Animal fat washing device

A water washing device and animal fat technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of interrupting the water washing process of animal fat, reducing water washing efficiency, increasing labor costs, etc., to improve purity, improve washing quality, and improve washing The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Reference Figure 1-6 , An animal fat water washing device, comprising a melting device 1, a centrifugal device 4, a water washing separation device 6, an oil pumping device 8 and a mixing device 9. A first oil pipe 3 and a centrifugal device 4 are connected between the melting device 1 and the centrifugal device 4 The second oil delivery pipe 5 is connected to the water washing and separating device 6. The inner cavity of the water washing separating device 6 is close to the second oil delivery pipe 5 and an oil pumping device 8 is provided. The inner cavity of the water washing separating device 6 is close to the side of the oil pumping device 8 A mixing device 9 is provided. The melting device 1 includes a protective cover 11 and a melting furnace 12. The side of the first oil pipe 3 close to the melting furnace 12 is arranged in the inner cavity of the melting furnace 12, and an oil pump 2 is installed in the middle of the first oil pipe 3 to melt A heating plate is ...

Embodiment 2

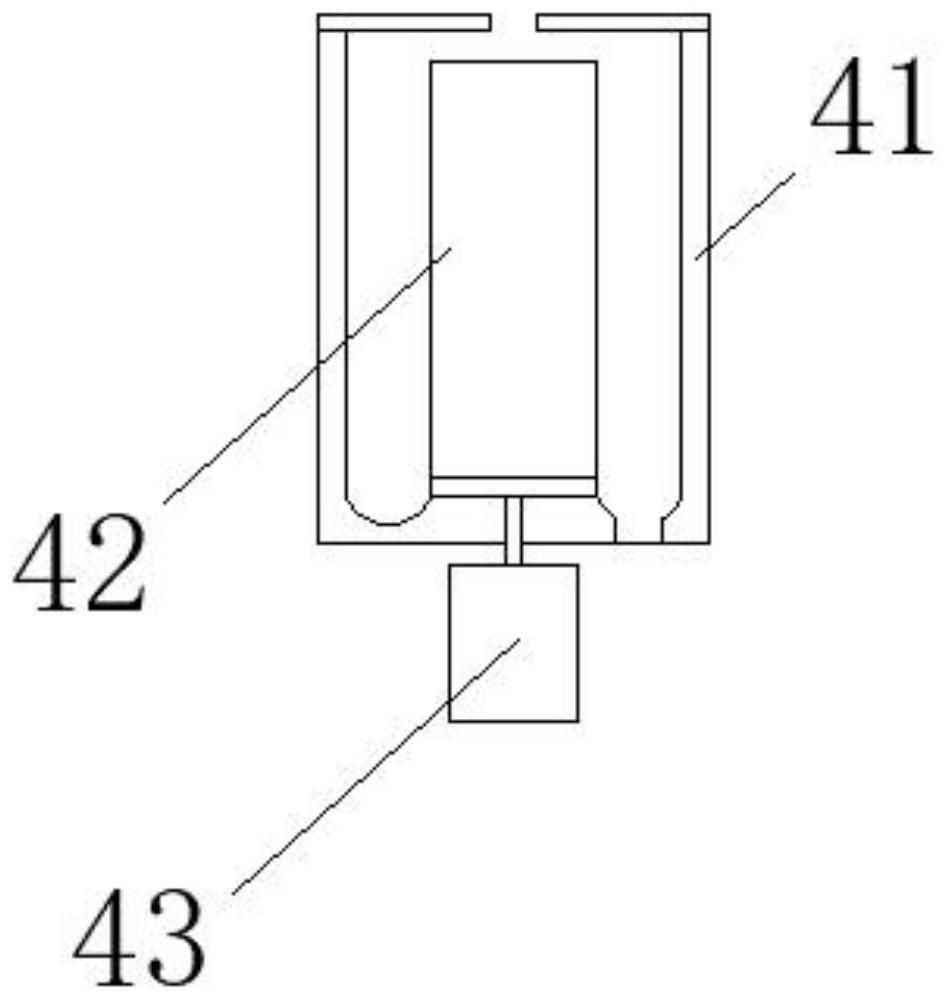

[0032] The centrifugal device 4 includes a centrifugal cylinder 41. The inner cavity of the centrifugal cylinder 41 is equipped with a rotating cylinder 42 through a bearing. The bottom of the centrifugal cylinder 41 is provided with a centrifugal motor 43. The centrifugal motor 43 is connected to the rotating cylinder 42 through a coupling. It includes a device housing 61, a buffer plate 62 is provided at the bottom of the inner cavity of the device housing 61, a water outlet 64 is provided at the bottom of one side of the device housing 61, a partition plate 63 is provided in the middle of the inner cavity of the device housing 61, a buffer plate 62 It is composed of two symmetrical orifice plates, and the positions of the holes on the two orifice plates are staggered.

[0033] The centrifugal device 4 transports the liquid grease to the water washing separation device 6 through the second oil delivery pipe 5, and the buffer plate 62 can play a buffer function to prevent the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com