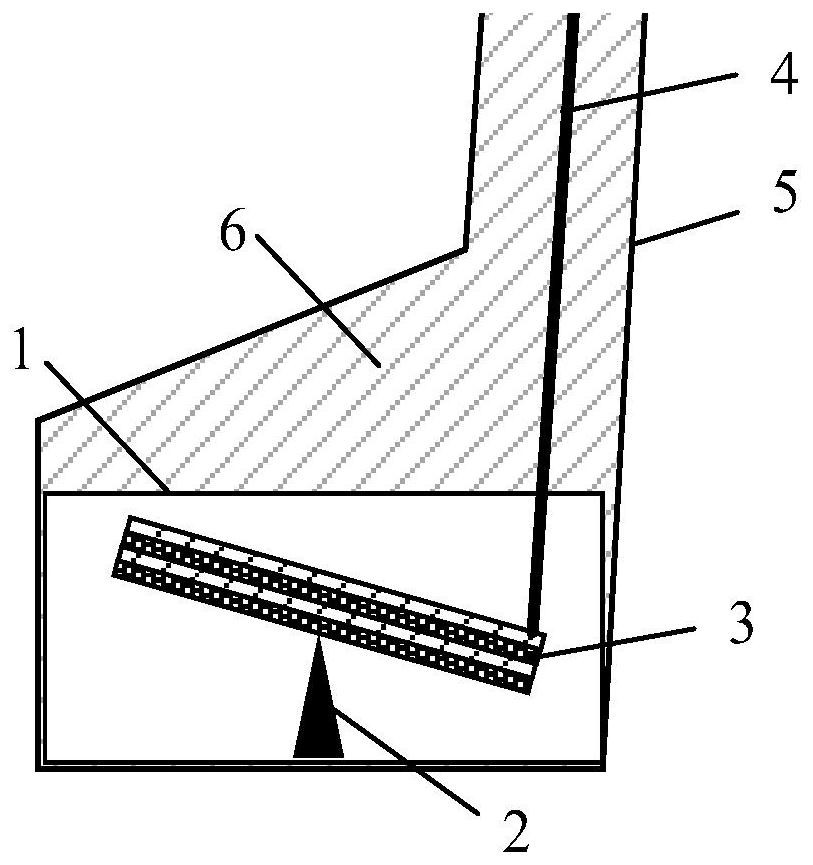

[0047] refer to figure 1 , figure 2 and Figure 8 , a heat shield device for a single crystal production furnace, the heat shield device 16 is used to be arranged on the upper part of the melt crucible 15 of a single crystal silicon growth furnace, and the heat shield device 16 includes a housing 1, a support member 2, and a heat shield 3 and the direction control assembly 4, the support 2 and the heat shield 3 are set in the housing 1, one end of the support is fixedly connected to the inner wall of the housing, the direction control assembly 4 is connected to the heat insulation board 3, and the support 2 is used as The fulcrum of the heat shield 3 cooperates with the direction control assembly 4 to control the relative rotation between the heat shield 3 and the housing 1, the rotatable angle of the heat shield 3 faces the cylindrical surface of the monocrystalline silicon 14, and the bottom of the housing 1 The surface is intended to be towards the inside of the melt cru...

Embodiment 2

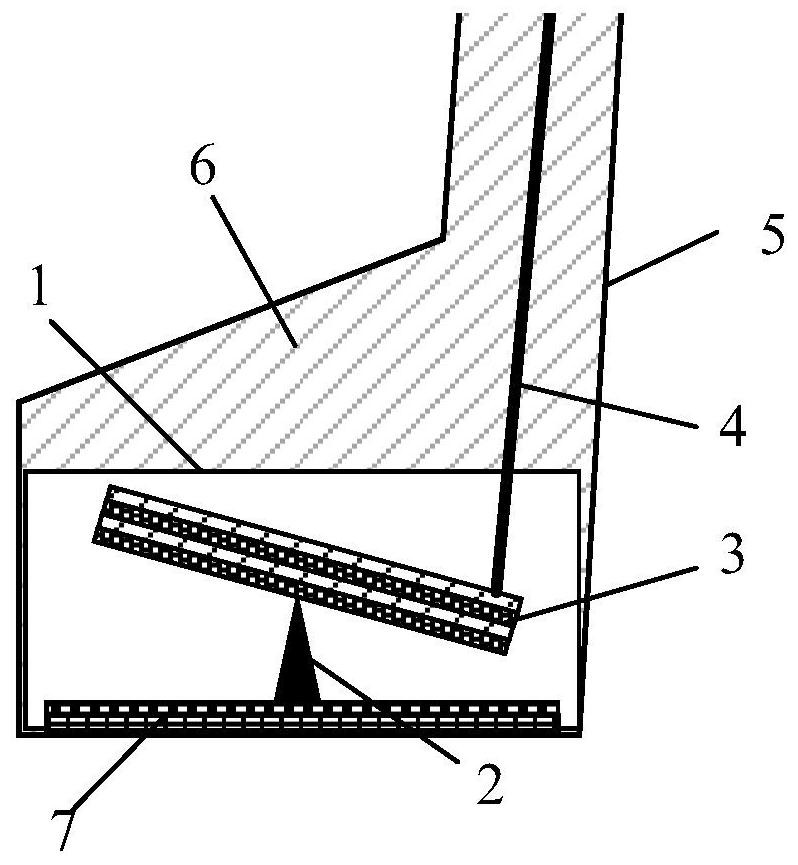

[0061] The difference between this embodiment and Embodiment 1 is that a heat absorbing plate is added. Such as image 3 As shown, a heat shield device for a single crystal production furnace, the heat shield device 16 is used to be arranged on the upper part of the melt crucible 15 of a single crystal silicon growth furnace, and the heat shield device 16 includes a housing 1, a support member 2, a partition The heat plate 3 and the direction control assembly 4, the support 2 and the heat shield 3 are arranged in the casing 1, one end of the support is fixedly connected with the inner wall of the casing, the direction control assembly 4 is connected with the heat insulation plate 3, and the support 2 is used As the fulcrum of the heat shield 3 and cooperate with the direction control assembly 4 to control the relative rotation between the heat shield 3 and the housing 1, the rotatable angle of the heat shield 3 faces the cylindrical surface of the monocrystalline silicon 14, a...

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 lies in that the number of support members 2 and their positions, as well as the position of the direction control assembly in this embodiment are different. In this embodiment, the structure of the housing 1 is an annular structure with a cavity inside, the shape of the heat shield 3 is a fan ring, and the number of the heat shield 3 is 2, and the central angle of the sector of the two heat shields is Both are 180 degrees, set in the shell 1, when the two heat shields are in a horizontal state, they are located on the same horizontal plane and there is no overlapping area between them, a support that matches a single heat shield 3 There are 2, ie a total of 4 supports. The point where one end of the support member 2 contacts the heat insulation board 3 is the fulcrum of the heat insulation board 3 , and the contact point can be on the upper surface or the lower surface of the heat insulation board 3 . Two support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com