Continuous rolling type steel rail bending machine

A bending machine and rolling type technology, which is applied in the field of continuous rolling rail bending machine, can solve the problems of long occupation time of auxiliary equipment, unsafe manual operation, discontinuous curvature radius, etc., and achieve convenient and quick replacement of roller sleeves , Reduce labor intensity, and the effect of accurate molding curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

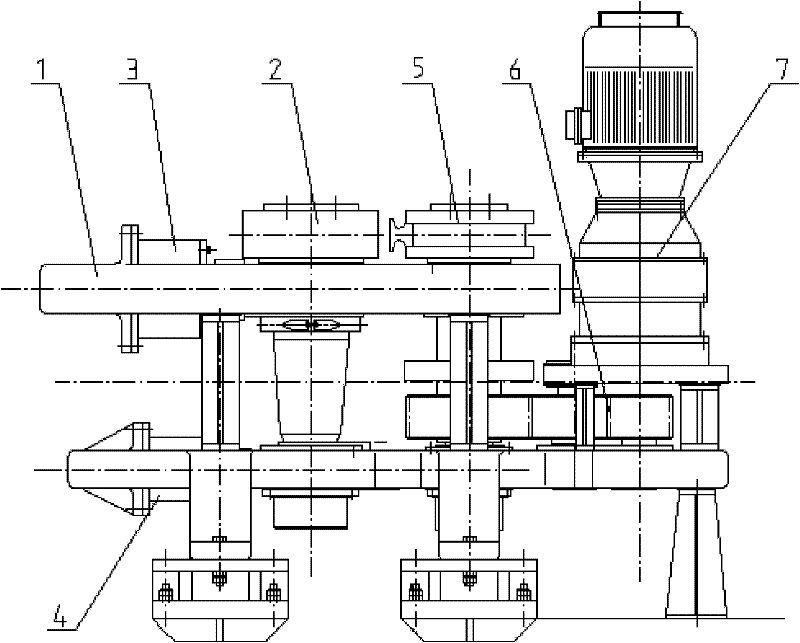

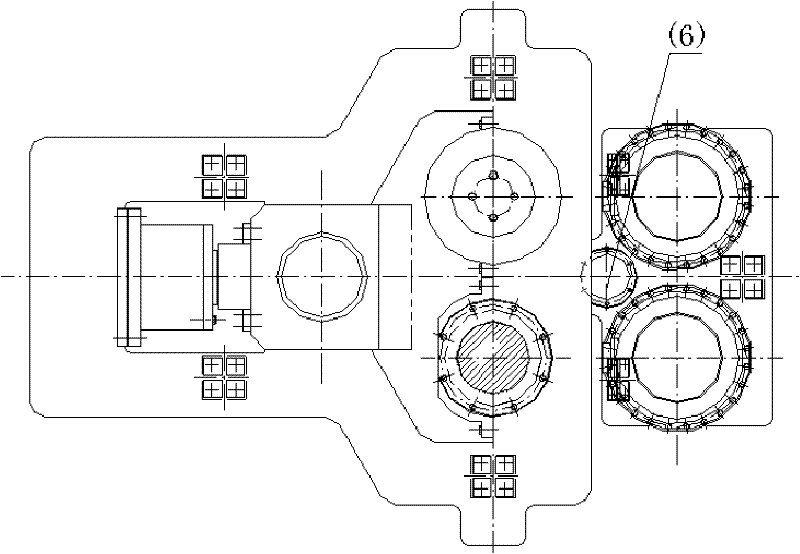

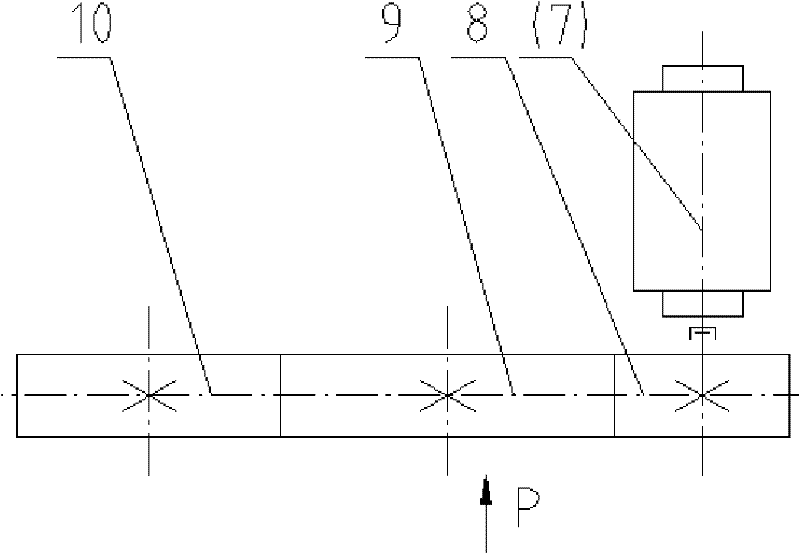

[0027] Such as figure 1 , 2 The shown continuous rolling type rail bending machine is mainly composed of frame assembly 1, pressing roller assembly 2, pressing oil cylinder I 3, pressing oil cylinder II 4, transmission roller assembly 5, intermediate gear transmission mechanism 6, Vertical electric reducer 7 and other components. The intermediate gear transmission mechanism consists of two small gears, an intermediate gear and two large gears. The two small gears are respectively installed on the output shafts of the two vertical electric reducers, and the two vertical electric reducers pass through their respective shafts. The pinion gear drives an intermediate gear together, and the two large gears are respectively installed on the transmission roller assembled by the two transmission rollers, and an intermediate gear drives a transmission roller assembled by the transmission roller through the two large gears to realize two transmissions. The rollers rotate in the same d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com