Novel hydraulic edge folding device

A hemming device and hydraulic technology, which is applied in the field of new hydraulic hemming devices, can solve problems such as the inability to form an all-inclusive hemming structure and the failure of a hemming machine to bend, so as to improve the range of hemming processing, ensure accuracy, and improve The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

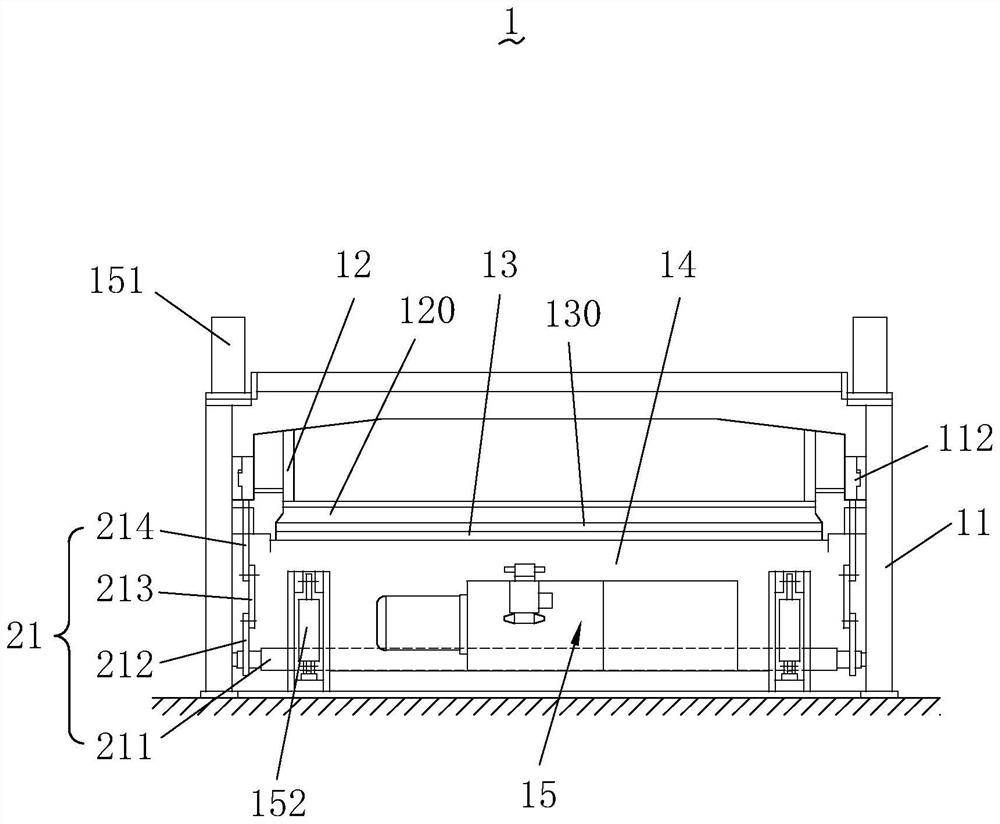

[0034] see figure 1 , figure 2 , Figure 4 and Figure 5 , the new hydraulic hemming device 1 includes a bed 11 , an upper knife rest 12 , a lower knife rest 13 , a folding knife plate 14 and a hydraulic drive assembly 15 .

[0035] The bed 11 is welded together by the left side plate, the right side plate, the lower tool rest 13 , the bottom frame, etc. to form a workbench, and the lower knife 130 is fixedly installed on the lower tool rest 13 .

[0036] The upper knife rest 12 is installed on the lifting sliders 112 on both sides of the bed 11 relative to the lower knife rest 13, so that the upper knife rest 12 can move up and down relative to the lower knife rest 13, and the upper knife 120 is fixedly installed on the The upper knife rest 12.

