Method for improving biogas production performance of anaerobic fermentation of wheat straw through low-temperature freeze-thawing pretreatment

A wheat straw, anaerobic fermentation technology, applied in the direction of fermentation, waste fuel, etc., can solve the problems of limited effect of straw structure change, increased equipment purchase cost, power consumption, etc., to improve the efficiency of the hydrolysis step, shorten the anaerobic fermentation period, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

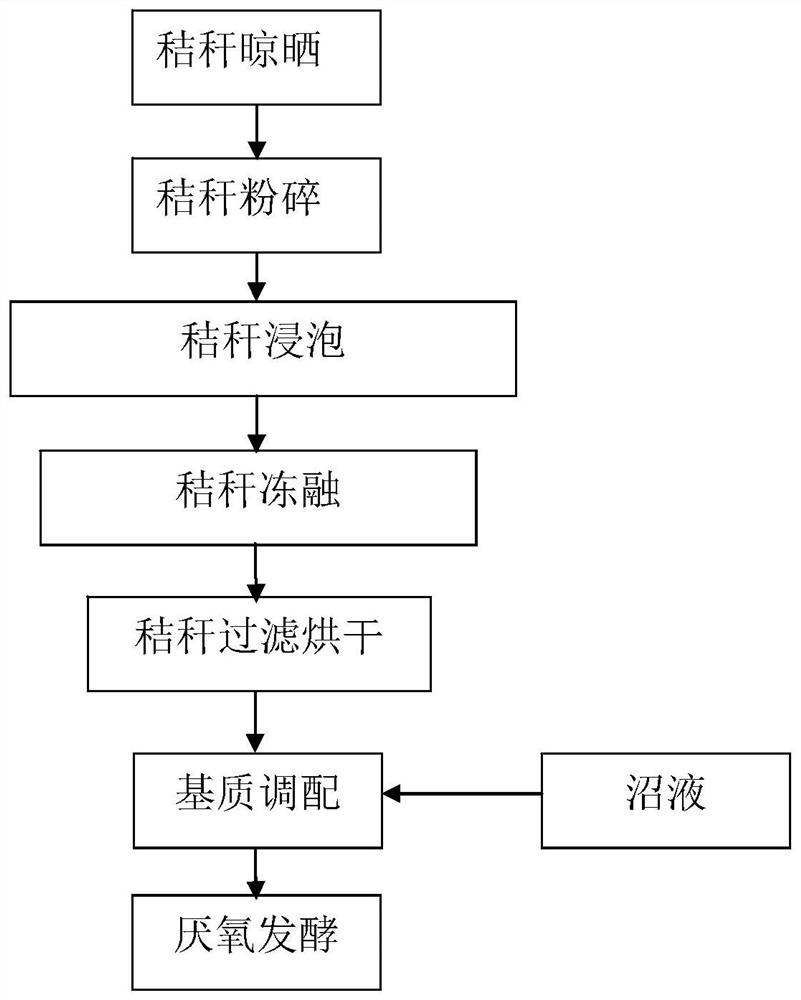

[0029] A method for low-temperature freeze-thaw pretreatment to improve the biogas production performance of wheat straw anaerobic fermentation, such as figure 1 shown, including the following steps:

[0030] Step 1, freeze-thaw pretreatment:

[0031] The dried wheat straw was crushed to 20 mesh, and dried at 55°C until constant weight. Take 10 g of dried wheat straw and place it in a ziplock bag, add deionized water, adjust the solid-to-liquid ratio to a mass ratio of 1:8, and mix thoroughly to obtain a mixture that is soaked at room temperature for 8 hours. Subsequently, the mixture was frozen in a -20°C refrigerator, taken out after 12 hours, and thawed naturally at room temperature for 8 hours. The wheat straw is filtered out, placed in an oven at 55° C. and baked to constant weight to obtain pretreated wheat straw.

[0032] Step 2, anaerobic fermentation to produce biogas:

[0033] Put the pretreated wheat straw into a 500ml fermenter, add the biogas slurry of the ino...

Embodiment 2

[0036] A method of low-temperature freeze-thaw pretreatment to improve the performance of biogas production by anaerobic fermentation of wheat straw is basically the same as the method in Example 1, except that the freezing time in step 1 is changed to 24 hours, 48 hours, and 96 hours respectively.

[0037] The efficiency of straw gas production during 24-hour freezing time was: the maximum gas production was 165.63mL / g, and the time to reach the maximum gas production was 27 days. The peak of gas production occurred on the 9th day, the biogas stagnation period was 7 days, and the entire fermentation system was stable.

[0038] The gas production efficiency of straw with 48-hour freezing time is: the maximum gas production is 164.35mL / g, and the time to reach the maximum gas production is 27 days. The peak of gas production occurred on the 9th day, the biogas stagnation period was 7 days, and the entire fermentation system was stable.

[0039] The gas production efficiency ...

Embodiment 3

[0041] A method for improving the performance of biogas production by anaerobic fermentation of wheat straw through low-temperature freeze-thaw pretreatment is basically the same as the method in Example 1, except that the freezing temperature in step 1 is changed to -10°C, -40°C, and -80°C respectively.

[0042] The gas production efficiency of straw at -10°C is: the gas production efficiency of straw at 12 hours of freezing time is: the maximum gas production is 161.66mL / g, and the time to reach the maximum gas production is 25 days. The peak of gas production occurred on the 9th day, the biogas stagnation period was 7 days, and the entire fermentation system was stable.

[0043] The gas production efficiency of straw at -40°C is: the gas production efficiency of straw for 12 hours of freezing time is: the maximum gas production is 163.83mL / g, and the time to reach the maximum gas production is 25 days. The peak of gas production occurred on the 9th day, the biogas stagnatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com