Method for operating a fuel system of an internal combustion engine

A fuel system and internal combustion engine technology, applied in the direction of charging systems, fuel injection pumps, fuel injection devices, etc., can solve the problems of high-pressure pump no delivery, high fuel temperature, etc., and achieve the effect of improving durability and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

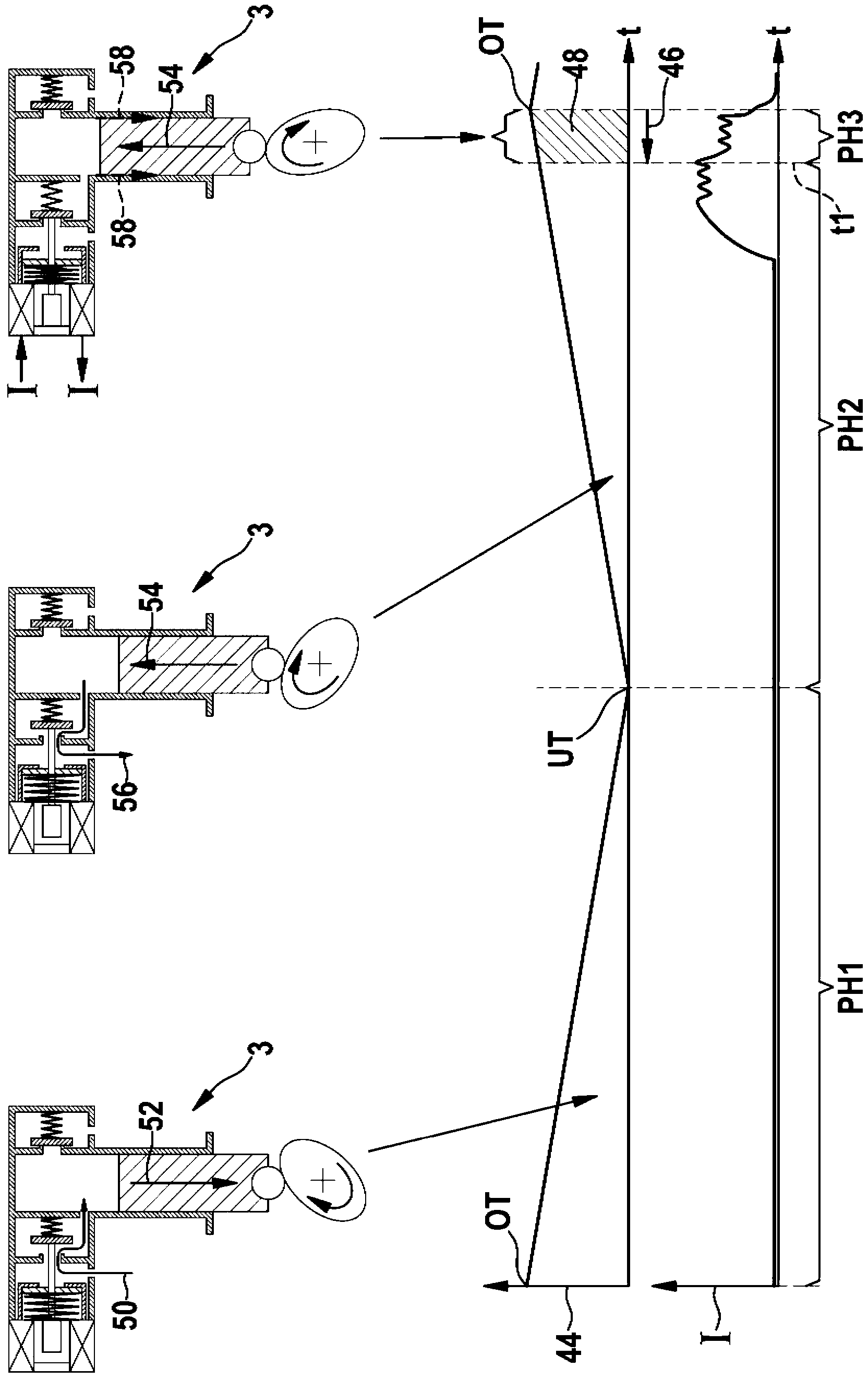

[0034] figure 1 The fuel system 1 of an internal combustion engine is shown in an extremely simplified schematic diagram. A fuel tank 9 is connected to a fuel pump 3 via a suction line 4 , a forward delivery pump 5 and a low-pressure line 7 . A high-pressure accumulator 13 (“common rail”) is connected to the fuel pump 3 via a high-pressure line 11 . The high-pressure line 11 and the high-pressure accumulator 13 together form a pressure region 16 of the fuel system 1 . A solenoid-actuated on-off valve 14—referred to below as valve unit—and a solenoid-actuated device 15—referred to below as solenoid 15—are hydraulically arranged at the low pressure between prefeed pump 5 and fuel pump 3 In the distribution area of the catheter. Electromagnet 15 is controlled by a computer program 8 of a control and / or regulating device 19 using characteristic diagram 6 . Furthermore, the fuel pump 3 includes a cam 17 arranged on the drive shaft 10 which moves a piston 18 vertically in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com