Fully automatic pipe fitting bending machine

A pipe bending and fully automatic technology, applied in the field of automation, can solve problems such as unsuitability for mass production and large errors, and achieve the effects of saving manpower, high speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

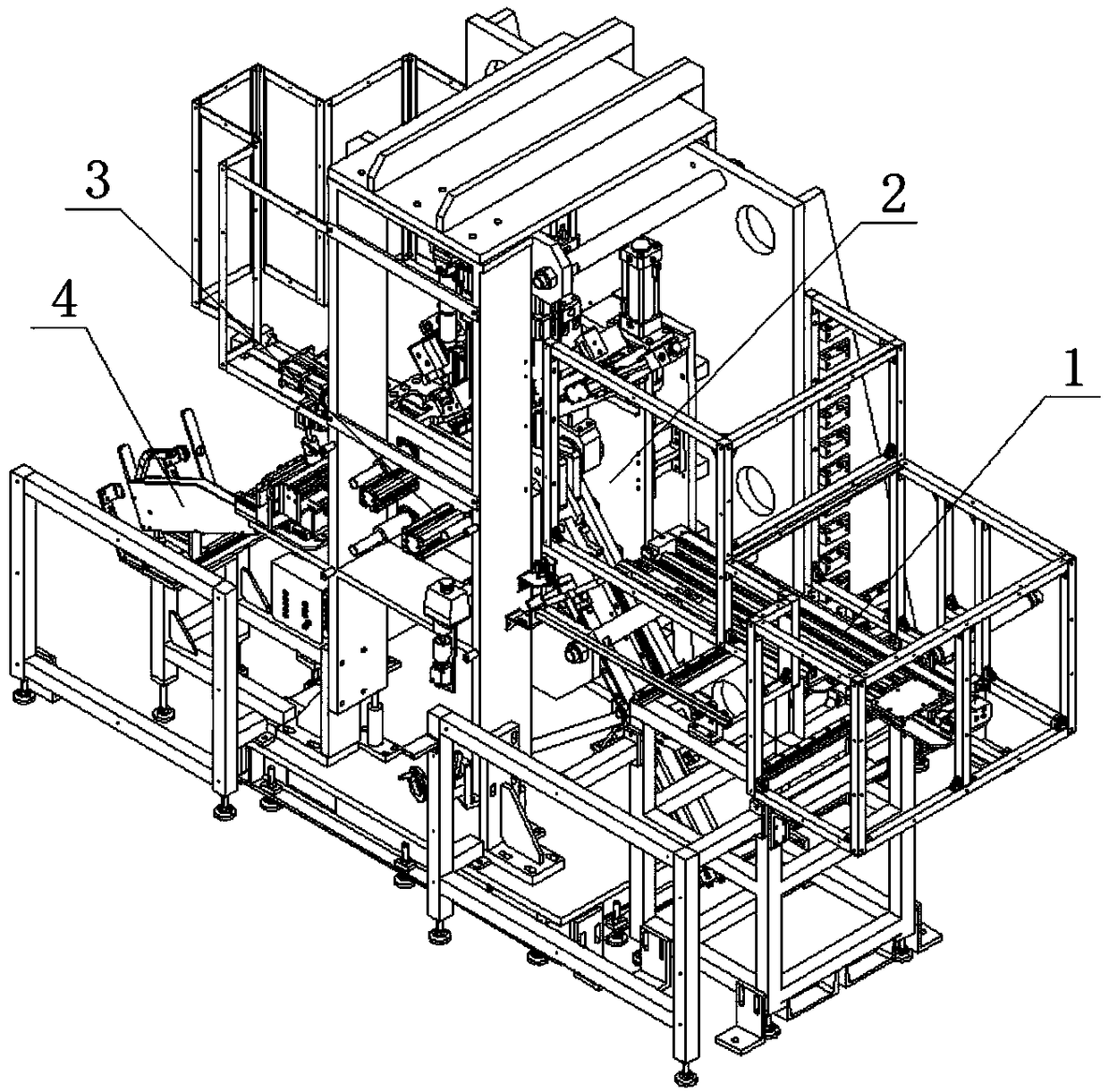

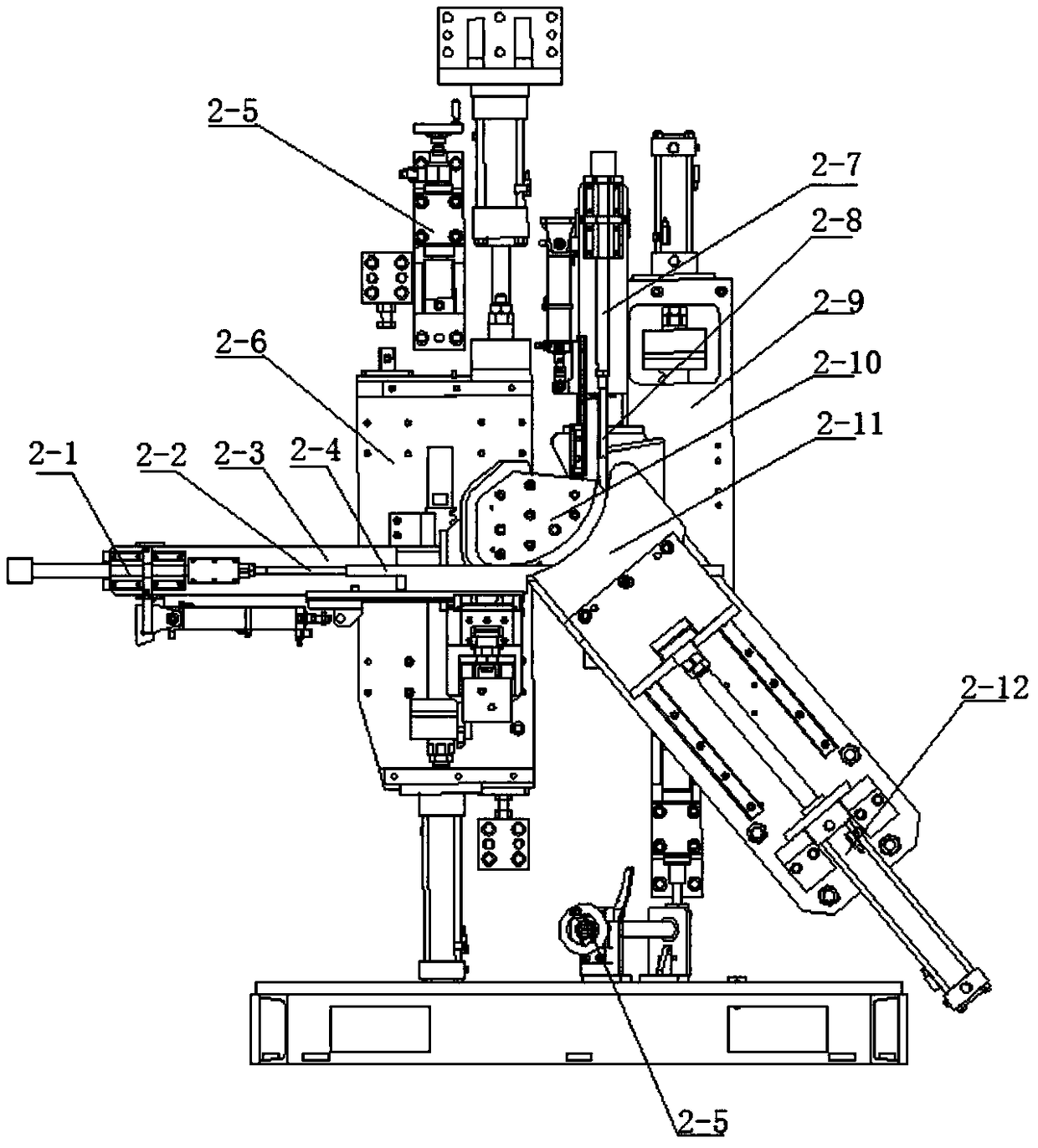

[0026] A fully automatic pipe fitting bending machine, comprising a pipe fitting input and transfer unit 1 , a pipe fitting clamping unit 3 , a bending unit 2 , and a finished product taking out unit 4 .

