Automatic assembling device for nozzle closure of small solid rocket engine

An automatic assembly device and engine nozzle technology, which is applied in the direction of mechanical equipment, material gluing, connecting components, etc., can solve the difficulty of controlling the consistency of sealing performance and pressure bearing capacity, the difficulty of controlling the consistency of plugging pressure, and the difficulty of manual pasting and other problems, to achieve the effect of improving the sealing of the plug and the consistency of the pressure bearing capacity, realizing the rapid vertical clamping and positioning, and improving the efficiency of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

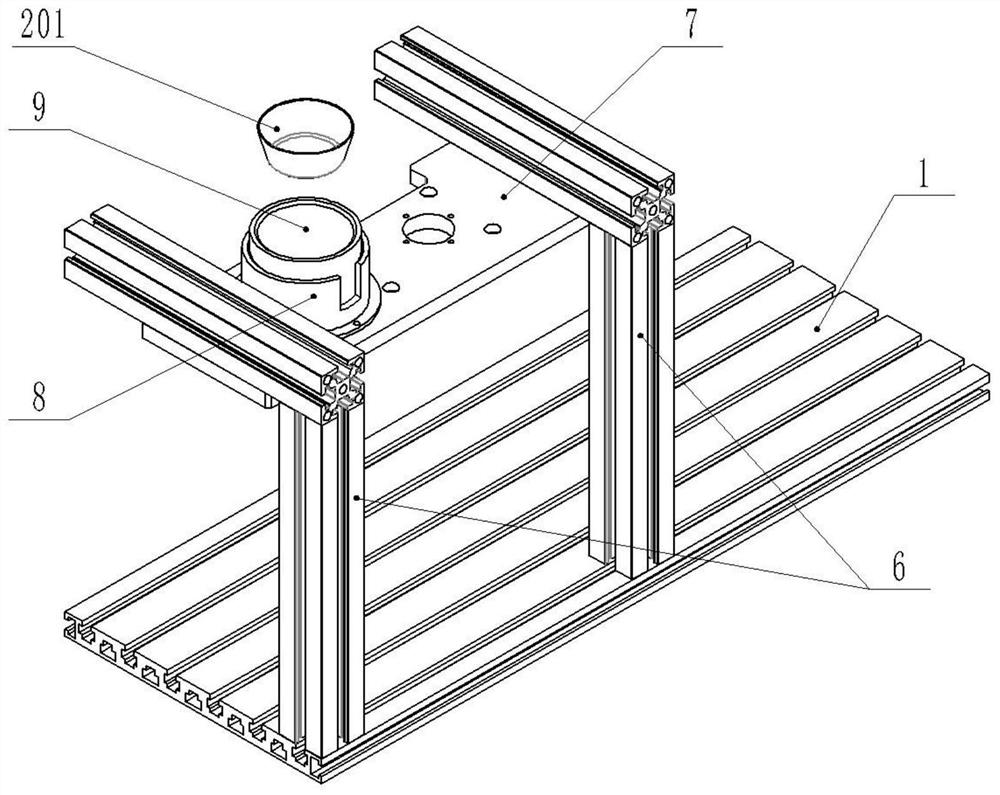

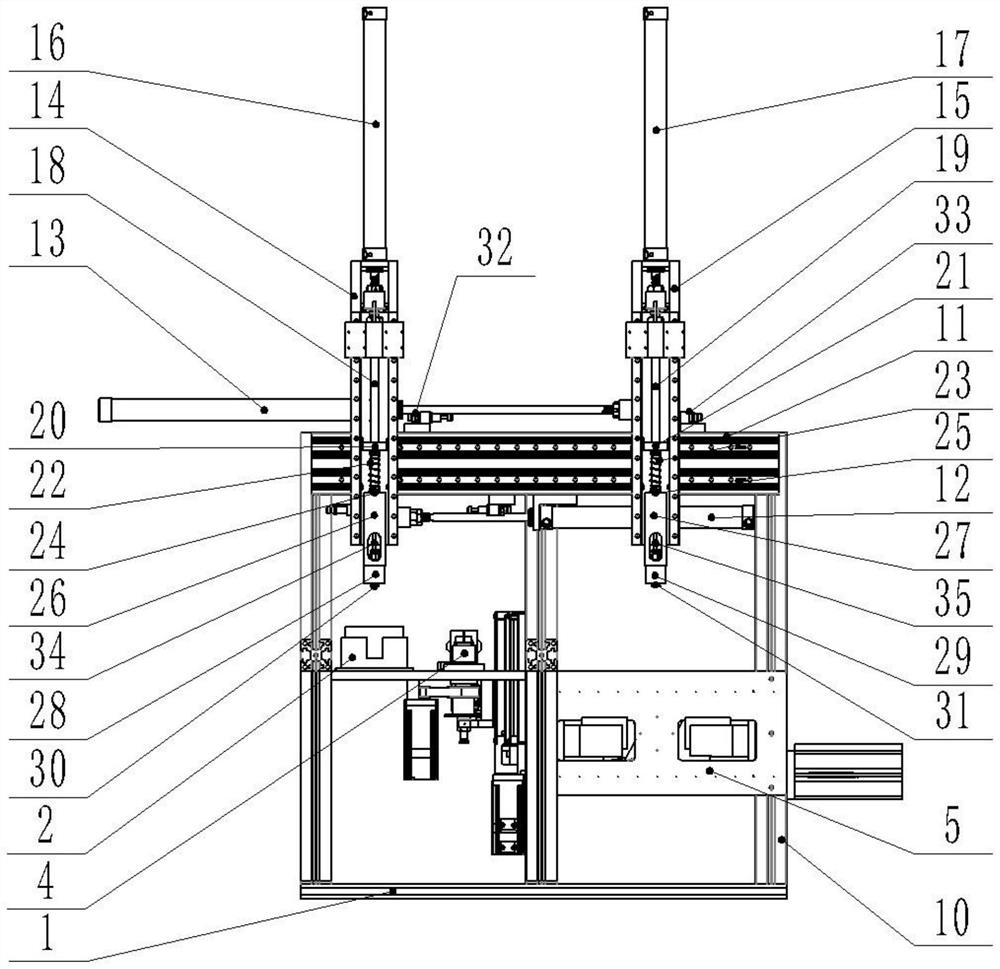

[0039] Such as figure 1 As shown, a small-sized solid rocket motor nozzle cap automatic assembly device includes a base plate 1, a cap storage mechanism 2, a double-station cap transfer mechanism 3, an automatic glue application mechanism 4, and a nozzle clamping and limiting mechanism 5, The cap storage mechanism 2 is arranged on the bottom plate 1, and is used to provide caps to the double-station cap transport mechanism 3; the double-station cap transport mechanism 3 is used to transport the caps in the cap storage mechanism 2 to the automatic coating The gluing mechanism applies glue at 4 places and transports the glued cap to the nozzle clamping limit mechanism 5 for pasting and compacting the cap; the automatic gluing mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com