Rice micro-ridge mixed sowing cultivation method

A cultivation method and rice technology, applied in the fields of rice cultivation, agricultural gas emission reduction, animal husbandry, etc., can solve the problems of affecting farming, water shortage in soaking fields, low utilization rate, etc., and achieve the effect of promoting rapid growth and promoting seedling growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

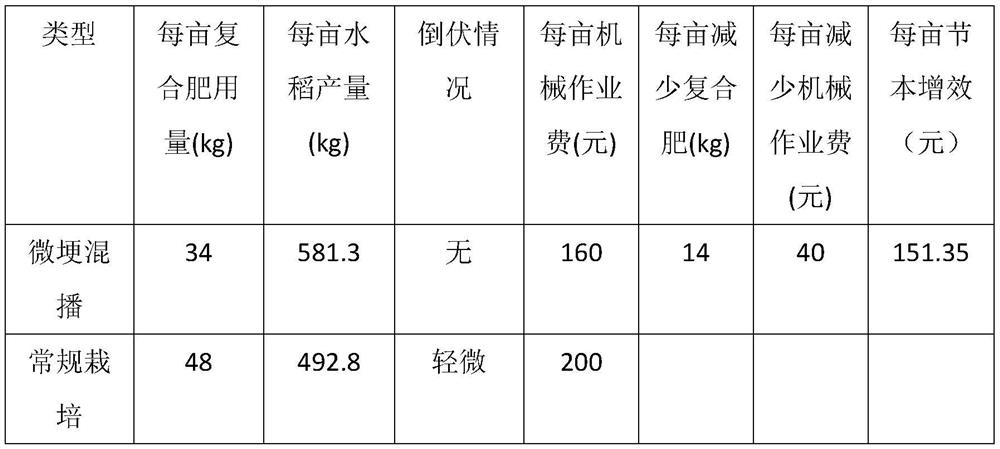

[0060] From March 2019 to July 2019, the early rice micro-ridge mixed seeding cultivation was carried out in Quantang Group, Mingyue Village, Lukou Town, Changsha County, Changsha City, Hunan Province:

[0061] 1. The previous stubble was cabbage, which was harvested on April 7. The ditch was cleared and drained on that day, and the soil surface was wet, but four-wheel tractors could work.

[0062] 2. The broken leaves left by the cabbage will not be removed, and become the rhizosphere layer of rice growth.

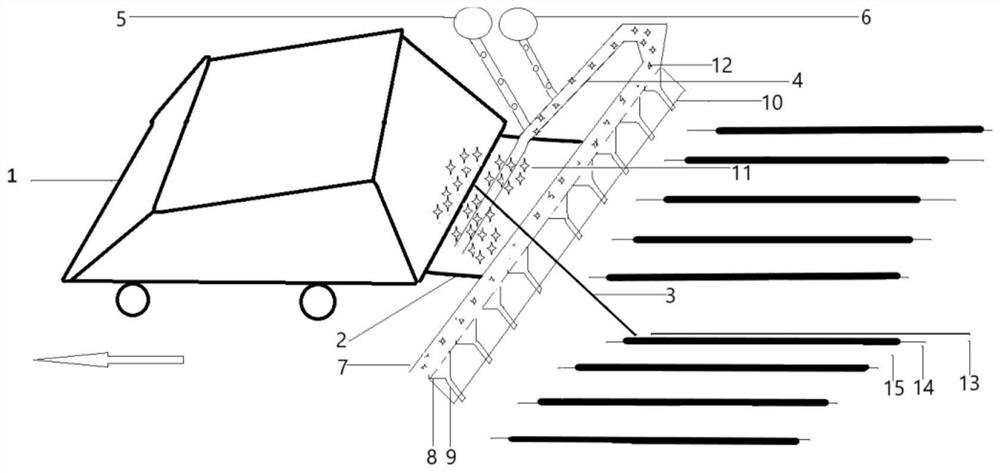

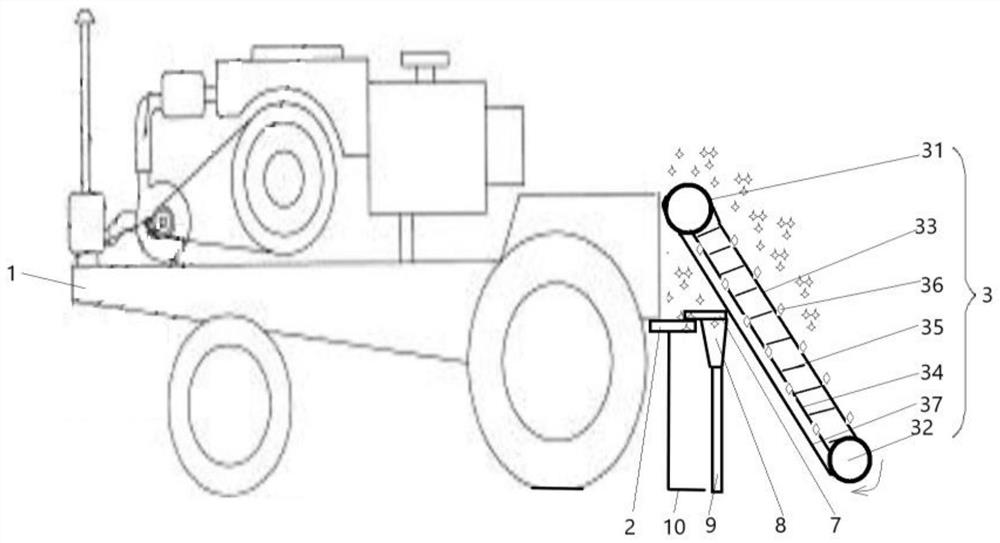

[0063] 3. Sowing with a micro-ridge mixer: 1) Ditching with a chain opener to lift out the soil in the field to form a ditch. The groove spacing is 8 meters, the groove depth is 45 cm, and the groove width is 12 cm. Most of the raised soil becomes the raw material for mixed sowing, and the sowing material is composed of rice seeds, chemical fertilizers and soil to form a composite. When sowing, mix the germinated and dewy seeds, chemical fertilizers, and the soil raised...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com