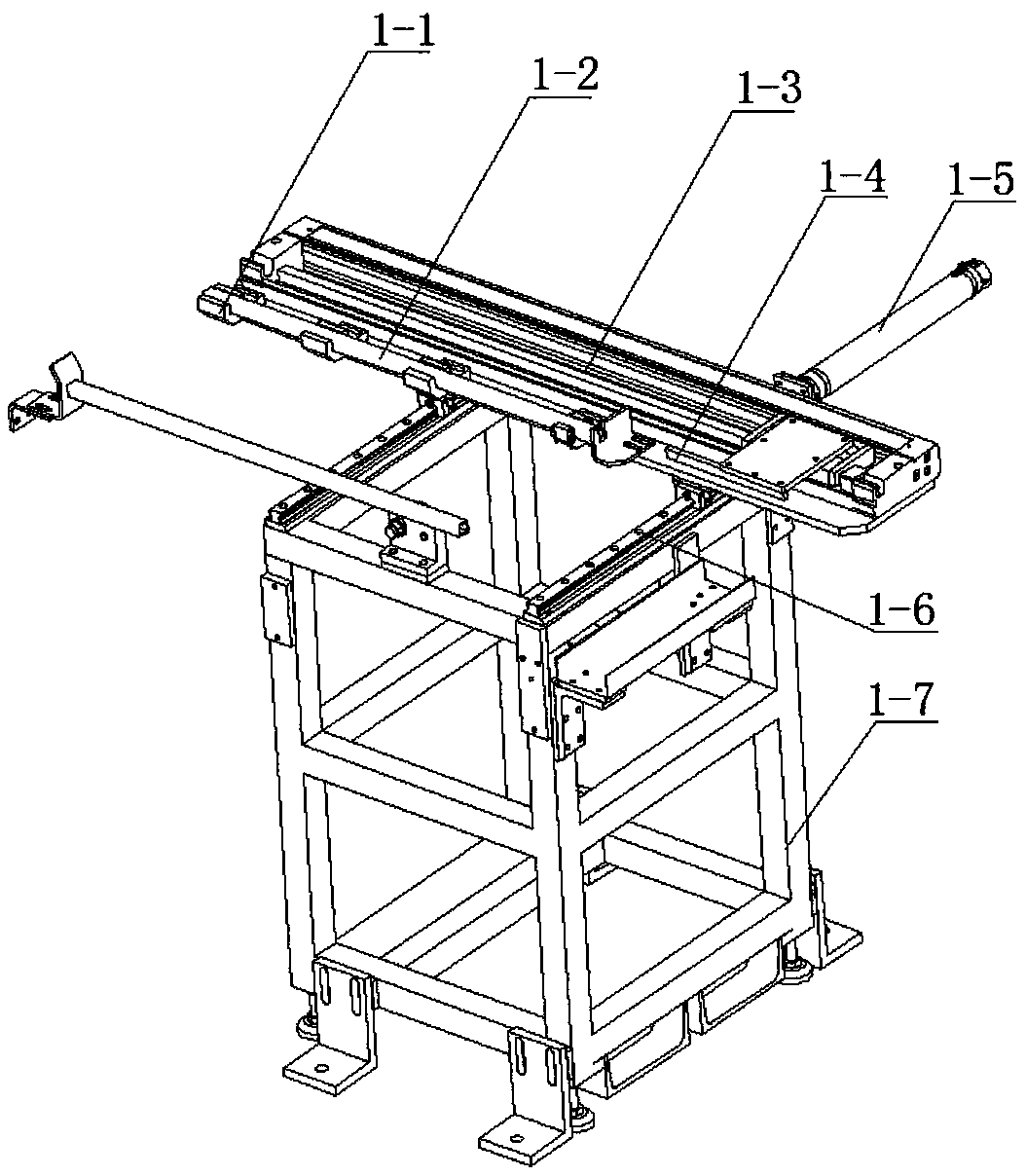

[0027] The pipe fitting input transfer unit includes a reclaiming cylinder 1-5, a pusher rodless cylinder 1-3, and two guide rails 1-6 are fixed on the top surface of the frame 1-7 in parallel and spaced apart, and are slidably installed between the two guide rails. A support plate, the rear end of the support plate is connected with a reclaiming cylinder, the reclaiming cylinder pushes the support plate to slide back and forth, a push rodless cylinder is fixed on the support plate, and a push rodle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com