Bending device for forming front and back plates of refrigerator

A technology of bending device and front and rear plates, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to perform continuous bending, affect work efficiency, and delay time for loading and unloading, so as to improve bending efficiency , to avoid the effect of material jam and continuous bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

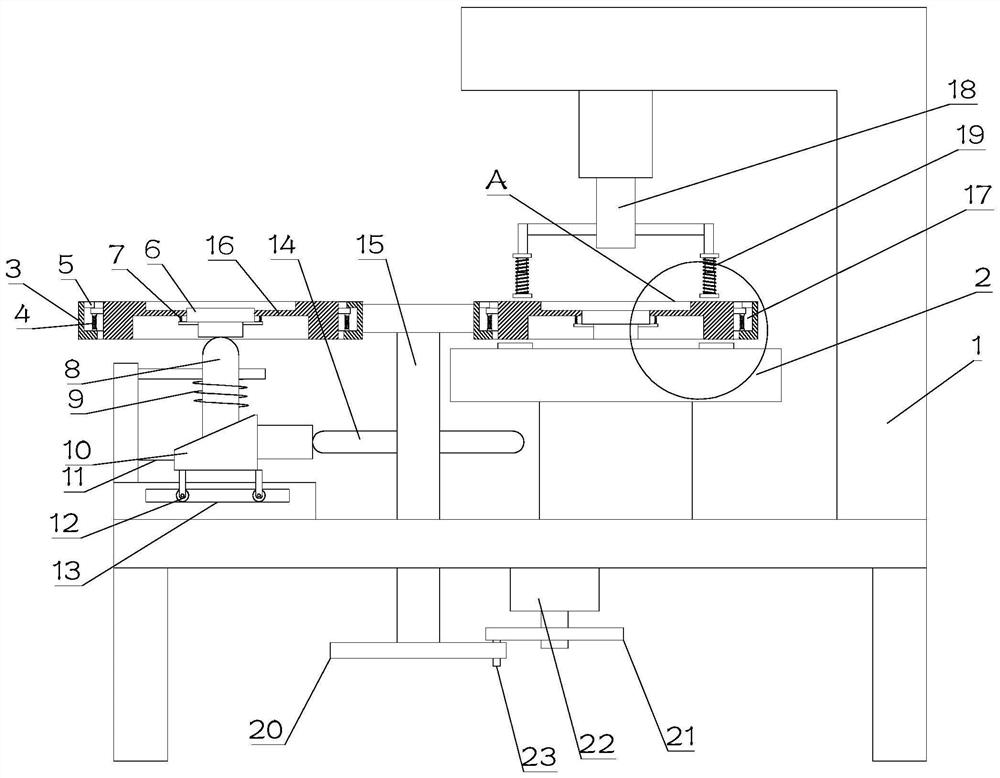

[0024] see Figure 1~3 , in Embodiment 1 of the present invention, a structural diagram of a bending device for forming the front and rear panels of a refrigerator provided in the embodiment of the present invention, including: a device base 1 and a bearing part mounted on the device base 1 in intermittent rotation;

