Vibrating screen self-aligning roller bearing

A technology of self-aligning roller bearings and vibrating screens, which is applied in the field of mechanical equipment, can solve the problems of low rotating speed of vibrating screen bearings, short service life of bearings, and poor impact resistance, and achieve increased service life, good friction resistance, and strong stretch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

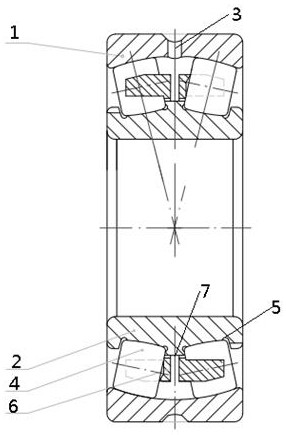

[0023] Example 1, such as figure 1 As shown, a vibrating screen spherical roller bearing includes an outer ring 1, an inner ring 2 located inside the outer ring 1, a double-row rolling device is arranged between the outer ring 1 and the inner ring 2, and the The inner ring 2 is provided with a double-row raceway 5, and the protrusion on the inner ring 2 between the double-row raceways 5 is a high guiding middle diameter 7, and the double-row rolling device includes a double-row rolling body 4 and a The double-row cage 6 supporting the double-row rolling elements 4 is placed on the double-row raceways 5 and moves on the double-row raceways 5 .

[0024] In this embodiment, the double-row raceways 5 on the inner ring 2 are arranged symmetrically with respect to the high-guiding middle diameter 7 .

[0025] In this embodiment, three equally divided oil injection holes 3 are provided on the outer ring 1 .

[0026] In this embodiment, the outer ring 1 is in the shape of an arc.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com