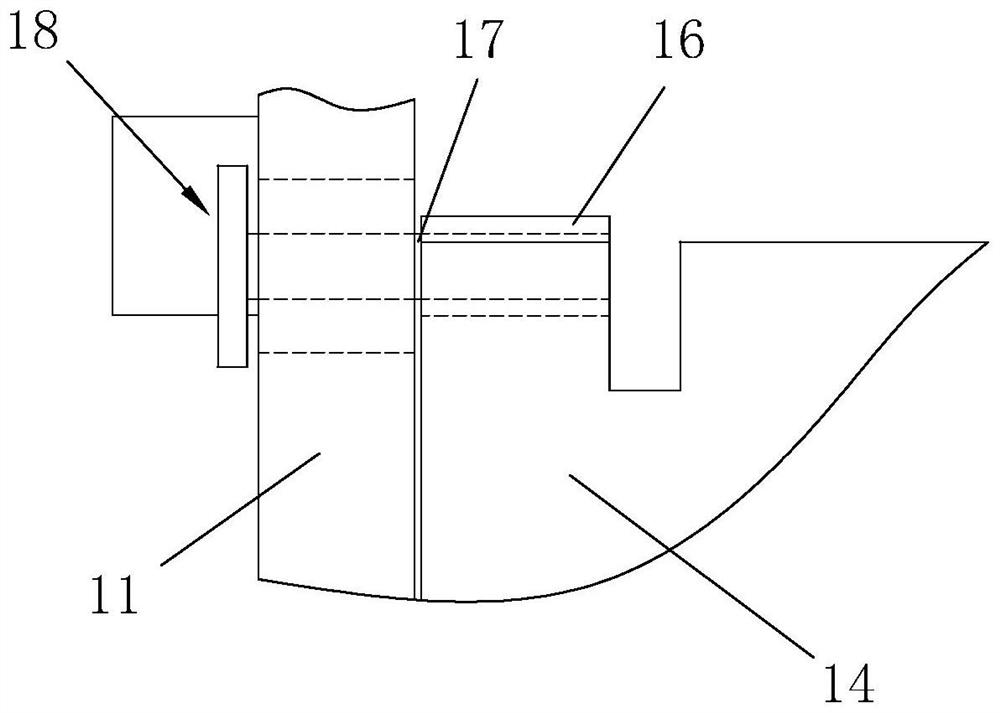

[0037] Both ends of the top of the jackknife plate 14 are rotatably mounted on the bed 11, and the jackknife plate 14 is arranged on the front of the lower knife rest 13, and the jackknife 140 is fixedly installed relative to t...

Embodiment 2

[0043] Based on the first embodiment, this embodiment further discloses the hydraulic drive assembly.

[0044] see figure 1 , Figure 7, the hydraulic drive assembly 15 in this embodiment includes a platen cylinder 151, a folding plate cylinder 152 and a hydraulic system. The ejector rod is connected to the lifting slider 112, and the two folding plate oil cylinders 152 are hinged to the bottom ends of the bed 11, and the ejector rods of the folding plate oil cylinders 152 are hinged to the folding knife plate 14. The hydraulic system drives the pressing plate oil cylinder 151 and folding plate oil cylinder 152 .

[0045] The hydraulic system described in this embodiment is as Figure 7 As shown, it includes oil tank 01, oil strainer 02, oil pump 03, coupling, motor 04, oil pressure gauge 05, overflow valve 06, electromagnetic reversing valve one 07, electromagnetic reversing valve two 08 and sequence valve 09. The control mode of described hydraulic system is as follows:...

Embodiment 3

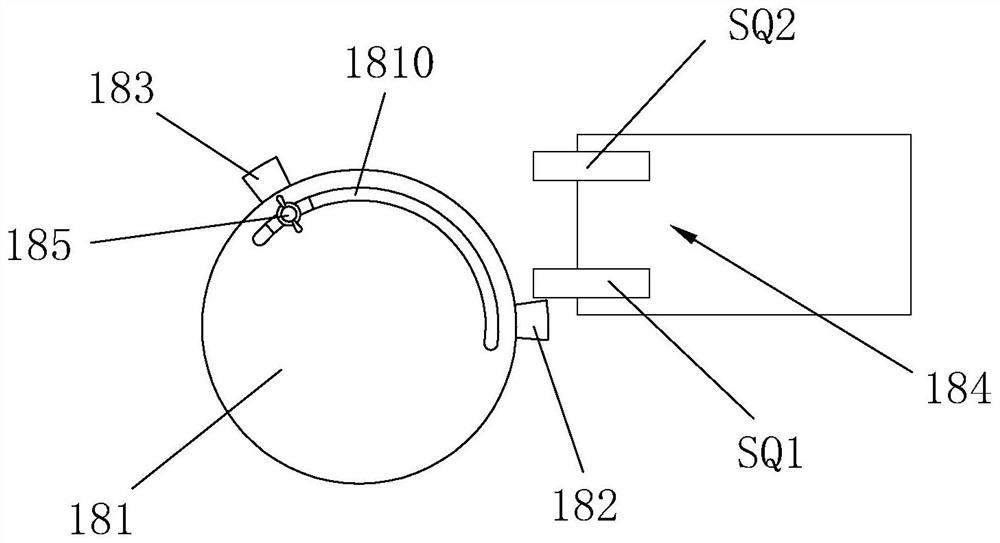

[0051] see figure 2 and image 3 , based on Embodiment 1 or Embodiment 2, the new hydraulic hemming device 1 of this embodiment further includes a folding plate limit adjustment assembly 18 to realize the adjustment and limit of the bending angle of the folding knife plate.

[0052] Specifically, the flap limit adjustment assembly 18 of this embodiment includes an index plate 181, a fixed block 182, a movable block 183 and an angle limit switch 184, and the index plate 181 is fixedly installed on the hinge At the end of the main shaft 17, the index plate 181 rotates with the rotation of the hinge main shaft 17. The fixed block 182 is fixed on the periphery of the index plate 181, and the surface of the index plate 181 is provided with Adjustment slot 1810 with angle scale, the movable block 183 is fixedly installed on the periphery of the index plate 181 through the adjustment slot 1810 through the locking bolt 185, and the angle limit switch 184 can touch the movable The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com