Vibration-damping anti-freezing fiber-reinforced mineral-based gelling reinforced roadbed filler and preparation method thereof

A technology of roadbed filler and fiber reinforcement, which is used in manufacturing tools, ceramic molding machines, etc., to improve the strength of roadbed, prolong service life, and improve three-dimensional performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

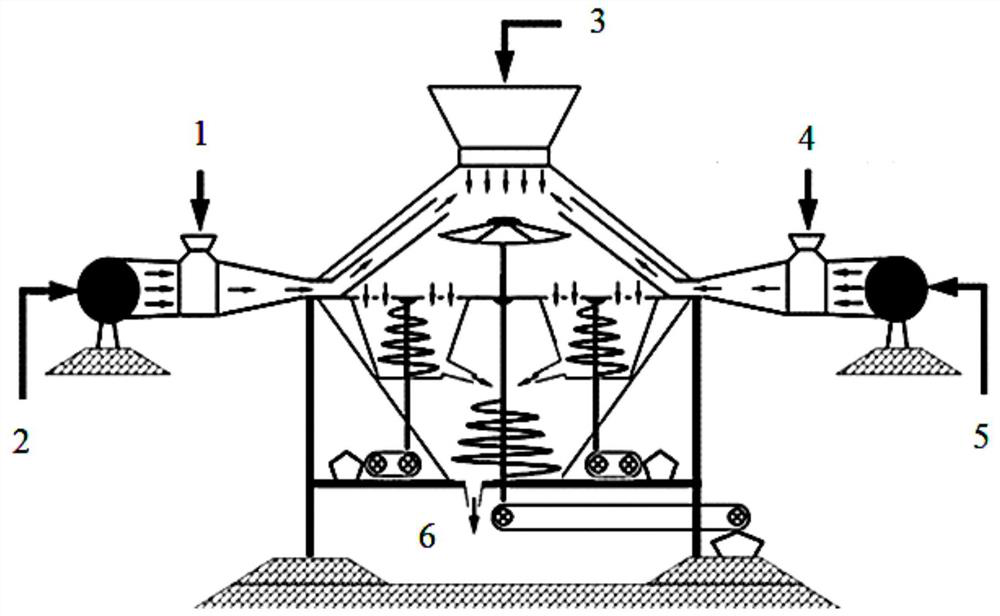

Method used

Image

Examples

Embodiment 1

[0024] A vibration-damping and antifreeze fiber-reinforced mineral-based cementitious reinforced roadbed filler, which consists of the following raw materials in parts by weight: 105 parts of roadbed filler, 4 parts of mineral-based cementitious materials, 15 parts of auxiliary materials and 8 parts of anti-crack fibers. The mineral-based cementitious material consists of the following raw materials in parts by weight: 10 parts of hornblende, 15 parts of potassium feldspar, 14 parts of ilmenite, 8 parts of corundum, 20 parts of kaolinite, 18 parts of biotite and 20 parts of pyroxene; the auxiliary materials are composed of the following raw materials in parts by weight, 95 parts of an alkaline activator, 0.8 parts of a surfactant, and 8 parts of a water reducer. The basic activator is a mixture of water glass and calcium chloride, and the weight ratio is 3:10. Described surfactant is triethanolamine. The dispersant is soybean lecithin dispersant. The water reducer is a polyc...

Embodiment 2

[0030] A vibration-damping-antifreeze fiber-reinforced mineral-based cementitious reinforced roadbed filler. The raw materials are composed of the following raw materials in parts by weight: 85 parts of roadbed filler, 1 part of mineral-based cementitious material, 9 parts of auxiliary materials and 0.5 parts of anti-crack fiber The mineral-based cementitious material consists of the following raw materials in parts by weight: 5 parts of hornblende, 7 parts of potassium feldspar, 9 parts of ilmenite, 4 parts of corundum, 12 parts of kaolinite, biotite 10 parts and 14 parts of pyroxene; the auxiliary materials are composed of the following raw materials in parts by weight, 85 parts of alkaline activator, 0.45 parts of surfactant, and 2 parts of water reducing agent. Described alkaline activator is the mixture of water glass and calcium chloride, and the weight ratio is 3:5. Described surfactant is triethanolamine. Described dispersant is sodium carboxymethyl cellulose. The wa...

Embodiment 3

[0032] A vibration-reducing-antifreeze fiber-reinforced mineral-based cementitious reinforced roadbed filler. The raw materials are composed of the following raw materials in parts by weight: 100 parts of roadbed filler, 3 parts of mineral-based cementitious materials, 12 parts of auxiliary materials and 5 parts of anti-crack fiber The mineral-based cementitious material consists of the following raw materials in parts by weight: 8 parts of hornblende, 12 parts of potassium feldspar, 12 parts of ilmenite, 6 parts of corundum, 16 parts of kaolinite, biotite 15 parts and 17 parts of pyroxene; the auxiliary materials are composed of the following raw materials in parts by weight, 90 parts of alkaline activator, 0.70 part of surfactant, and 6 parts of water reducer. Described alkaline activator is the mixture of water glass and calcium chloride, and the weight ratio is 3:8. Described surfactant is triethanolamine. The dispersant is soybean lecithin dispersant and sodium carboxyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Initial setting time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com