Photochromic polyester and preparation method and application thereof

A technology of photochromism and polyester, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, optics, etc., can solve the problems of poor mechanical properties, high price, low glass transition temperature, etc., and achieve high production efficiency, easy operation, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In some embodiments, the preparation method includes: reacting the first mixed reaction system at 160-260° C. for 2-6 hours to obtain an intermediate product.

[0056] In some embodiments, the preparation method includes: reacting the second mixed reaction system in a vacuum environment at 200-300°C for 1-8 hours to obtain a photochromic polyester, and the vacuum degree of the vacuum environment is 300Pa the following.

[0057] In some embodiments, the preparation method specifically includes: making components containing component A (ie, azobenzene compound), component B (ie, aromatic dibasic acid or its esterified product), component C (ie, the second fatty Dihydric alcohol), esterification or transesterification catalyst, react at 160-260°C for 2-6h to obtain intermediate product; then add polycondensation catalyst and react at 200-300°C for 1-8h under vacuum condition to obtain photochromic polymer ester.

[0058] Further, the preparation method of the photochromi...

Embodiment 1

[0101] Mix azobenzenediol (Formula 3), dimethyl terephthalate, and decanediol (the second fatty diol) in a molar ratio of 0.01:1:0.99, and then add the catalyst (tetrabutyl titanate Esters, based on dimethyl terephthalate is 0.2mol%) and catalyst (antimony trioxide, based on dimethyl terephthalate is 0.15mol%), join in the reactor, under nitrogen protection condition, be heated up to 160°C, react for 6h, vacuum degree is 60Pa, heat up to 200°C, react for 6h to obtain photochromic copolyester (structure as formula 4), its glass transition temperature is 26°C, tensile strength is 30MPa, elongation at break The elongation rate is 400%, the number of cycle stability is more than 100 times, and the photochromic response speed is 10 seconds.

