Oxide type ceramic composite nanofiber solid electrolyte and electrostatic spinning preparation method thereof

A solid electrolyte and ceramic composite technology, applied in electrospinning, fiber processing, rayon manufacturing, etc., can solve the problem of affecting the ionic conductivity of composite solid electrolytes, affecting the ion-conducting effect of composite solid electrolytes, and the inability to form continuous ion transmission paths, etc. problem, to achieve the effect of easy control and realization of reaction conditions, good electrochemical performance and mechanical flexibility, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] An electrospinning preparation method of an oxide-type ceramic composite nanofiber solid electrolyte, the specific steps of the method are as follows:

[0059] (1) Preparation of oxide-type ceramic nanoparticles: 0.0078mol C 6 h 8 o 7 ·H 2 O, 0.007mol LiOH, 0.003mol La(NO 3 ) 3 ·6H 2 O, 0.00175mol ZrO(NO 3 ) 2 ·xH 2 O, 0.00024mol Al(NO 3 ) 3 9H 2 O was dissolved in 10ml of deionized water to obtain a homogeneous solution under stirring and heating (50°C, the same below). After drying the sol at 250 °C for 3 h, a brown porous gel was obtained. calcining the dried gel in a muffle furnace at 850° C. for 2 hours in air to obtain oxide-type ceramic nanoparticles;