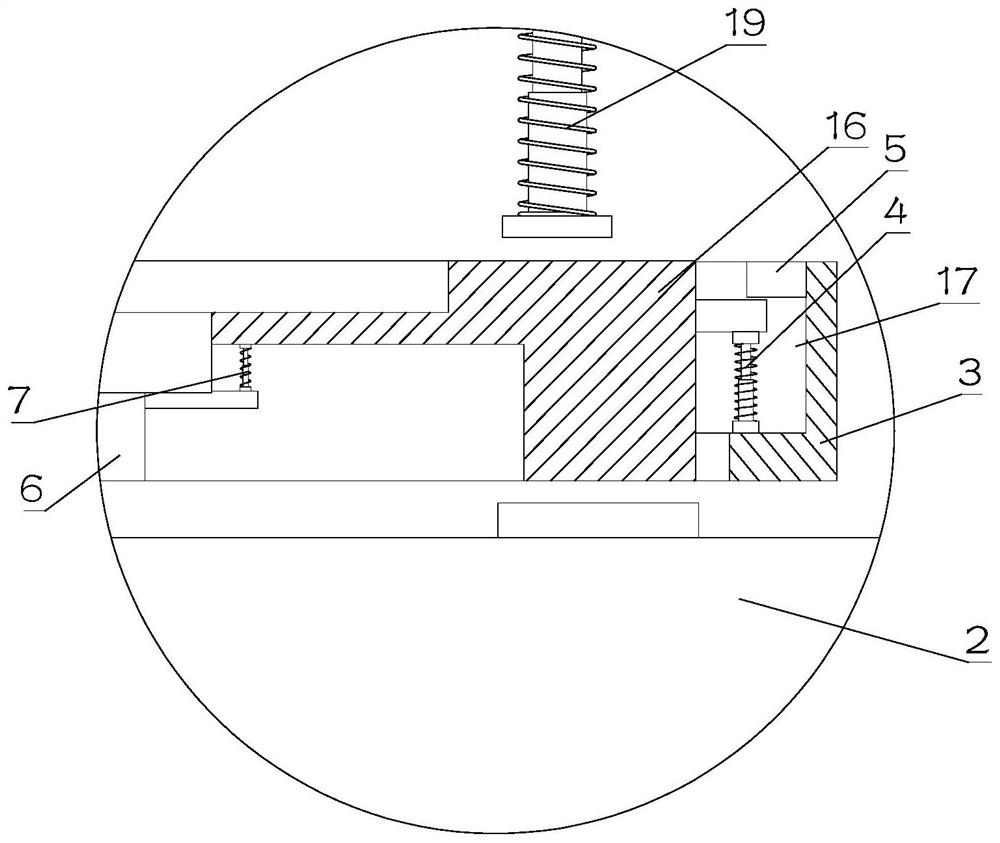

[0025] The carrying part includes an intermittently rotating support shaft 15 and a turntable 3 fixedly mounted on the upper end of the support shaft 15. The turntable 3 is provided with no less than three installation slots 17 in an array, and the interior of the installation slots 17 is elastic. A placement mold 16 is provided; the middle position of the placement mold 16 is provided with an ejector 6, and the ejector 6 is arranged on the through hole at the middle position of the placement mold 16, and the ejector 6 is elastically mounted on the placement mold 16 superior;

[0026] Wherein, the device base 1 is provided with a lifting rod 8, and the supportin...

Embodiment 2

[0030] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the first elastic support 4 is fixedly installed on both sides of the placement mold 16, and the lower end of the first elastic support 4 is fixedly installed on the installation groove 17. In this way, it is realized that the placement mold 16 is elastically installed in the installation groove 17 .

[0031] In order to prevent the elevating rod 8 from moving upward when the elevating rod 8 is on the ejector part 6, the two sides of the installation groove 17 are also provided with limiting projections 5, which are in contact with the two sides of the placing mold 16. On the edge, thus restricting the upward movement of the placement mold 16.

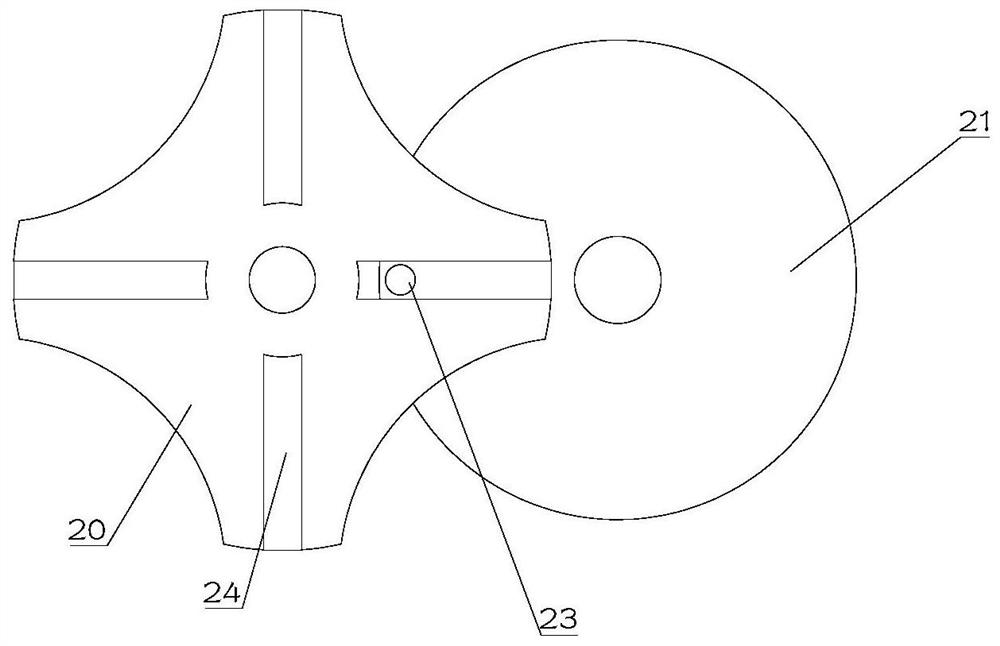

[0032] As a preferred embodiment of the present invention, the driving mechanism includes a plurality of driving rods 14 arranged on the supporting rotating shaft 15, and the driving rods 14 have the same number as the placement molds 16; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com