A method for detecting the leak rate performance of a silicon carbide composite material circular pipe

A composite material and detection method technology, which is applied in the direction of detecting the appearance of fluid at the leak point, testing the fluid tightness, and using liquid/vacuum for liquid tightness measurement, etc., to achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

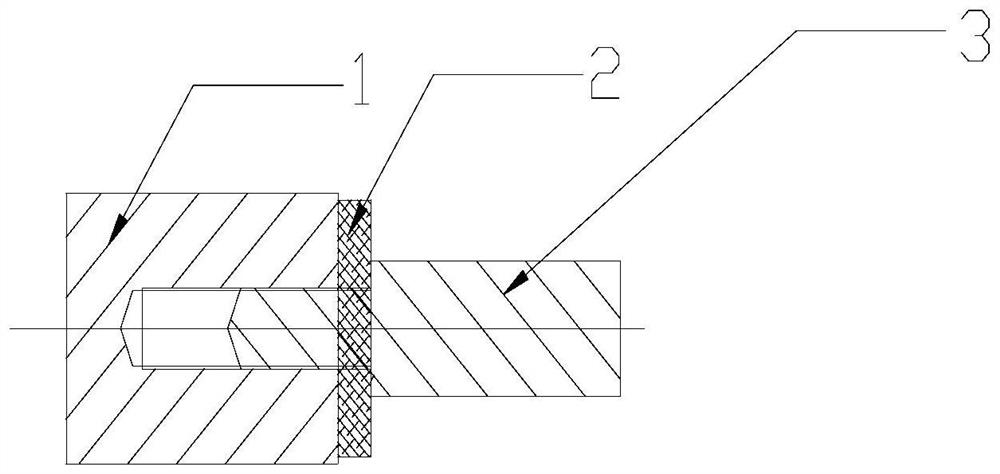

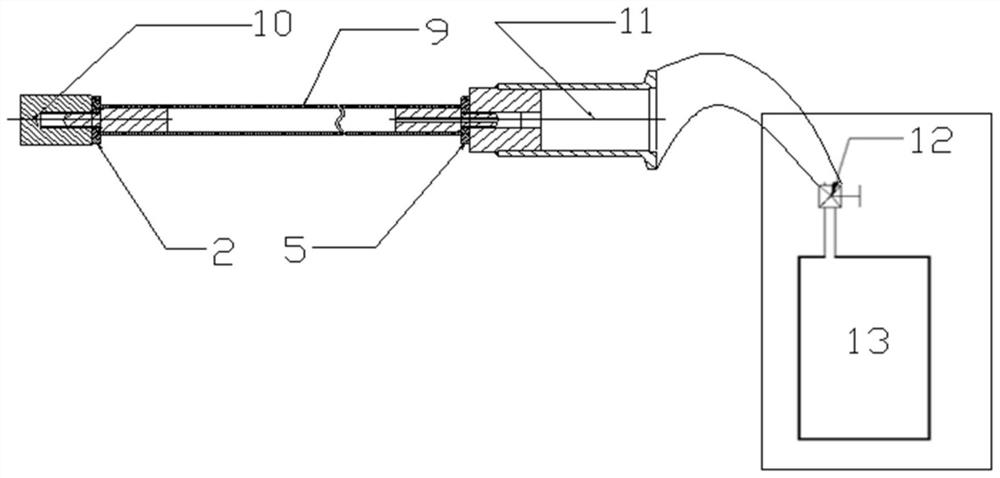

[0028] The silicon carbide round tube becomes a thin-walled long tube with an inner diameter of 10mm, an outer diameter of 12mm, and a total length of 100mm to 2000mm. During the development process, the outer diameter surface is uneven and the end surface has pores. The silicon carbide tube cannot be damaged during detection, and it is necessary to detect the leak rate of the silicon carbide tube when the sealing surface of the silicon carbide tube has pores and the surface is uneven, which greatly increases the difficulty of detection.

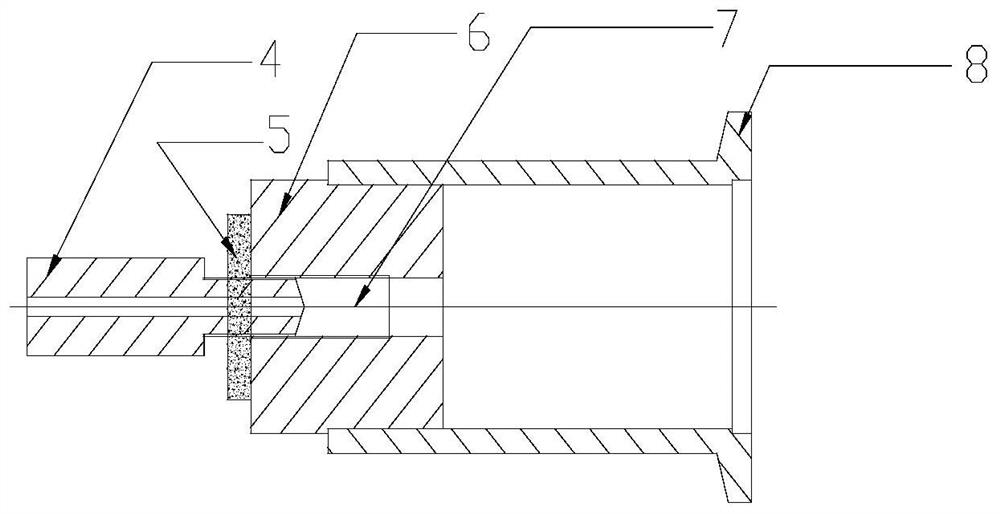

[0029] In order to overcome the above-mentioned technical solution, this embodiment adopts a helium mass spectrometer, a specially designed mold, and an assembly sealing treatment method to overcome the inherent defects of the silicon carbide tube, and will not cause damage to the silicon carbide tube during installation and testing. The special mandrel fits well with the silicon carbide round tube, one end is designed to be fully sealed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com