Melt-blown material with high oily particle filtering efficiency, and preparation method and application of melt-blown material

A particle filtration efficiency and oily technology, applied in the medical and health field, can solve the problems of large difference in effect, low filtration efficiency, poor filtration effect of oily particles, etc., and achieve long charge retention time, uniform filtration efficiency and long retention time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

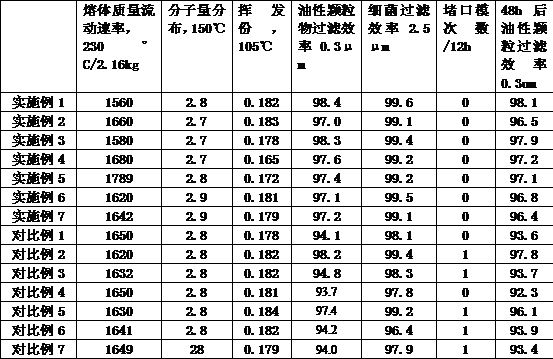

Examples

preparation example Construction

[0034] A preparation method of a high oil particle filtration efficiency melt-blown material, the steps are as follows:

[0035] Step 1: Ultrasonic crush tourmaline powder and fluoropolymer in a solvent, add oleophobic agent and mix evenly to obtain compound electret agent, filter, dry, and pulverize to obtain powdery particles.

[0036] Step 2: Put the ultra-high flow polypropylene and antioxidant into the mixer for pre-mixing for 150s; put the mixed polypropylene into the twin-screw extruder, in which the compound electret agent is mainly added through the side feeding port, extruded The melt-blown material with high oil particle filtration efficiency can be obtained.

[0037] The production process of the melt-blown cloth is as follows: melt-blown equipment, the diameter of the screw is 60mm, the screw has 6 temperature-controlled heating zones, the die head is a single die head, the number of spinneret holes is 156, and the diameter of the spinneret holes is 0.2mm;

[003...

Embodiment 1

[0042] The preparation method of the melt blown material with high oily particle filtration efficiency in Example 1 follows the following steps: Step 1: ultrasonically crush 20% tourmaline powder and 50% fluoropolymer in a solvent, and add 30% oleophobic agent Mix evenly to obtain compound electret agent, filter, dry, and grind to obtain powdery particles. Step 2: Put 98.5% ultra-high flow polypropylene and 0.5% antioxidant into the mixer for pre-mixing for 150s; put the mixed polypropylene into the twin-screw extruder, of which 1% composite electret agent mainly passes through the side The feed port is added and extruded to obtain a melt-blown material with high oily particle filtration efficiency.

Embodiment 2

[0043] The preparation method of the high oil particle filtration efficiency melt-blown material of embodiment 2 is as follows: step 1: 20% tourmaline powder and 60% fluoropolymer are ultrasonically crushed in a solvent, and 20% oleophobic agent is added Mix evenly to obtain compound electret agent, filter, dry, and grind to obtain powdery particles. Step 2: put 99.4% ultra-high flow polypropylene and 0.1% antioxidant into the mixer for pre-mixing for 150s; put the mixed polypropylene into the twin-screw extruder, of which 0.5% composite electret agent mainly passes through the side The feed port is added and extruded to obtain a melt-blown material with high oily particle filtration efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com