Fender compression performance detection device

A detection device and fender technology, which are applied in the field of fender compression performance detection devices, can solve the problems such as the location limitation of the fender compression detection, the inability to meet the compressibility detection of the fender circumference, and the inability of the relative position of the fender to be fixed. , to achieve the effect of firm clamping, reasonable structure and increased contact friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

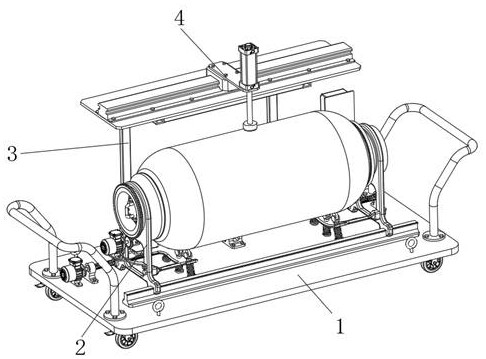

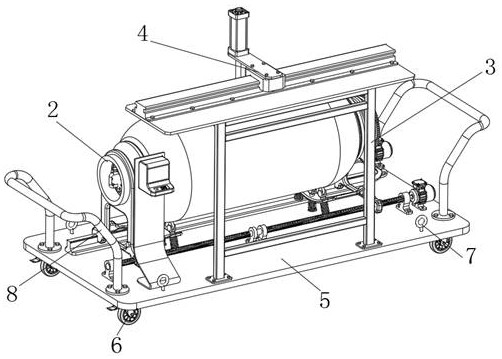

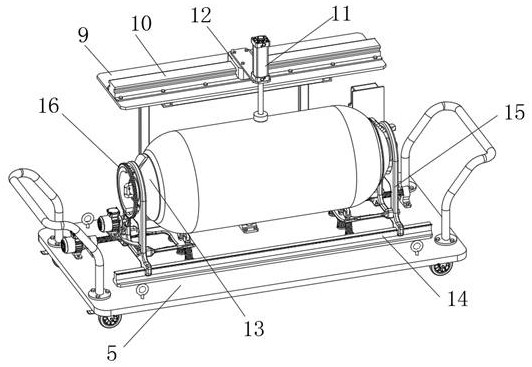

[0030] Example: Reference Figure 1-8 A fender compression performance testing device shown includes a mobile platform assembly 1, a fender limit clamping unit 2 and a frame 3 are installed on the top of the mobile platform assembly 1, and a movable fender is installed on the frame 3 The compression detection component 4, the fender compression detection component 4 is used to detect the compression performance of the fender;

[0031] The fender limit clamping unit 2 includes a connected moving assembly, a rotating clamping assembly and a support assembly 25, the moving assembly is used to move the rotating clamping assembly to clamp and limit the fender, and the rotating clamping assembly is used to clamp the fender The fender is rotated, and the support assembly 25 is used to support the fender;

[0032]It also includes a controller, the fender limit clamping unit 2 and the fender compression detection component 4 are connected to the controller signal;

[0033] Support as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com