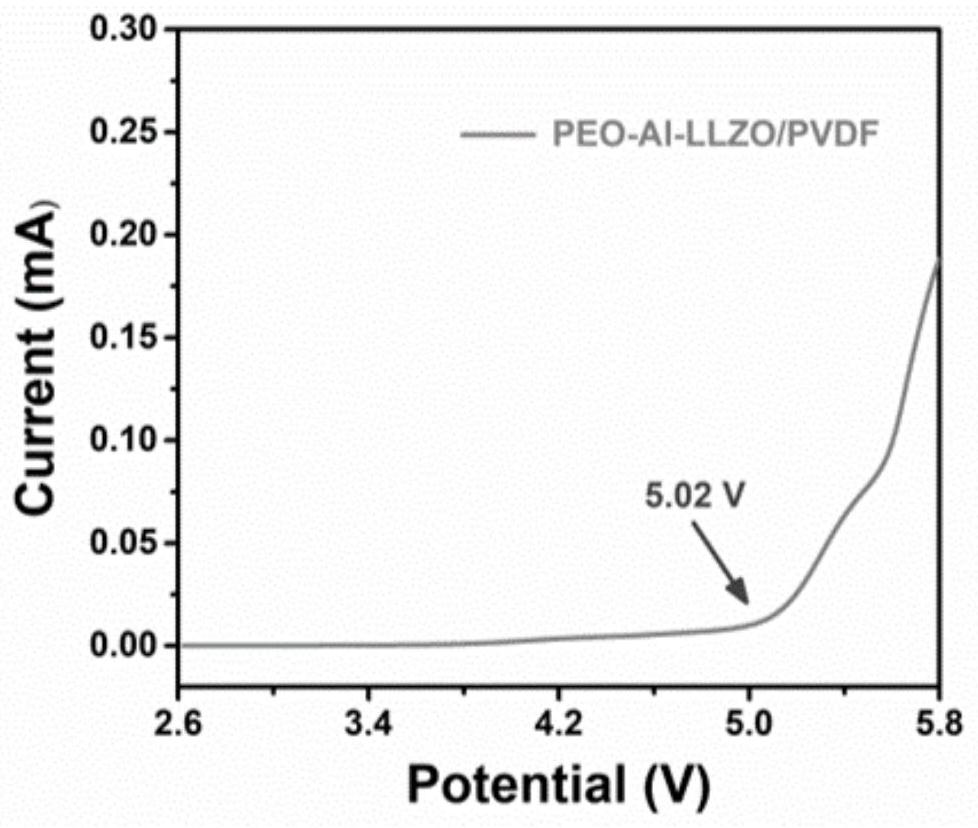

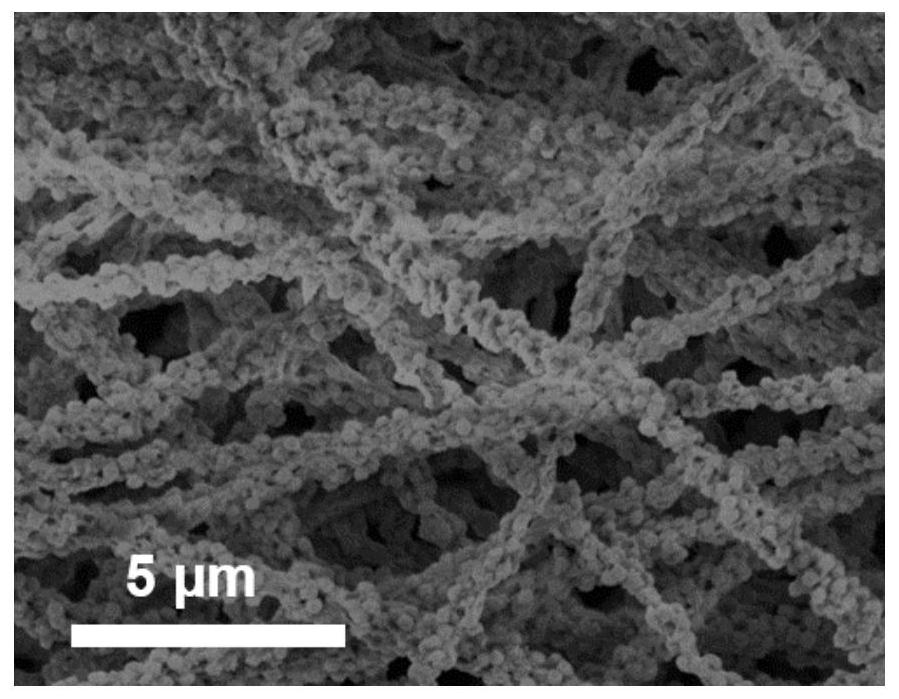

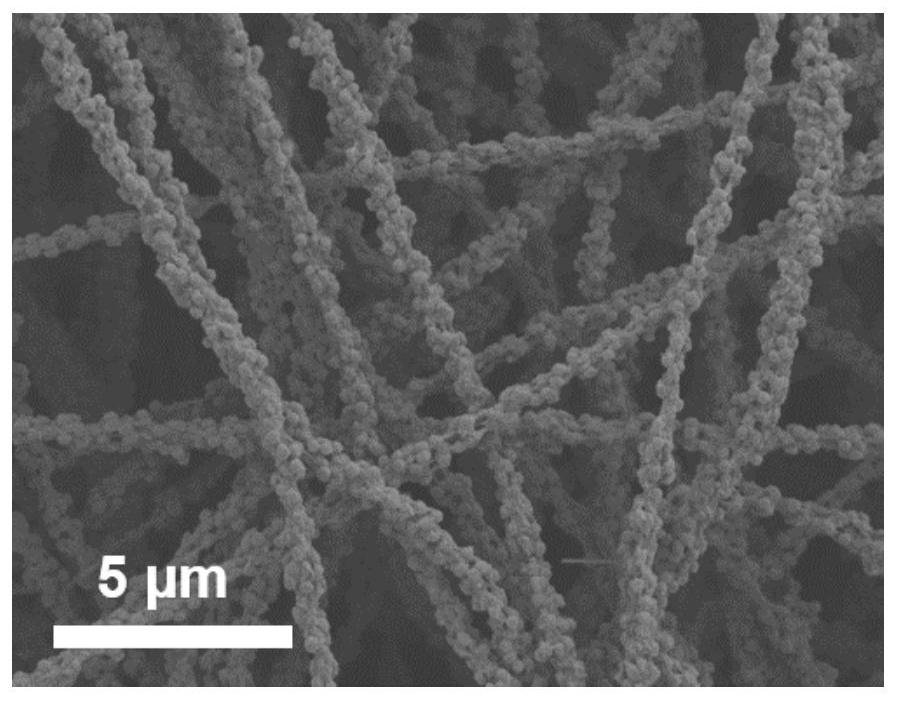

[0060] (2) Preparation of oxide-type ceramic composite nanofibers: Dissolve 0.8g polyvinylidene fluoride in 9.2g N,N-dimethylformamide solvent and stir at 60°C for 24h to obtain 8wt.% uniform polyvinylidene difluoride Vinyl fluoride solution; disperse 0.3g of ceramic nanoparticles in polyvinylidene f...

Embodiment 2

[0064] An electrospinning preparation method of an oxide-type ceramic composite nanofiber solid electrolyte, the specific steps of the method are as follows:

[0065] (1) Preparation of oxide-type ceramic nanoparticles: 0.0078mol C 6 h 8 o 7 ·H 2 O, 0.007mol LiOH, 0.003mol La(NO 3 ) 3 ·6H 2 O, 0.00175mol ZrO(NO 3 ) 2 ·xH 2 O, 0.00025mol NbCl 5 Dissolve in 10 ml of deionized water under stirring and heating to obtain a homogeneous solution. After drying the sol at 250 °C for 3 h, a brown porous gel was obtained. calcining the dried gel in a muffle furnace at 850° C. for 2 hours in air to obtain oxide-type ceramic nanoparticles;

[0066] (2) Preparation of oxide-type ceramic composite nanofibers: Dissolve 0.8g polyvinylidene fluoride in 9.2g N,N-dimethylformamide solvent and stir at 60°C for 24h to obtain 8wt.% uniform polyvinylidene difluoride Vinyl fluoride solution; disperse 0.2g ceramic nanoparticles in polyvinylidene fluoride solution, add 0.04g polyethylene oxi...

Embodiment 3

[0070] An electrospinning preparation method of an oxide-type ceramic composite nanofiber solid electrolyte, the specific steps of the method are as follows:

[0071](1) Preparation of oxide-type ceramic nanoparticles: 0.0078mol C 6 h 8 o 7 ·H 2 O, 0.007mol LiOH, 0.003mol La(NO 3 ) 3 ·6H 2 O, 0.00175mol ZrO(NO 3 ) 2 ·xH 2 O, 0.00025mol NbCl 5 Dissolve in 10 ml of deionized water under stirring and heating to obtain a homogeneous solution. After drying the sol at 250 °C for 3 h, a brown porous gel was obtained. calcining the dried gel in a muffle furnace at 850° C. for 2 hours in air to obtain oxide-type ceramic nanoparticles;

[0072] (2) Preparation of oxide-type ceramic composite nanofibers: Dissolve 0.8g polyvinylidene fluoride in 9.2g N,N-dimethylformamide solvent and stir at 60°C for 24h to obtain 8wt.% uniform polyvinylidene difluoride Vinyl fluoride solution; disperse 0.4g of ceramic nanoparticles in polyvinylidene fluoride solution, add 0.04g of polyethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com