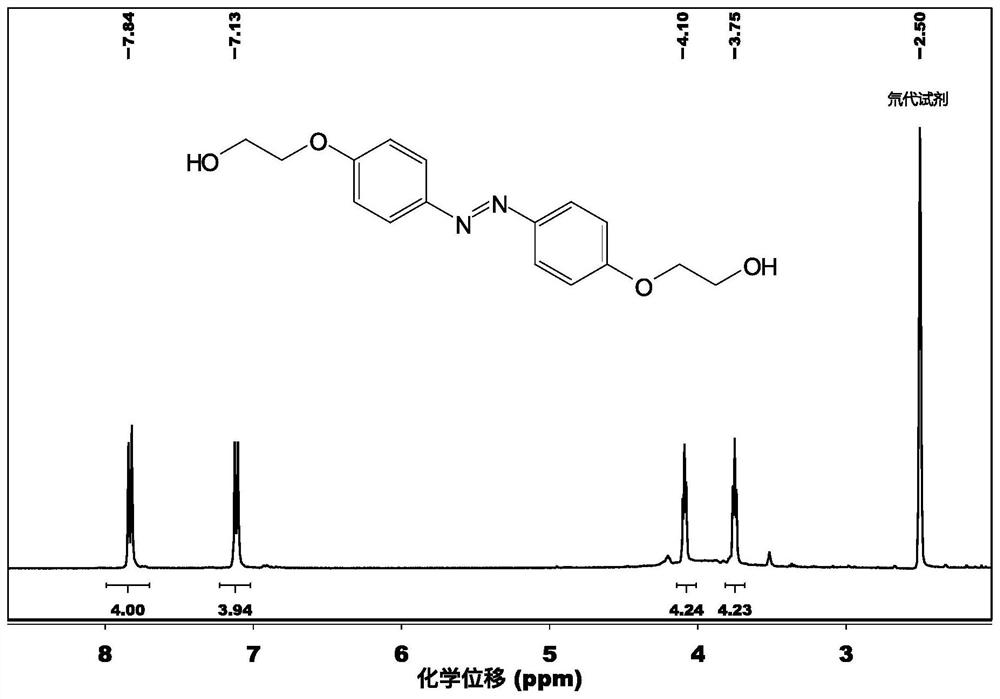

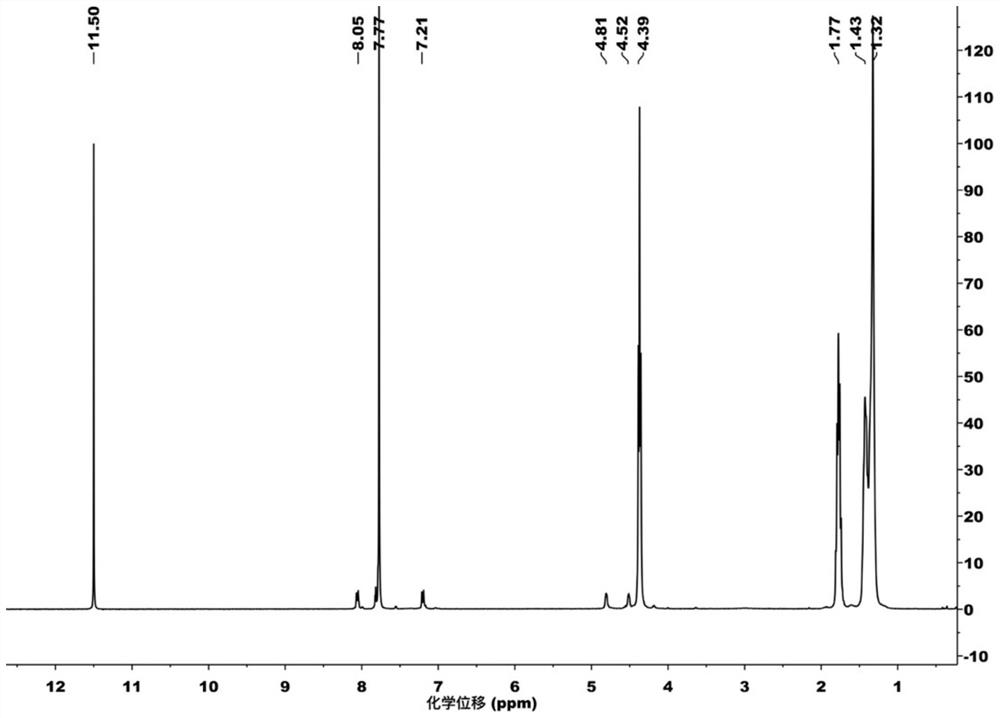

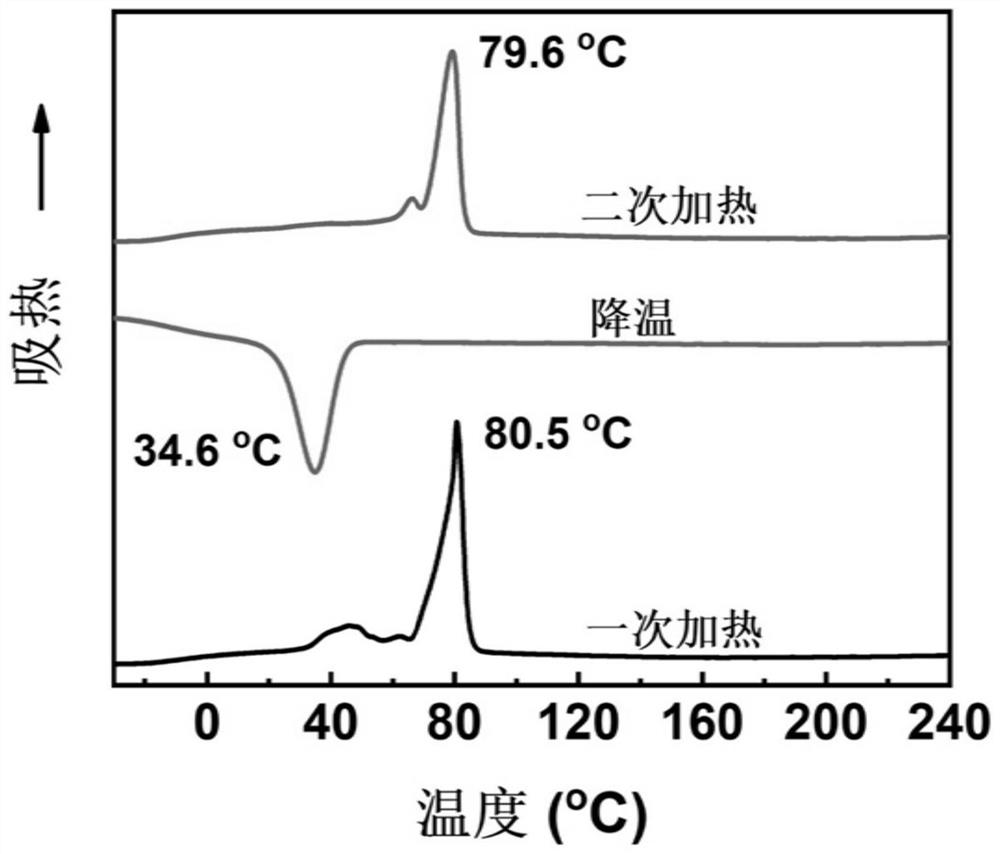

[0102] The 1HNMR spectrum of the azobenzenediol compound in the present embodiment is as follows figure 1 Shown, the 1HNMR spectrum of the finally obtained photochromic polyester please refer to figure 2 , please refer to the DSC curve of t...

Embodiment 2

[0105] Mix azobenzenediol (formula 3), dimethyl isophthalate, and decanediol (the second fatty diol) in a molar ratio of 0.05:1:0.95, and then add the catalyst (tetrabutyl titanate Esters, based on dimethyl isophthalate is 0.2mol%) and catalyst (antimony trioxide, based on dimethyl isophthalate is 0.1mol%), join in the reactor, under nitrogen protection condition, be heated up to 210°C, react for 3 hours, vacuum degree is 60Pa, heat up to 260°C, react for 4.0h to obtain photochromic polyester (structure as formula 5), its glass transition temperature is 25°C, tensile strength is 20MPa, elongation at break The elongation rate is 170%, the number of cycle stability is more than 100 times, and the photochromic response speed is 10 seconds.

[0106]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com